A Hydrostatic Bearing Used in Optical Plane Polishing Machine Tool

A static pressure bearing and optical plane technology, which is applied to the parts, bearings, shafts and bearings of grinding machine tools, can solve the problems of low production efficiency, low pass rate, high price, etc., and achieve high production efficiency and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

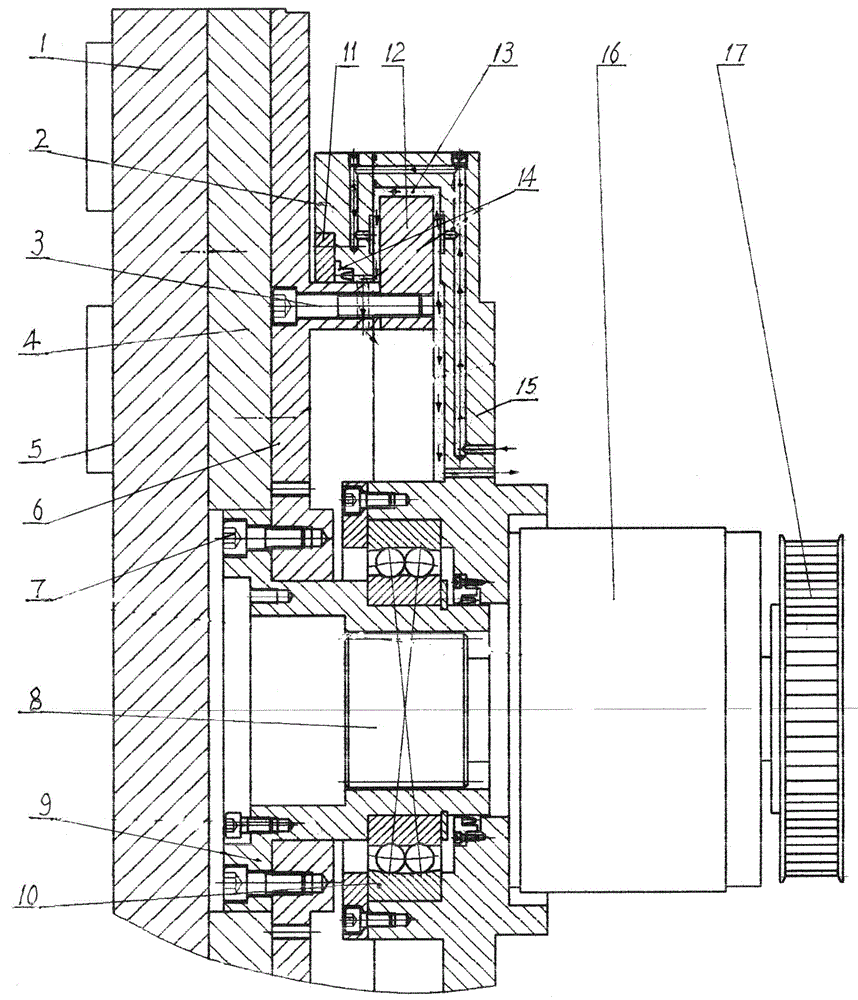

[0009] refer to figure 2 , to illustrate the main technical solutions of the present invention: the present invention consists of a polishing disc 1, a lower pressure plate 2, an inner hexagonal bolt 3, a transition disc 4, a circular boss turntable 6, a screw 7, a toothed coupling 8, and a bearing sleeve 9 , Self-aligning ball bearing 10, annular pressure plate 11, middle turntable 12, hydraulic oil 13, Y-shaped sealing ring 14, bearing base 15, reducer 16, toothed pulley 17 and so on. Its specific structure:

[0010] Ⅰ. The round boss turntable 6 is connected with the middle turntable 12 through twenty-four bolts 3 evenly distributed to form a rotating body, which is connected with the transition plate 4 and the polishing disc 1 through pins and screws, and the middle turntable 12 is installed on the bottom In the cylindrical space between the pressure plate 2 and the L-shaped bearing base 15, the intermediate turntable 12 has a gap of 0.04mm on both sides of the space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com