Online shaft neck repairing method

A repair method and journal technology, applied in the field of journal repair, can solve the problems of large production impact, large workload, and high cost, and achieve the effects of reducing difficulty, ensuring production, and good matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Such as Figure 1 to Figure 8 As shown, the journal online repair method in this embodiment includes:

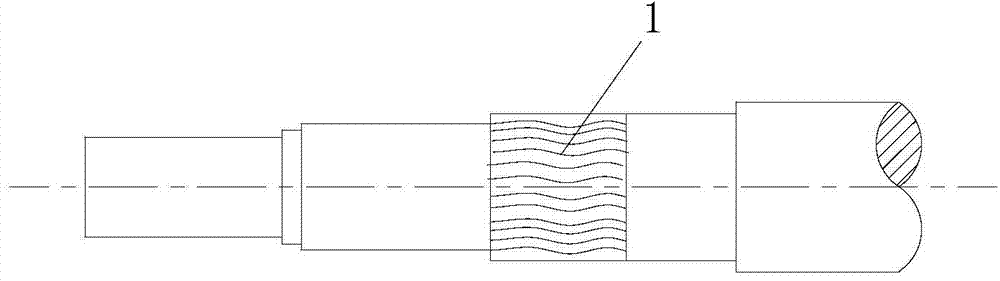

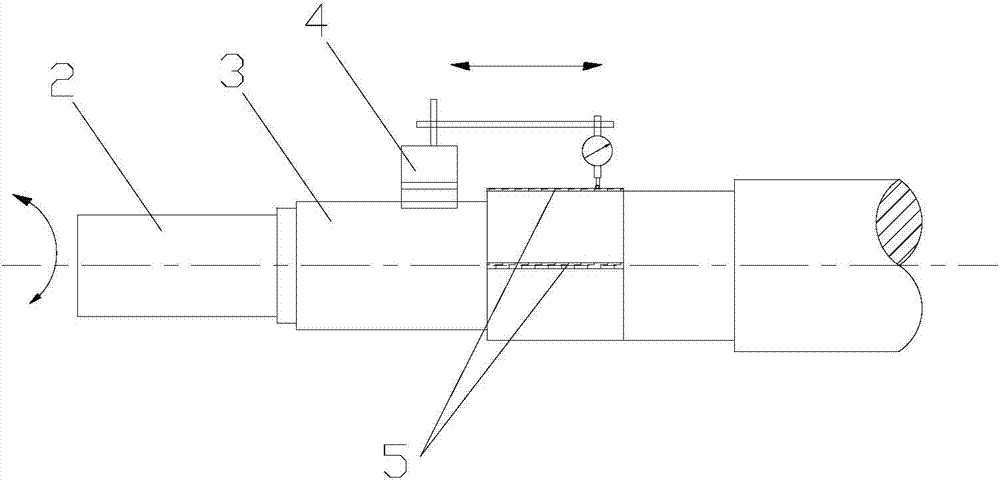

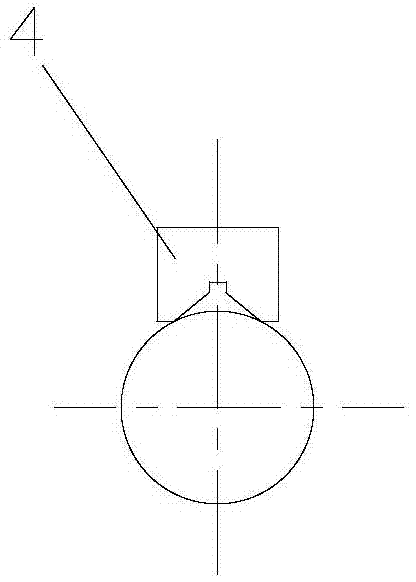

[0030] The first step is to open the upper box cover 8 of the bearing seat, cut off the damaged original bearing, and expose the journal worn by the bearing; roughly grind the worn journal 1, so that the journal diameter is 0.20-0.40mm smaller than the standard journal diameter; Four protruding welding bars 5 are welded symmetrically along the axial direction at the grinding place of the journal, the width of the welding bars 5 is 2-5mm, and there is a gap between adjacent welding bars 5; the welding bars 5 are finished, so that the welding bars 5 The runout of the outer surface relative to the axis is less than 0.03mm, and the error of the shortest distance between the outer surfaces of the symmetrical weld bars 5 is less than 0.03mm.

[0031] Among them, use a cutting tool to cut off the damaged bearing; when rough grinding, use the end cover with a semi-circular h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com