Composite carbon fiber-loaded metal catalyst as well as preparation method and application thereof

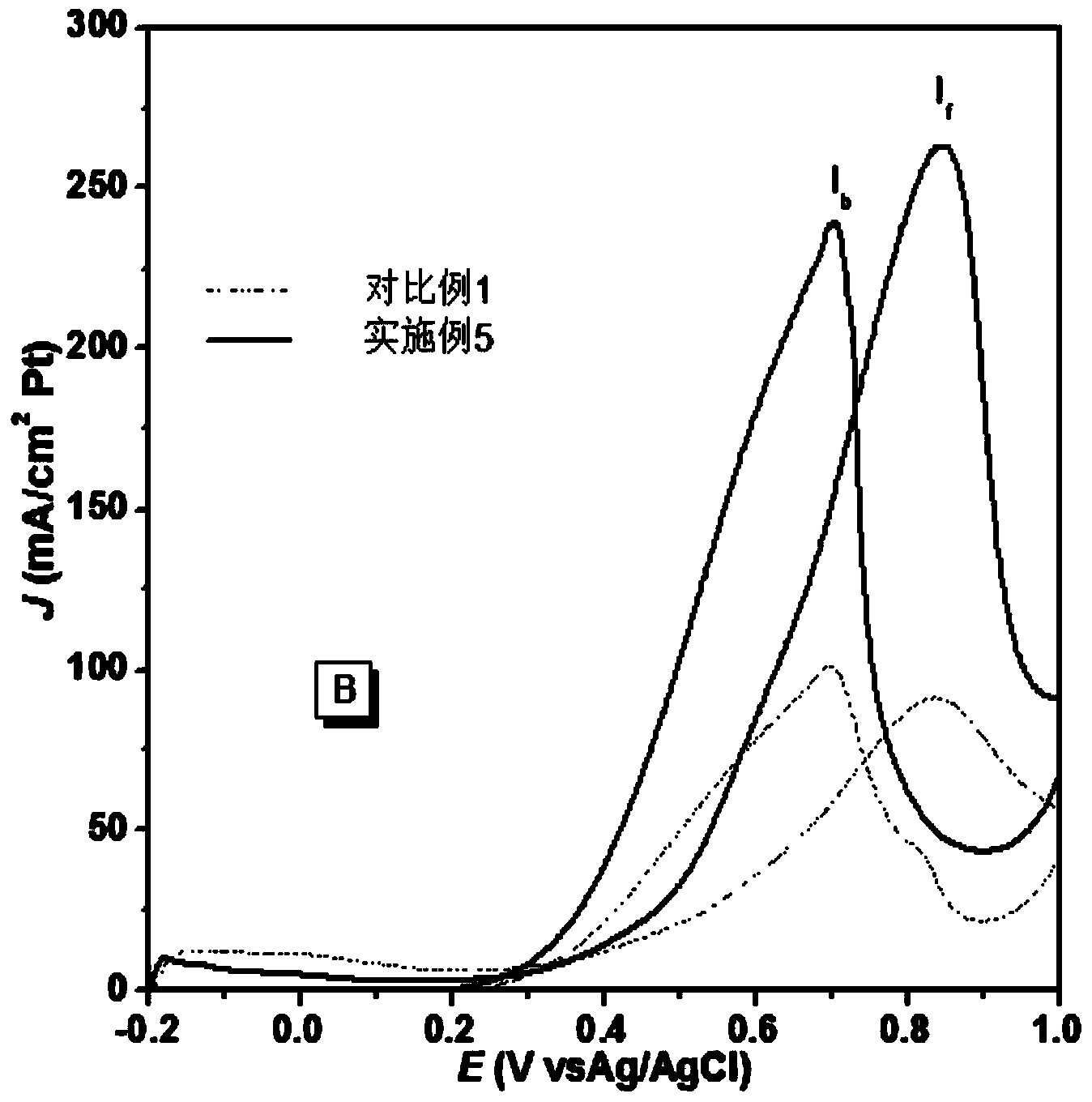

A metal catalyst and composite carbon fiber technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high conductivity and high proton conductivity, reduce catalyst conductivity, high catalytic activity, etc., to achieve improved performance, good metal Effects of dispersibility and high electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

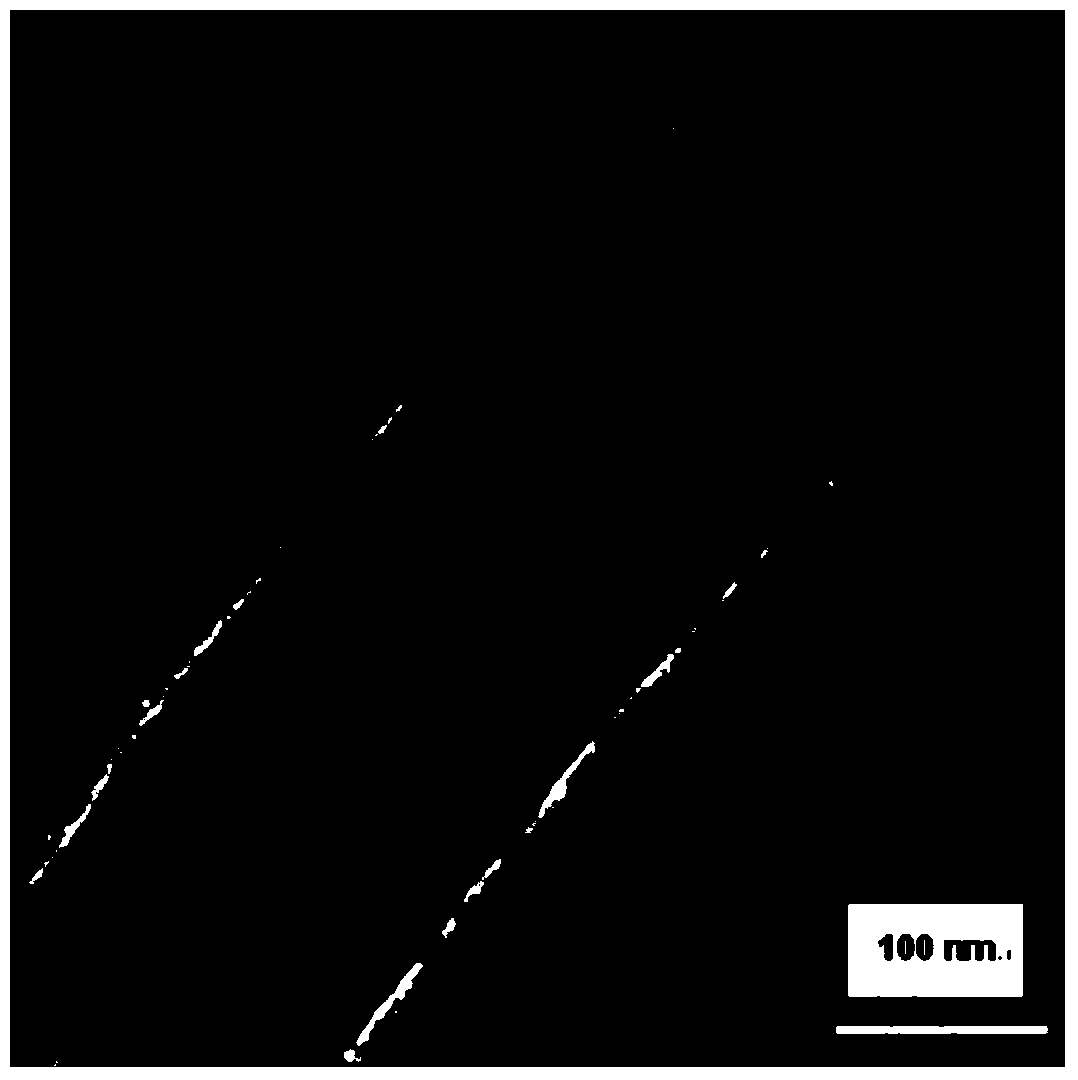

[0053] (1) Put 100mg of carbon fiber (CF) containing multi-armed carbon nanotube (MWCNT) additive into 0.2M sulfuric acid solution of potassium permanganate, the concentration of sulfuric acid is 0.5M, and stir at 40°C for more than 3h , preparing a composite carbon fiber (M-CF) uniformly loaded with spherical manganese dioxide;

[0054] (2) Put the M-CF uniformly loaded with spherical manganese dioxide obtained in (1) into a vacuum oven at 70°C and dry for 6 hours.

[0055] (3) The dried M-CF uniformly loaded with spherical manganese dioxide obtained in (3) is loaded into a ceramic boat, and placed in a quartz tube furnace to carry out a high-temperature catalytic process of carbon material graphitization, and the carbonization temperature is 850°C , the carbonization time is 3 hours, the atmosphere is a hydrogen-argon mixture, and the heating rate is 2 / min, so that the high degree of graphitization M-CF with uniform spherical manganese dioxide is obtained.

[0056] (4) Put ...

Embodiment 2

[0058] (1) Put 100mg of carbon fiber (CF) into a sulfuric acid solution of 0.5M potassium permanganate, the concentration of sulfuric acid is 0.4M, and stir at 30°C for more than 2 hours to prepare CF loaded with spherical manganese oxide uniformly;

[0059] (2) Put the graphene uniformly loaded with spherical manganese oxide obtained in (1) into a vacuum oven at 55° C., and dry for 10 h.

[0060] (3) The dry CF obtained in (3) loaded uniformly with spherical manganese oxide is loaded into a ceramic boat, and placed in a quartz tube furnace to carry out a high-temperature catalytic process of carbon material graphitization. The carbonization temperature is 900 ° C, and the carbonization time is 2h, the atmosphere is a hydrogen-argon mixture, and the heating rate is 2 / min, so as to obtain the high degree of graphitization CF of uniformly loaded spherical manganese oxide.

[0061] (4) Put 100 mg of CF with a high degree of graphitization uniformly loaded with spherical manganese...

Embodiment 3

[0063] (1) Put 100 mg of carbon fibers (CF) containing single-arm carbon nanotubes (SWCNT) into a sulfuric acid solution of 0.5M potassium dichromate, the concentration of sulfuric acid is 0.4M, and stir at 50°C for more than 1h, A carbon fiber (S-CNF) compounded with single-arm carbon tubes uniformly loaded with spherical chromium oxide is prepared;

[0064] (2) Put the S-CF uniformly loaded with spherical chromium oxide obtained in (1) into a vacuum oven at 55°C and dry for 10 hours.

[0065] (3) The dried S-CF uniformly loaded with spherical chromium oxide obtained in (3) is loaded into a ceramic boat, and placed in a quartz tube furnace to carry out a high-temperature catalytic process of carbon material graphitization. The carbonization temperature is 800 ° C. The carbonization time is 5 hours, the atmosphere is pure argon, and the heating rate is 4 / min, so that the high graphitization degree SWCNT uniformly loaded with spherical chromium oxide can be obtained.

[0066] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com