Hydraulic control device using hydraulic actuator

A technology for hydraulic actuators and control devices, which can be used in fluid pressure actuation devices, accumulator devices, fluid pressure actuation system components, etc., and can solve problems such as damage, hydraulic pressure drop, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

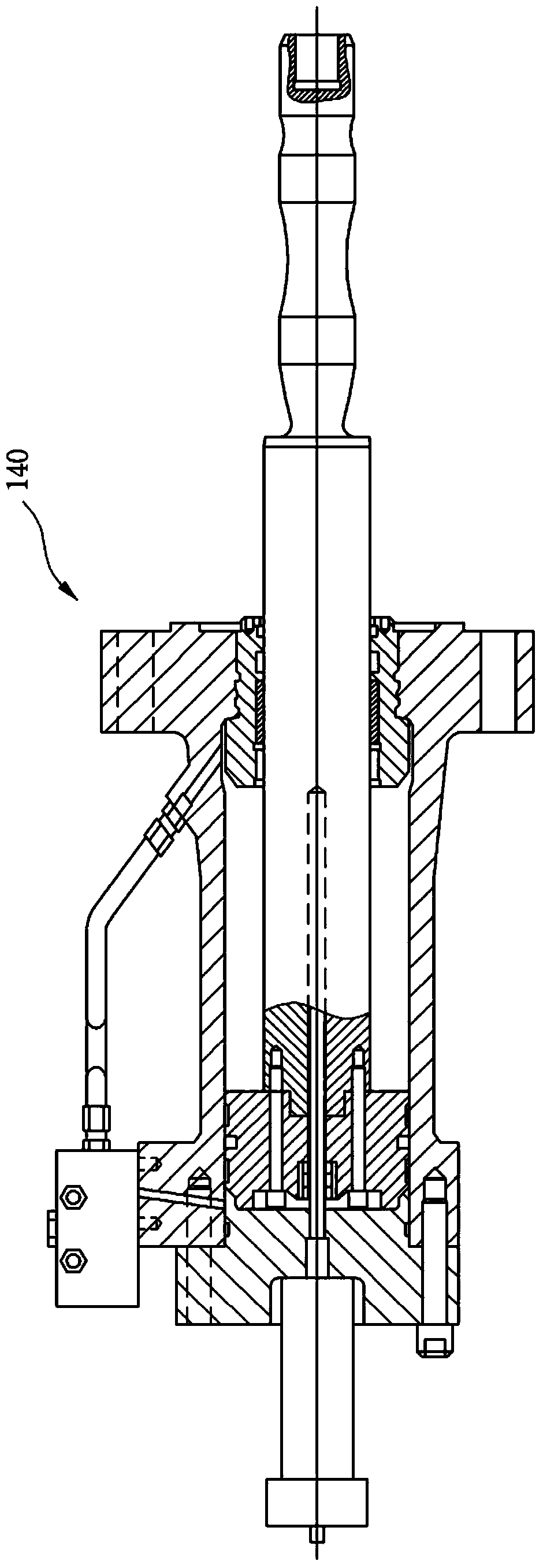

[0036] The various aspects, features and advantages of the present invention will become more apparent from the following detailed description of the preferred embodiments when taken in conjunction with the accompanying drawings. Throughout the drawings, the same reference numerals are used to designate the same or similar parts. If, in the specification, detailed descriptions of known functions or constructions will unnecessarily obscure the gist of the present invention, such detailed descriptions will be omitted.

[0037] Hereinafter, a hydraulic control device using a hydraulic actuator according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0038] figure 1 is a schematic block diagram showing a hydraulic control device using a hydraulic actuator according to the present invention. Such as figure 1 As shown, the hydraulic control device 100 includes a hydraulic actuator 110, a pressure reducing valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com