Layered honeycomb ceramic

A honeycomb ceramic and layered technology, which is applied in the field of organic waste gas treatment devices, can solve the problems that the air flow cannot be redistributed, the device cannot operate normally, and the thermal shock resistance is not good, so as to solve the problem of frequent parking and cleaning. Conducive to the release of thermal stress and the effect of improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

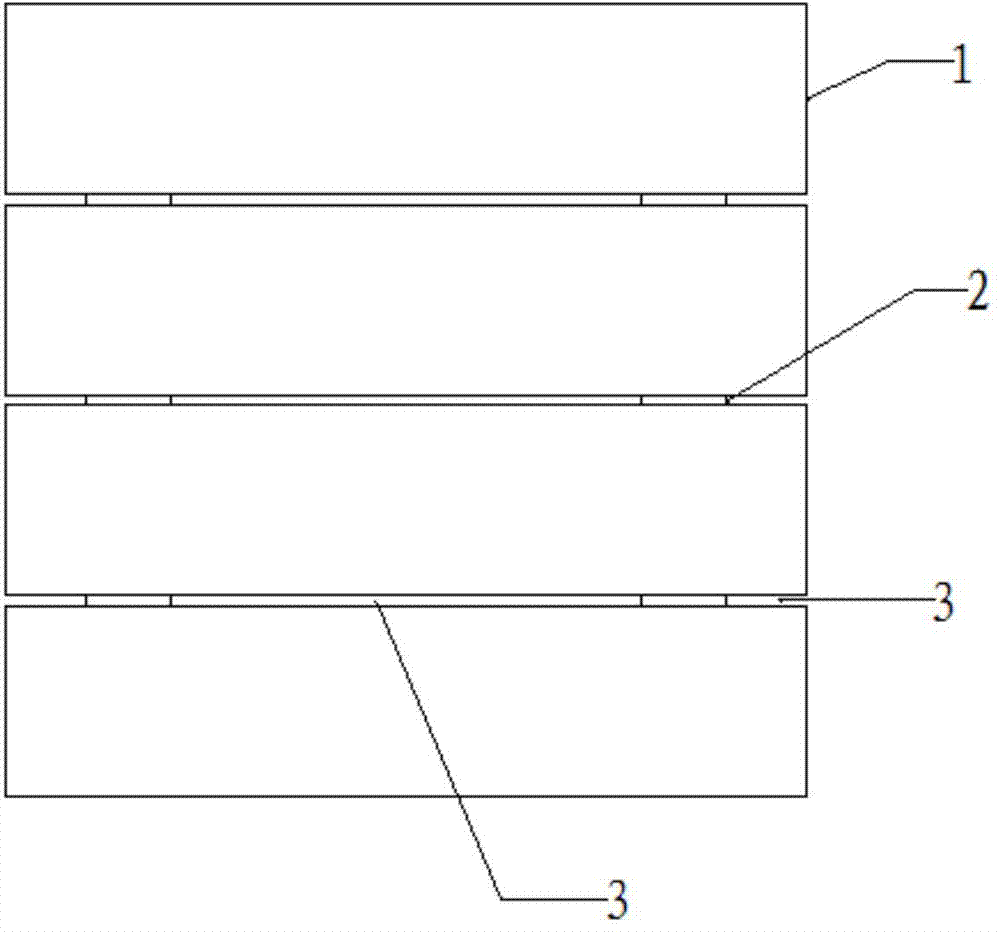

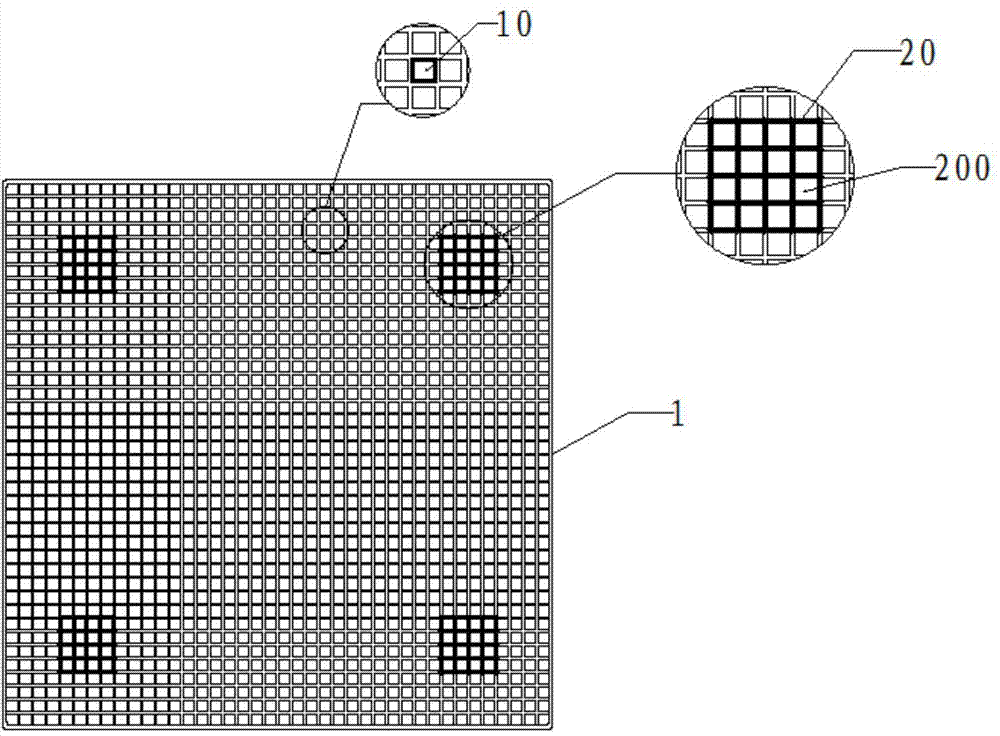

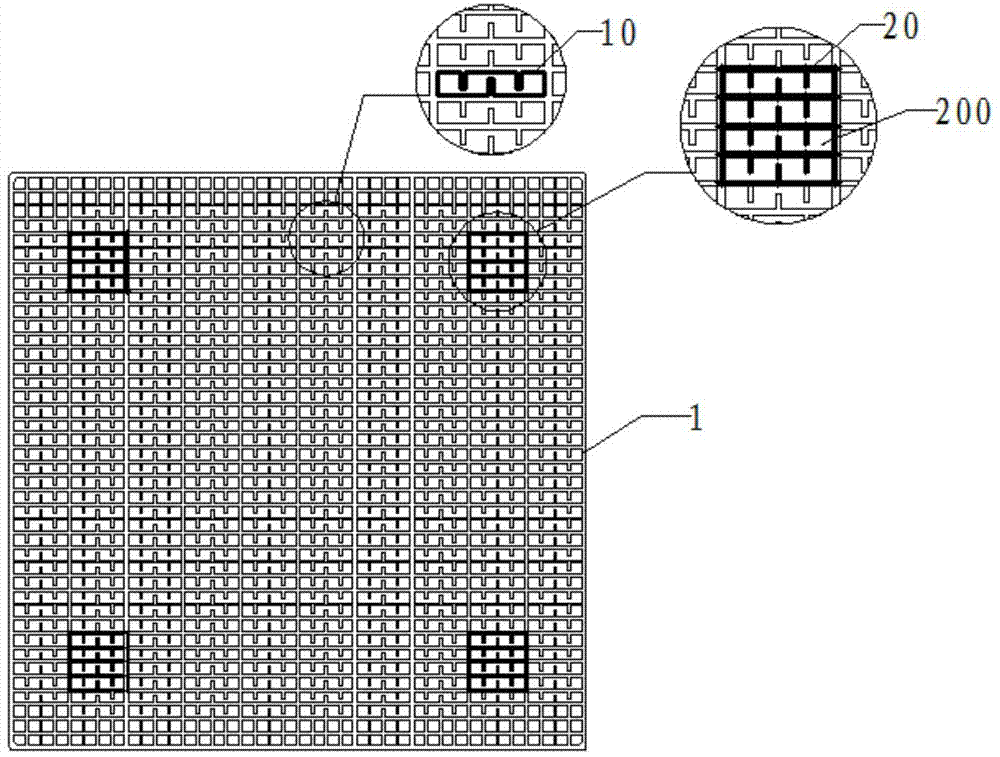

[0024] see Figure 1 to Figure 3 As shown, the layered honeycomb ceramics of this embodiment is formed by stacking more than two layers of structural units 1 and more than one layer of gasket layers 2 arranged between adjacent two layers of structural units 1 along the longitudinal direction. The structural unit 1 is distributed in a network shape with more than one gas channel A10 longitudinally penetrating the structural unit 1, the gas channels A10 on the same structural unit 1 are not connected to each other, and the gas channels A10 of the adjacent two-layer structural unit 1 One-to-one correspondence, the gasket layer 2 is composed of more than one gasket 20 distributed on this level at intervals, and the gas channels A10 of the adja...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com