Half-grouting sleeve embedded with cone

A semi-grouting sleeve and cone-shaped technology, applied in structural elements, building components, building reinforcements, etc., can solve the problems of bulky sleeve shape, time-consuming and labor-intensive processing, time-consuming and labor-intensive, etc., so as to reduce material costs and widen engineering applications. Foreground, processing and making simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

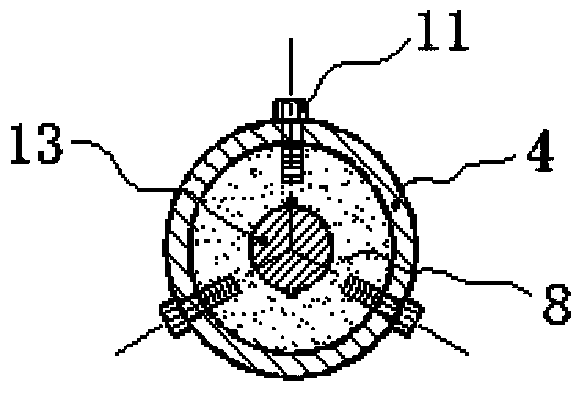

[0028] A semi-grouting sleeve embedded with a cone in the present invention, comprising: a connector 3, a sleeve body 4, a grouting opening 6, a grouting opening 7, a cone 9, a welding seam 10, a shear bolt 11, an elastic Rubber sealing ring 12. The connector 3 is provided with a connector internal thread 31 and a connector groove 32; the sleeve body 4 is embedded with a cone 9; the cone 9 is welded to the sleeve body 4 The slit 10 is fixed; the sleeve body 4 is provided with 3 rows of screw holes, the screw holes are provided with threads, the position interval of the 3 rows of screw holes is 120 degrees, and the screw holes are screwed with shear bolts 11; The sleeve body 4 is processed from high-quality carbon structural steel, low-alloy high-strength steel, and alloy structural steel

[0029] After the connecting piece is put into the sleeve body, the sleeve body is rolled to reduce the inner diameter corresponding to the concave part of the connecting piece, and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com