Pretreatment production line

A production line and pretreatment technology, applied in heat treatment equipment, quenching devices, manufacturing tools, etc., can solve problems affecting the working environment, heat treatment quality decline, personal injury, etc., to improve cooling uniformity, process flexibility, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

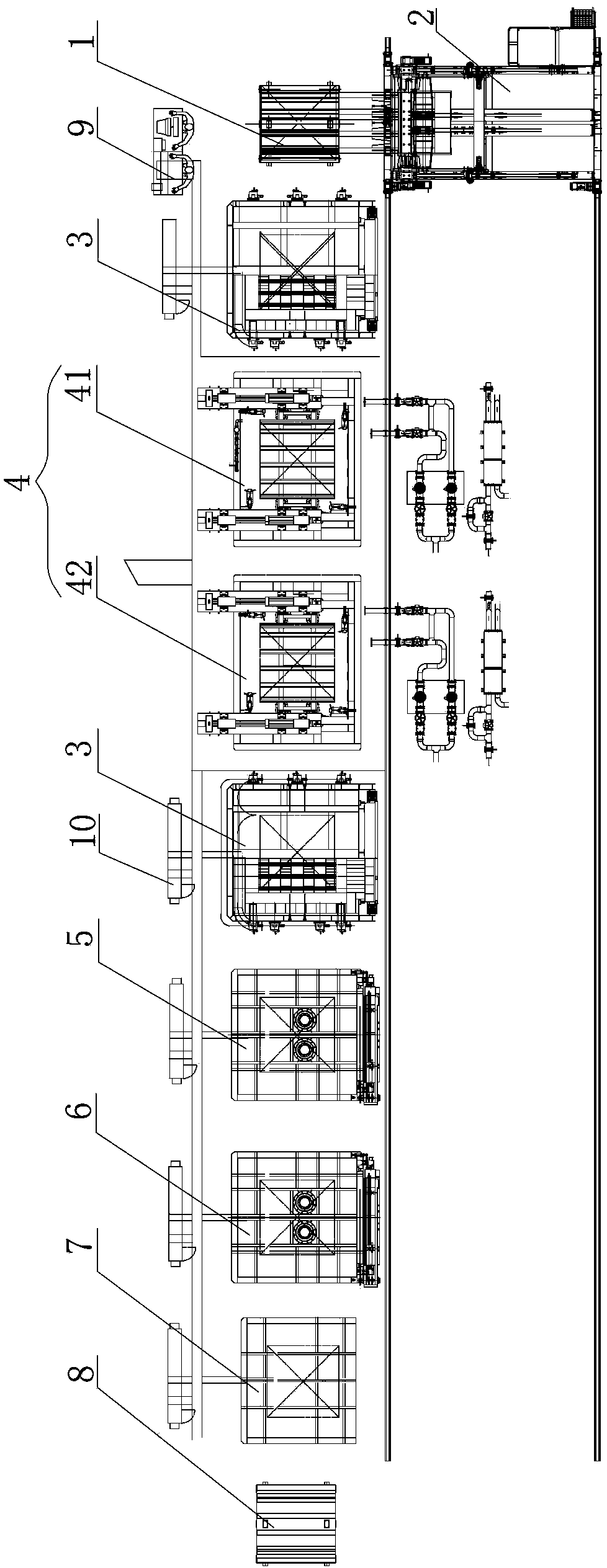

[0024] See figure 1 , the present invention sequentially includes a fixed loading table 1, a transmission device 2, a heating furnace 3, a quenching and cooling device 4, a high temperature tempering furnace 5, a low temperature tempering furnace 6, an air cooling device 7, a discharge table 8 and a host computer control system 9, and arranged in a straight line. The heating furnace 3 is an electric heating furnace or a gas heating furnace, and the number of heating furnaces 3 can be expanded as required. Workpieces can be transferred between devices by means of mobile forklifts.

[0025] The quenching and cooling equipment 4 is a quenching salt tank 41, a quenching water tank 42 and / or a quenching oil tank, and one or more quenching tanks can be set as required. When multiple quenching tanks are set, different quenching media are contained in multiple quenching tanks, and the workpieces that come out of the same heating furnace are put into quenching tanks filled with diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com