A kind of high anti-corrosion coating prepared with loaded nano-silica hyperbranched fluororesin

A technology of nano-silica and anti-corrosion coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of suboptimal corrosion resistance and difficulty in surface protection with marine engineering equipment, and achieve marine resistance Excellent climate corrosion performance, low equipment cost, easy repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

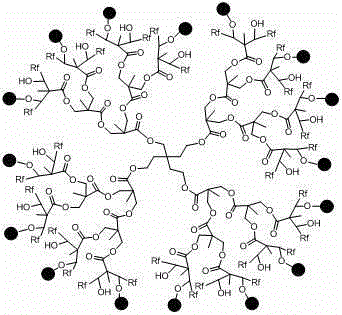

Method used

Image

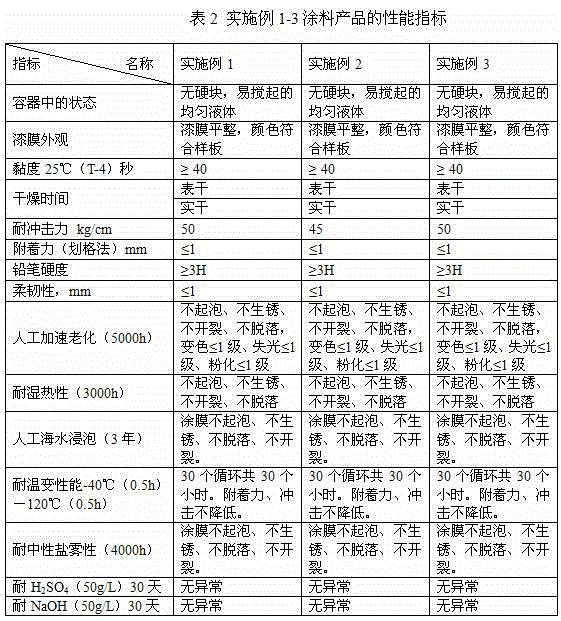

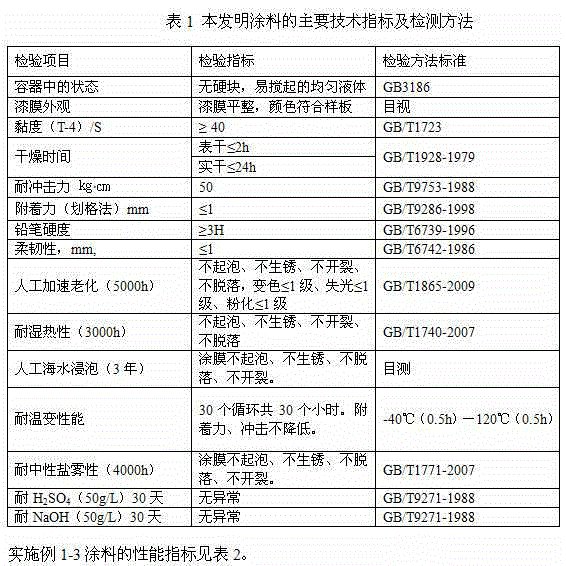

Examples

Embodiment 1

[0042] The distribution ratio of each component in this embodiment: it is formed by mixing 800kg of component A and 100kg of component B;

[0043]Composition of component A: 440kg of nano-silica-loaded hyperbranched fluororesin, BYK-1638kg of wetting and dispersing agent, 240kg of rutile titanium dioxide, mixed solvent (mixed with butyl acetate and propylene glycol methyl ether acetate, among which, The mass ratio of butyl acetate to propylene glycol methyl ether acetate is 4:1) 99.2kg, leveling agent BYK-3334kg, catalyst 1%T-120.8kg;

[0044] Composition of component B: Bayer N-7550kg, Bayer N-339050kg.

[0045] The preparation method comprises the following steps:

[0046] 1) Add 440kg of nano-silica hyperbranched fluororesin and 8kg of wetting and dispersing agent BYK-163 into the container, stir well and add 240kg of rutile titanium dioxide and butyl acetate and propylene glycol methyl ether at a mass ratio of 4:1 The mixed solvent 49.6kg of acetate is stirred evenly;

...

Embodiment 2

[0052] The distribution ratio of each component in this embodiment: it is formed by mixing 1100kg of component A and 100kg of component B;

[0053] Composition of component A: 660kg of nano-silica hyperbranched fluororesin, 22kg of wetting and dispersing agent EFKA-4050, 300.3kg of rutile titanium dioxide, a mixture of butyl acetate and propylene glycol methyl ether acetate with a mass ratio of 5:1 Solvent 114.18kg, leveling agent (a mixture of leveling agent BYK-333 and EFKA-3777 with a mass ratio of 2:1) 3.3kg, catalyst stannous octoate 0.22kg;

[0054] Composition of component B: Bayer N-3390100kg.

[0055] The preparation method comprises the following steps:

[0056] 1) Add 660kg of nano-silica loaded hyperbranched fluororesin, 22kg of wetting and dispersing agent EFKA-4050 into the container and stir evenly, then add 300.3kg of pigment and filler rutile titanium dioxide and acetic acid with a mass ratio of 5:1 57.09kg of mixed solvent of butyl ester and propylene glyco...

Embodiment 3

[0062] The distribution ratio of each component in this embodiment: it is formed by mixing 900kg of component A and 100kg of component B;

[0063] Composition of component A: 630kg of nano-silica loaded hyperbranched fluororesin, BYK-1044.5kg of wetting and dispersing agent, 180.3kg of rutile titanium dioxide, a mixture of butyl acetate and propylene glycol methyl ether acetate with a mass ratio of 2:1 Solvent 84.42kg, 0.9kg leveling agent EFKA-3777, 0.18kg catalyst 1%T-12;

[0064] Composition of component B: Bayer N-75 100kg.

[0065] The preparation method comprises the following steps:

[0066] 1) Add 630kg of nano-silica hyperbranched fluororesin and 4.5kg of wetting and dispersing agent BYK-104 into the container, stir well and add 180kg of rutile titanium dioxide and butyl acetate and propylene glycol methyl at a mass ratio of 2:1 The mixed solvent 42.21kg of ether acetate is stirred evenly;

[0067] 2) Pre-disperse the composition obtained in step 1), and grind it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com