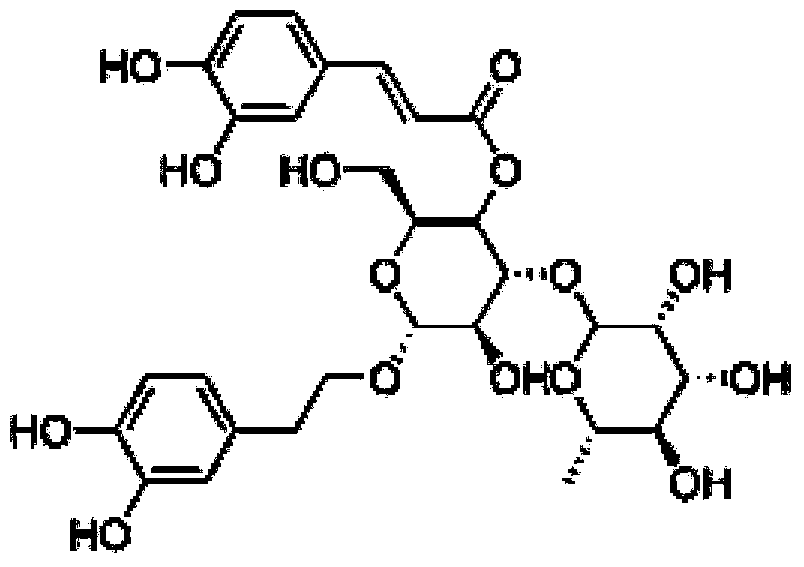

Method for separating and purifying verbascoside from desertliving cistanche

A technology for the separation and purification of verbascoside, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of high price of β-glucosidase, unsuitability for large-scale industrial production, complicated preparation process, etc., and achieve The effect of high verbascoside content, easy industrial production, and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

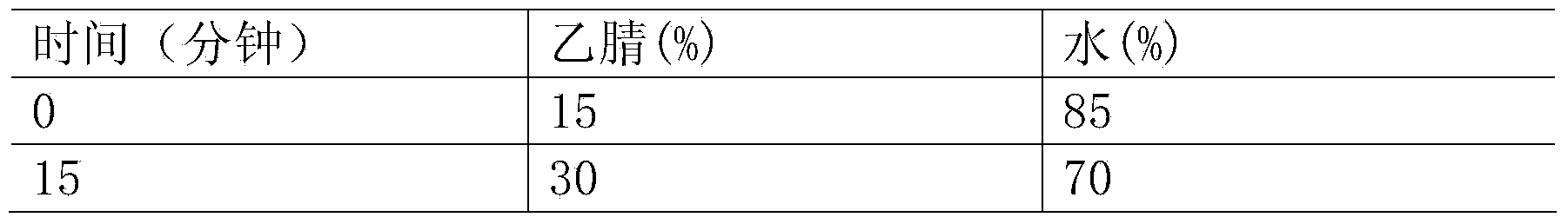

Embodiment 1

[0050] Cut 200 kg of fresh Cistanche deserticola (the dry content of verbascoside is 5.2%) into slices with a thickness of 8mm, put them into 1000 kg of boiling water, heat and reflux for extraction for 2 hours, extract twice more according to the above method, combine the water extracts three times, and put them on HPD400 Porous resin column adsorption, first washed with water to remove large polar impurities such as polysaccharides, then eluted with 40% ethanol, followed by liquid phase, combined components with high content of acteoside, concentrated and dried to obtain 3.4 kg of crude actcoside, detected by liquid chromatography The content is 62.2%.

[0051] Add 10 times water to dissolve the crude acteoside, then put it on a 100-mesh polyamide resin column for adsorption, elute with 50% ethanol, track the liquid phase, combine the eluate components with high actcoside content, concentrate and dry to obtain 1.9 kg of actcoside , the content detected by liquid chromatograp...

Embodiment 2

[0053] Slice 200 kg of fresh Cistanche deserticola (the dry content of verbascoside is 5.2%) with a thickness of 3mm, put it into the extraction tank, steam it from the bottom of the tank for 30 minutes, add 800 kg of 95% ethanol, and ultrasonically extract for 1.5 hours. Extract three times, combine the extracts three times, concentrate under reduced pressure until there is no ethanol smell, add 1000 kg of water, filter, and absorb on HPD200A macroporous resin column, first wash with water to remove impurities, then elute with 30% ethanol, liquid phase tracking and merge verbascoside The eluted fraction with high content was concentrated and dried to obtain 3.2 kg of crude verbascoside, and the liquid phase detection content was 68.6%.

[0054] The crude acteoside was dissolved in 12 times of water, then adsorbed on polyamide resin, eluted with 45% ethanol, tracked in liquid phase, combined components with high content were concentrated and dried under reduced pressure to obtain...

Embodiment 3

[0056] Slice 200 kg of fresh Cistanche deserticola (the dry content of verbascoside is 5.2%), with a thickness of 2mm, put it into the extraction tank, steam it with saturated steam, add 1000 kg of 80% ethanol, reflux extraction for 2 hours, extract three times, and combine the extracts Concentrate under reduced pressure until there is no ethanol smell, add 800 kg of water to filter, and absorb the polyamide resin on the filtrate, first wash off impurities with water, then elute with 50% ethanol, track the liquid phase, combine components with high verbascoside content, and concentrate under reduced pressure Dried to obtain 3.5 kg of crude verbascoside, the liquid phase detection content was 61.8%.

[0057] The crude acteoside was dissolved in 12 times of water, then adsorbed on the AB-8 macroporous resin column, eluted with 40% ethanol, combined with the eluted components with high acteoside content, concentrated and dried under reduced pressure to obtain 1.9 kg of acteoside, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com