A kind of method utilizing dual catalyst heterogeneous activation persulfate to treat organic waste water

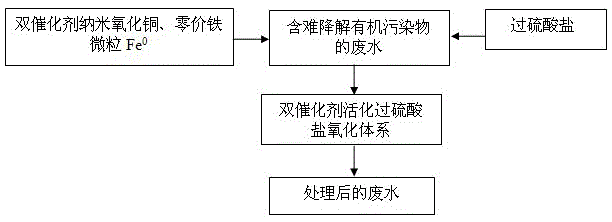

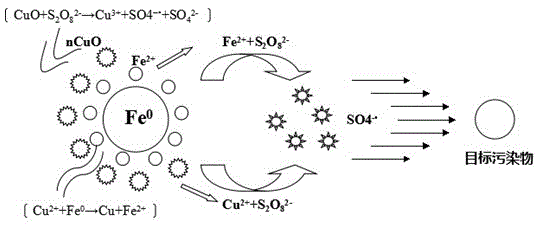

A technology for activating persulfate and organic wastewater, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of a large amount of iron sludge and low effective utilization rate of persulfate, achieve high utilization rate, avoid large-scale production and subsequent treatment, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

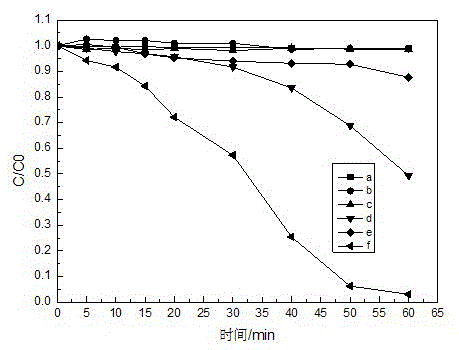

[0048] This example compares the color of dye wastewater under four methods: single use of persulfate, single catalyst, single use of zero-valent iron to activate persulfate, single use of nano-copper oxide to activate persulfate, and use of dual catalysts to activate persulfate. Degree removal rate and CODcr removal rate.

[0049] The specific operation steps are as follows:

[0050] (1) According to figure 1 In the process sequence shown, the dye wastewater is taken, and the CODcr of the wastewater measured is 300mg / L, and the pH is 6.8. A 250mL Erlenmeyer flask was used as the reactor, and 200mL of waste water was added.

[0051] (2) Add dual catalysts into the above-mentioned Erlenmeyer flask reactor, and the preparation method of the dual catalysts is as follows: uniformly mix nano-copper oxide particles and zero-valent iron particles in a mass ratio of 1:2.

[0052] (3) The dosage of nano-copper oxide in the catalyst is 0.05g / L, and the dosage of zero-valent iron part...

Embodiment 2

[0064] A method for treating organic wastewater by utilizing dual-catalyst heterogeneously and efficiently activating persulfate, the specific operation steps are as follows:

[0065] (1) Take the dye wastewater, the CODcr of the wastewater is 300mg / L, and the pH is 6.8. A 250mL Erlenmeyer flask was used as the reactor, and 200mL of waste water was added. Adjust the pH value to 3, 5, 7, 9 respectively.

[0066] (2) A catalyst is added to the above-mentioned Erlenmeyer flask reactor, and the dosage of nano-copper oxide in the catalyst is 0.05g / L, and the dosage of zero-valent iron particles is 0.1g / L.

[0067] (3) Add 238 mg / L of sodium persulfate to the reactor in step (2) and react at room temperature for 1 hour.

[0068] Its result is as shown in table 2, and the result of table 2 shows, the method that double catalyst activated persulfate heterogeneously degrades organic waste water that the present invention establishes all can have comparatively good effect to printing ...

Embodiment 3

[0073] A method for treating organic wastewater by utilizing dual-catalyst heterogeneously and efficiently activating persulfate, the specific operation steps are as follows:

[0074] (1) Take the dye wastewater, the CODcr of the wastewater is 300mg / L, and the pH is 6.8. A 250mL Erlenmeyer flask was used as the reactor, and 200mL of waste water was added.

[0075] (2) A catalyst is added to the above-mentioned Erlenmeyer flask reactor, and the dosage of nano-copper oxide in the catalyst is 0.05g / L, and the dosage of zero-valent iron particles is 0.1g / L.

[0076] (3) Add 238 mg / L of sodium persulfate to the reactor in step (2) and react at room temperature for 1 hour.

[0077] The results are shown in Table 3, and the results in Table 3 show that the dual-catalyst activated persulfate heterogeneously degraded organic wastewater method established by the present invention ensures the persistence and high efficiency of the persulfate method.

[0078] Table 3 Two kinds of persul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com