Method for treating organic wastewater by using double catalysts to heterogeneously activate persulfates

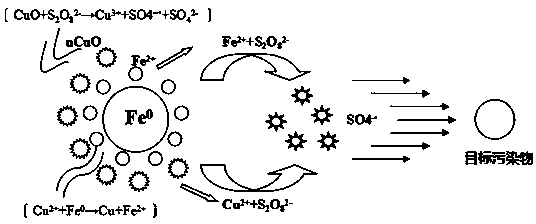

A technology for activating persulfate and organic wastewater, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of large amount of iron sludge and low effective utilization rate of persulfate, achieve high utilization rate, avoid mass production and subsequent treatment, Easy to recycle and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

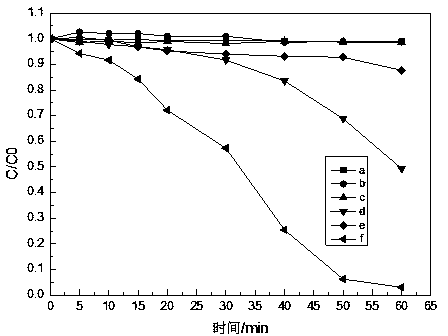

[0048] This example compares the color of dye wastewater under four methods: single use of persulfate, single catalyst, single use of zero-valent iron to activate persulfate, single use of nano-copper oxide to activate persulfate, and use of dual catalysts to activate persulfate. Degree removal rate and CODcr removal rate.

[0049] The specific operation steps are as follows:

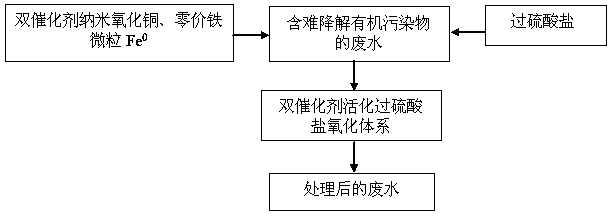

[0050] (1) According to figure 1 In the process sequence shown, the dye wastewater is taken, and the CODcr of the wastewater measured is 300mg / L, and the pH is 6.8. A 250mL Erlenmeyer flask was used as the reactor, and 200mL of waste water was added.

[0051] (2) Add dual catalysts into the above-mentioned Erlenmeyer flask reactor, and the preparation method of the dual catalysts is as follows: uniformly mix nano-copper oxide particles and zero-valent iron particles in a mass ratio of 1:2.

[0052] (3) The dosage of nano-copper oxide in the catalyst is 0.05g / L, and the dosage of zero-valent iron part...

Embodiment 2

[0064] A method for treating organic wastewater by utilizing dual-catalyst heterogeneously and efficiently activating persulfate, the specific operation steps are as follows:

[0065] (1) Take the dye wastewater, the CODcr of the wastewater is 300mg / L, and the pH is 6.8. A 250mL Erlenmeyer flask was used as the reactor, and 200mL of waste water was added. Adjust the pH value to 3, 5, 7, 9 respectively.

[0066] (2) A catalyst is added to the above-mentioned Erlenmeyer flask reactor, and the dosage of nano-copper oxide in the catalyst is 0.05g / L, and the dosage of zero-valent iron particles is 0.1g / L.

[0067] (3) Add 238 mg / L of sodium persulfate to the reactor in step (2) and react at room temperature for 1 hour.

[0068] Its result is as shown in table 2, and the result of table 2 shows, the method that double catalyst activated persulfate heterogeneously degrades organic waste water that the present invention establishes all can have comparatively good effect to printing ...

Embodiment 3

[0073] A method for treating organic wastewater by utilizing dual-catalyst heterogeneously and efficiently activating persulfate, the specific operation steps are as follows:

[0074] (1) Take the dye wastewater, the CODcr of the wastewater is 300mg / L, and the pH is 6.8. A 250mL Erlenmeyer flask was used as the reactor, and 200mL of waste water was added.

[0075] (2) A catalyst is added to the above-mentioned Erlenmeyer flask reactor, and the dosage of nano-copper oxide in the catalyst is 0.05g / L, and the dosage of zero-valent iron particles is 0.1g / L.

[0076] (3) Add 238 mg / L of sodium persulfate to the reactor in step (2) and react at room temperature for 1 hour.

[0077] The results are shown in Table 3, and the results in Table 3 show that the dual-catalyst activated persulfate heterogeneously degraded organic wastewater method established by the present invention ensures the persistence and high efficiency of the persulfate method.

[0078] Table 3 Two kinds of persul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com