ZnGa2O4-Ga2O3 heterojunction photocatalytic material, preparation method and application of material

A photocatalytic material and heterojunction technology, applied in chemical instruments and methods, hydrocarbon production from carbon oxides, physical/chemical process catalysts, etc., can solve problems such as preparation difficulties, and achieve selective and excellent photocatalytic degradation Organic pollutants, the effect of improving the efficiency of photocatalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

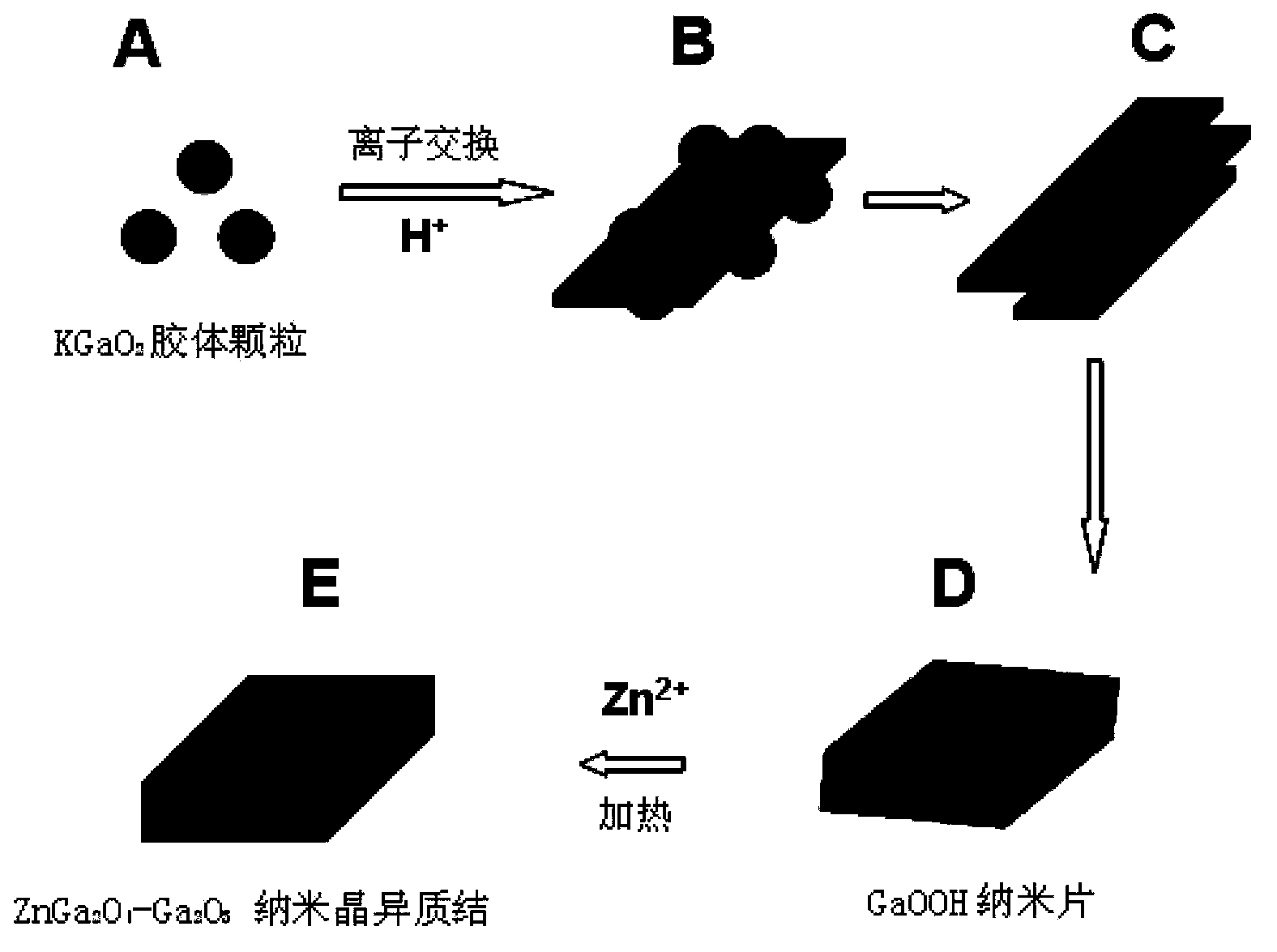

[0039] Embodiment 1 Flaky ZnGa 2 o 4 -Ga 2 o 3 Preparation of heterojunction

[0040] In a typical synthesized flake ZnGa 2 o 4 -Ga 2 o 3 During the heterojunction process, weigh 0.494g of sodium gallate powder and dissolve it in 40mL of deionized water, weigh 0.120g of acetic acid, dissolve it in 40mL of deionized water, then pour 40mL of acetic acid solution into 40mL of sodium gallate solution, After the mixed solution was stirred and reacted by magnetic force at room temperature for 8 hours, it was centrifuged and dried to obtain gallium oxyhydroxide nanosheets. Gallium oxyhydroxide nanosheets have a thickness of about 20nm and a length of about 200nm.

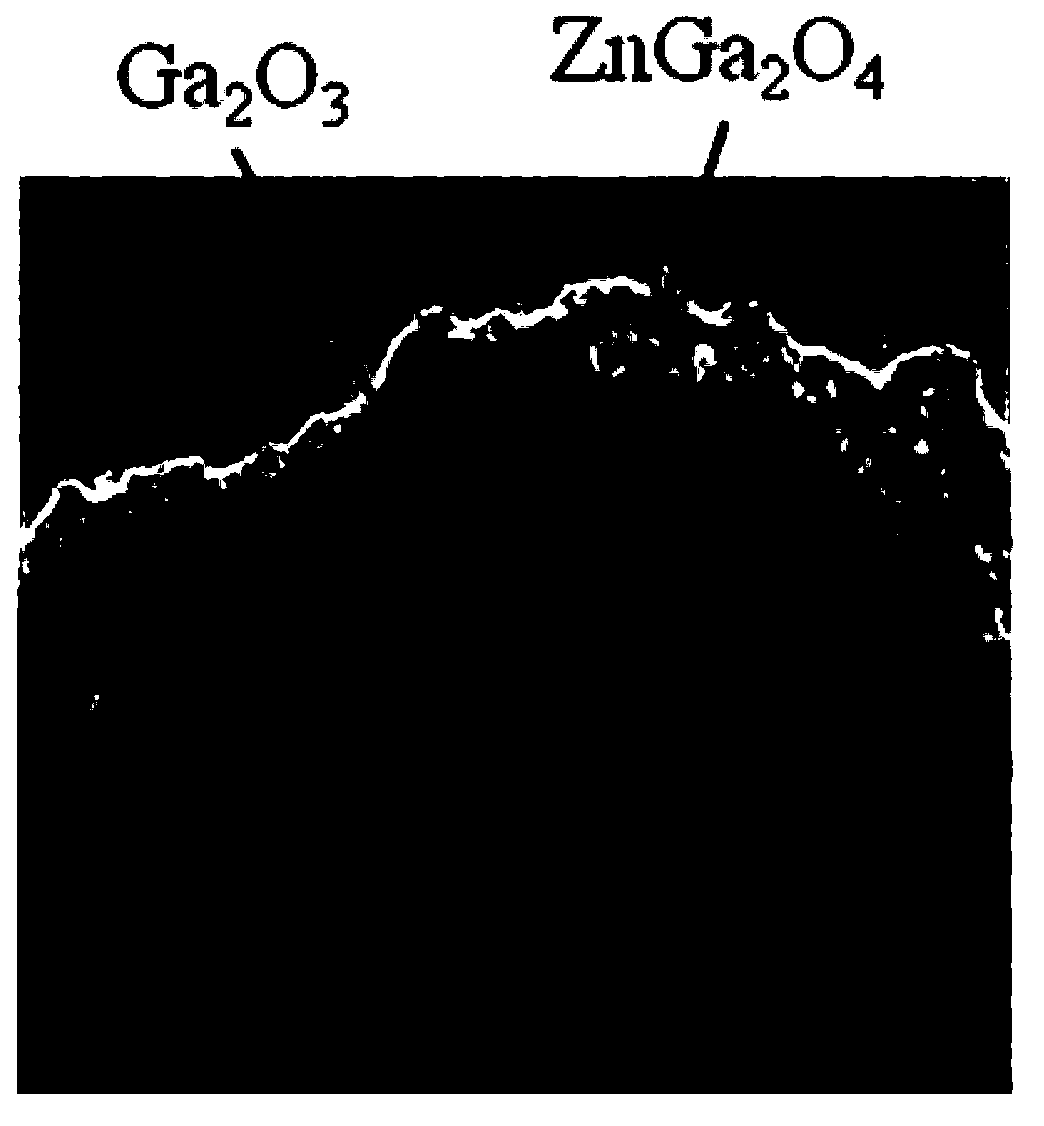

[0041] Weigh 0.203g of prepared gallium oxyhydroxide nanosheets, and 0.008g Zn(CH 3 COO) 2 Mix, add 5mL ethanol, grind in an agate mortar for 20min, mix well, dry at 60°C for 3h, and then calcinate in a muffle furnace at 800°C for 5h to obtain flaky ZnGa with mesoporous exposed (200) planes 2 o 4 -Ga 2 o 3 Na...

Embodiment 2

[0044] Embodiment 2 Flaky ZnGa 2 o 4 -Ga 2 o 3 Preparation of heterojunction

[0045] In a typical synthesized flake ZnGa 2 o 4 -Ga 2 o 3 During the heterojunction process, weigh 0.494g of sodium gallate powder and dissolve it in 40mL of deionized water, weigh 0.120g of acetic acid, dissolve it in 40mL of deionized water, then pour 40mL of acetic acid solution into 40mL of sodium gallate solution, After the mixed solution was stirred and reacted by magnetic force at room temperature for 5 hours, it was centrifuged and dried to obtain gallium oxyhydroxide nanosheets. Gallium oxyhydroxide nanosheets have a thickness of about 20nm and a length of about 200nm.

[0046] Weigh 0.203g of prepared gallium oxyhydroxide nanosheets, and 0.004g Zn(CH 3 COO) 2 Mix, add 10mL ethanol, fully grind in an agate mortar for 30min, mix well, dry at 80°C for 2h, and then calcinate in a muffle furnace at 1000°C for 10h to obtain a sheet with mesoporous exposed (200) plane ZnGa 2 o 4 Ga ...

Embodiment 3

[0047] Example 3 Flake ZnGa 2 o 4 -Ga 2 o 3 Preparation of heterojunction

[0048] In typical synthetic flake Ga 2 o 3 -ZnGa 2 o 4 During the heterojunction process, weigh 0.494g of sodium gallate powder and dissolve it in 40mL of deionized water, weigh 0.240g of acetic acid, dissolve it in 40mL of deionized water, then pour 40mL of acetic acid solution into 40mL of sodium gallate solution, The mixed solution was subjected to magnetic stirring reaction at room temperature for 10 h, then centrifuged and dried to obtain gallium oxyhydroxide nanosheets. Gallium oxyhydroxide nanosheets have a thickness of about 20nm and a length of about 150nm.

[0049] Weigh 0.203g of prepared gallium oxyhydroxide nanosheets, and 0.016g Zn(CH 3 COO) 2 Mix, add 5mL of ethanol, grind in an agate mortar for 20min, mix thoroughly, dry at 70°C for 2.5h, and calcinate in a muffle furnace at 900°C for 7h to obtain flaky ZnGa with mesoporous exposed (200) planes 2 o 4 -Ga 2 o 3 Nanocrystall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com