Fluorescent-powder setting method and manufacturing method of light-emitting diode

A technology of phosphor powder and light-emitting layer, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven mixing and distribution of blue and yellow light, affecting the normal use of light-emitting diodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] See Figure 1-5 , Shows a phosphor setting method of an embodiment of the present invention. The method mainly includes the following steps:

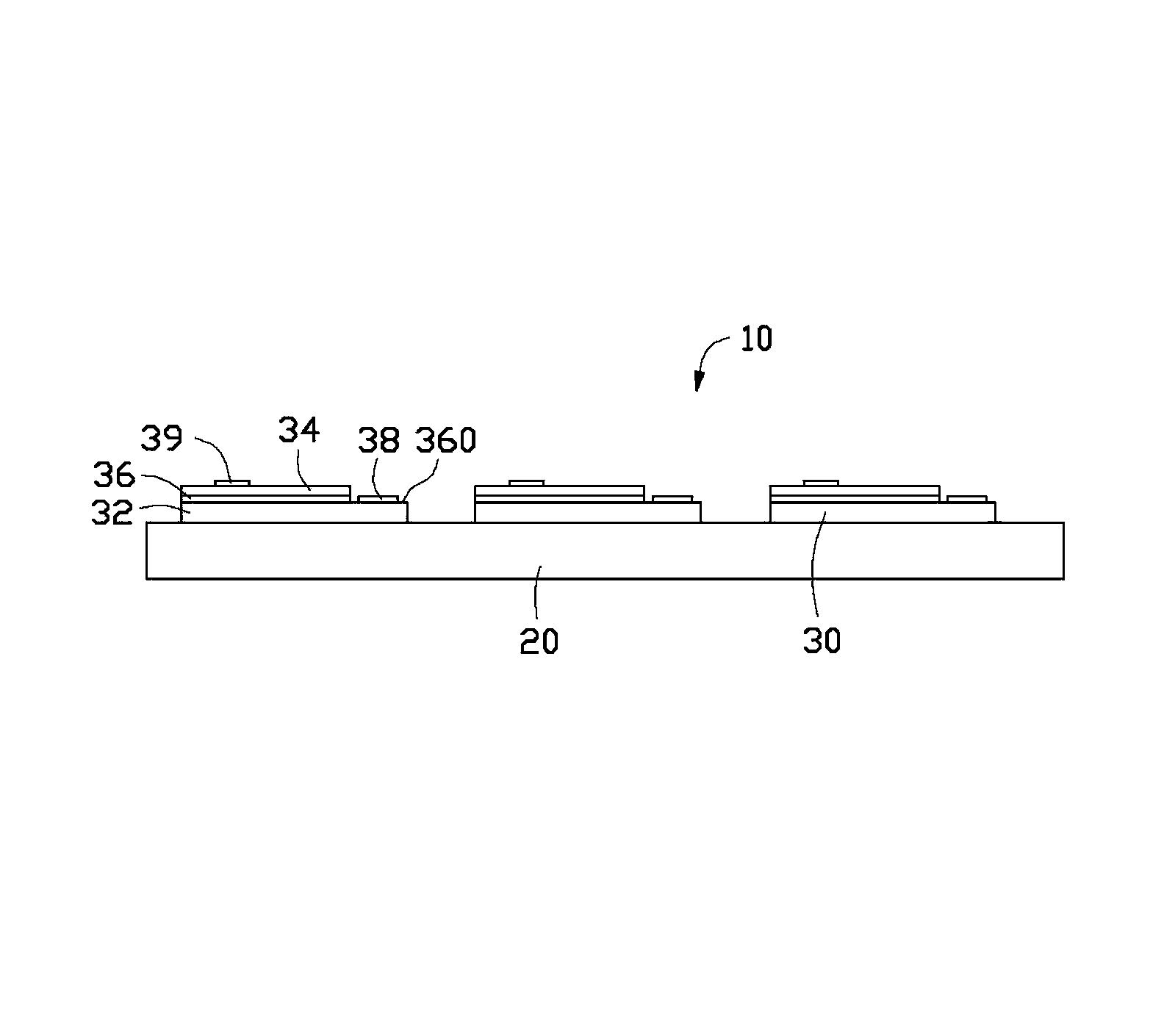

[0020] First, like figure 1 As shown, a wafer 10 is provided. The wafer 10 includes a substrate 20 and a plurality of epitaxial structures 30 formed on the top surface of the substrate 20. The substrate 20 can be made of sapphire, silicon carbide and other materials, and is used to provide a supporting environment for the growth of the epitaxial structure 30. Each epitaxial structure 30 includes a first semiconductor layer 32, a second semiconductor layer 34, a light-emitting layer 36, a first electrode 38, and a second electrode 39. In this embodiment, the first semiconductor layer 32 is an N-type gallium nitride layer, the second semiconductor layer 34 is a P-type gallium nitride layer, and the light-emitting layer 36 is a multiple quantum well gallium nitride layer. The light-emitting layer 36 can be excited by the current to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com