Structure with realization of 3D interlayer vertical interconnection by using flexible substrate and manufacturing method thereof

A technology that uses flexible and vertical interconnection, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as increased BGA crosstalk, increased return loss, and restrictions on high-frequency signal transmission , to achieve the effect of improving shielding performance, reducing attenuation amplitude and increasing transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

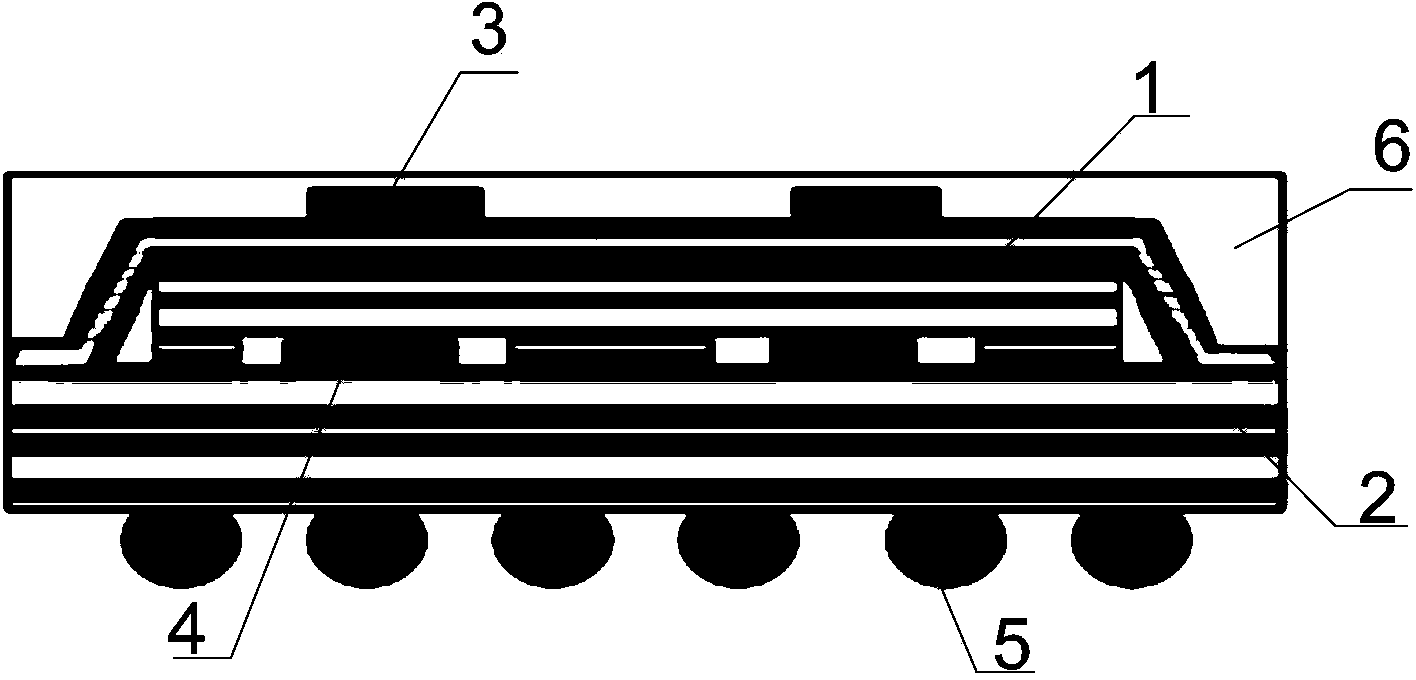

[0016] see figure 1 , this embodiment provides a structure using a flexible substrate to realize vertical interconnection between three-dimensional layers, including a first printed circuit board 1, a second printed circuit board 2, a first device 3 (such as a radio frequency component), a second Two devices 4 (such as radio frequency components), solder balls 5 and plastic sealing layer 6 . The first printed circuit board 1 is a flexible printed circuit board or a rigid-flexible printed circuit board, wherein the flexible part of the rigid-flexible printed circuit board is arranged at the upper, lower or middle position of the rigid part (this In the embodiment, a rigid-flex printed circuit board is selected, and the flexible part is arranged directly above the rigid part, and the length of the flexible part is greater than the length of the rigid part). The rigid part of the rigid-flexible printed circuit board has a certain thickness, which allows subsequent opening of gro...

Embodiment 2

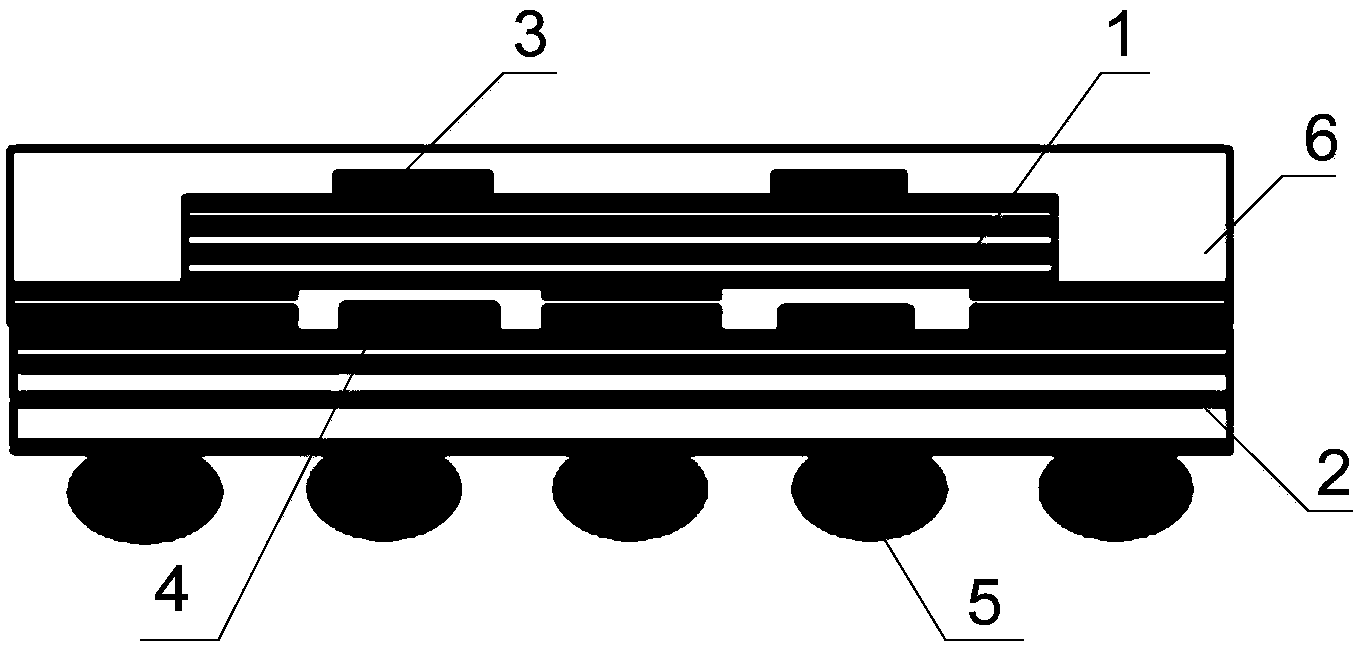

[0025] see figure 2, this embodiment provides a structure using a flexible substrate to realize vertical interconnection between three-dimensional layers, including a first printed circuit board 1, a second printed circuit board 2, a first device 3 (such as a radio frequency component), a second Two devices 4 (such as radio frequency components), solder balls 5 and plastic sealing layer 6 . The first printed circuit board 1 is a flexible printed circuit board or a rigid-flexible printed circuit board, wherein the flexible part of the rigid-flexible printed circuit board is arranged at the upper, lower or middle position of the rigid part (this In the embodiment, a rigid-flex printed circuit board is selected, and the flexible part is arranged directly below the rigid part, and the length of the flexible part is equal to the length of the rigid part). The rigid part of the rigid-flexible printed circuit board has a certain thickness, which allows subsequent opening of grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com