Repairing method of 2Cr12NiMo1W1V blade surface Al coating

A repair method and blade technology, applied in the direction of coating, metal material coating process, improvement of process efficiency, etc., can solve the problems of incomplete Al coating, fluid medium corrosion, blade size out of tolerance, etc., to achieve convenient operation, The effect of good use effect and broad application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Wash and dry the 2Cr12NiMo1W1V blades to be repaired;

[0031] (2) Use chemical methods to remove the original coating: heat the coating removal bath with a concentration of 90g / l to 80°C, and place the 2Cr12NiMo1W1V blades sprayed with Al coating to be treated in the coating removal bath to stand still 60min;

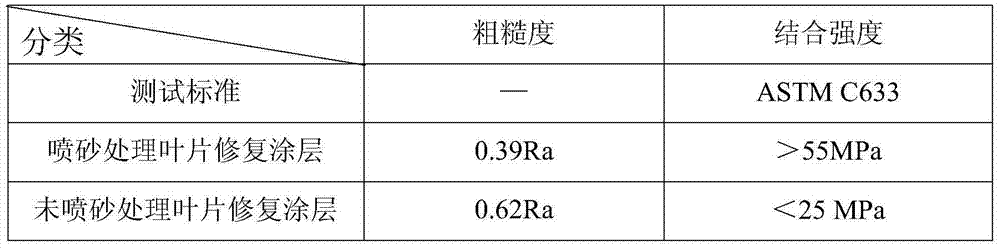

[0032] (3) Take out the treated blades, rinse the remaining tank liquid with tap water, and use 180# white corundum sand to blast the surface of the blades until the blade surface shows a metallic luster and there is no visible coating residue.

[0033] (4) Use visual inspection combined with magnetic particle inspection to inspect blades for defects.

[0034] (5) Preparation of new coating: A new coating is prepared on the surface of the blade by manual spraying, and the prepared blade is placed in a heat treatment furnace at 360°C for 60 minutes.

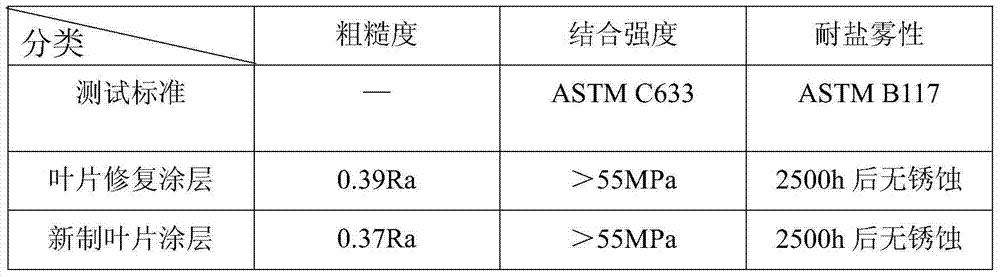

[0035] In order to compare the difference between the performance of the 2Cr12NiMo1W1V blade surface repair Al coating...

Embodiment 2

[0044] (1) Wash and dry the 2Cr12NiMo1W1V blades to be repaired;

[0045] (2) Use chemical methods to remove the original coating: heat the coating removal bath with a concentration of 80g / l to 70℃, and place the 2Cr12NiMo1W1V blades sprayed with Al coating to be processed in the coating removal bath to stand still 80min;

[0046] (3) Take out the treated blade, rinse the remaining tank liquid with tap water, and use 150# white corundum sand to sandblast the surface of the blade until the surface of the blade is metallic and there is no visible coating residue.

[0047] (4) Use visual inspection combined with magnetic particle inspection to inspect blades for defects.

[0048] (5) Preparation of new coating: Prepare a new coating on the surface of the blade by manual spraying, and place the coated blade in a heat treatment furnace at 400°C for 50 minutes.

Embodiment 3

[0050] (1) Wash and dry the 2Cr12NiMo1W1V blades to be repaired;

[0051] (2) Use chemical methods to remove the original coating: heat the coating removal bath with a concentration of 100g / l to 90°C, and place the 2Cr12NiMo1W1V blades sprayed with Al coating to be treated in the coating removal bath to stand still 50min;

[0052] (3) Take out the treated blade, rinse the remaining tank liquid with tap water, and use 120# white corundum sand to sandblast the surface of the blade until the surface of the blade shows a metallic luster and there is no visible coating residue.

[0053] (4) Use visual inspection combined with magnetic particle inspection to inspect blades for defects.

[0054] (5) Preparation of new coating: Prepare a new coating on the surface of the blade by manual spraying, and place the coated blade in a heat treatment furnace at 300°C for 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com