Method for preparing regenerated neodymium iron boron magnetic powder by using neodymium iron boron oily sludge

A technology of NdFeB and oil sludge, which is applied in the field of NdFeB oil sludge recovery and reuse, can solve the problem of high cost and achieve the effect of short recovery path, simple operation and low recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

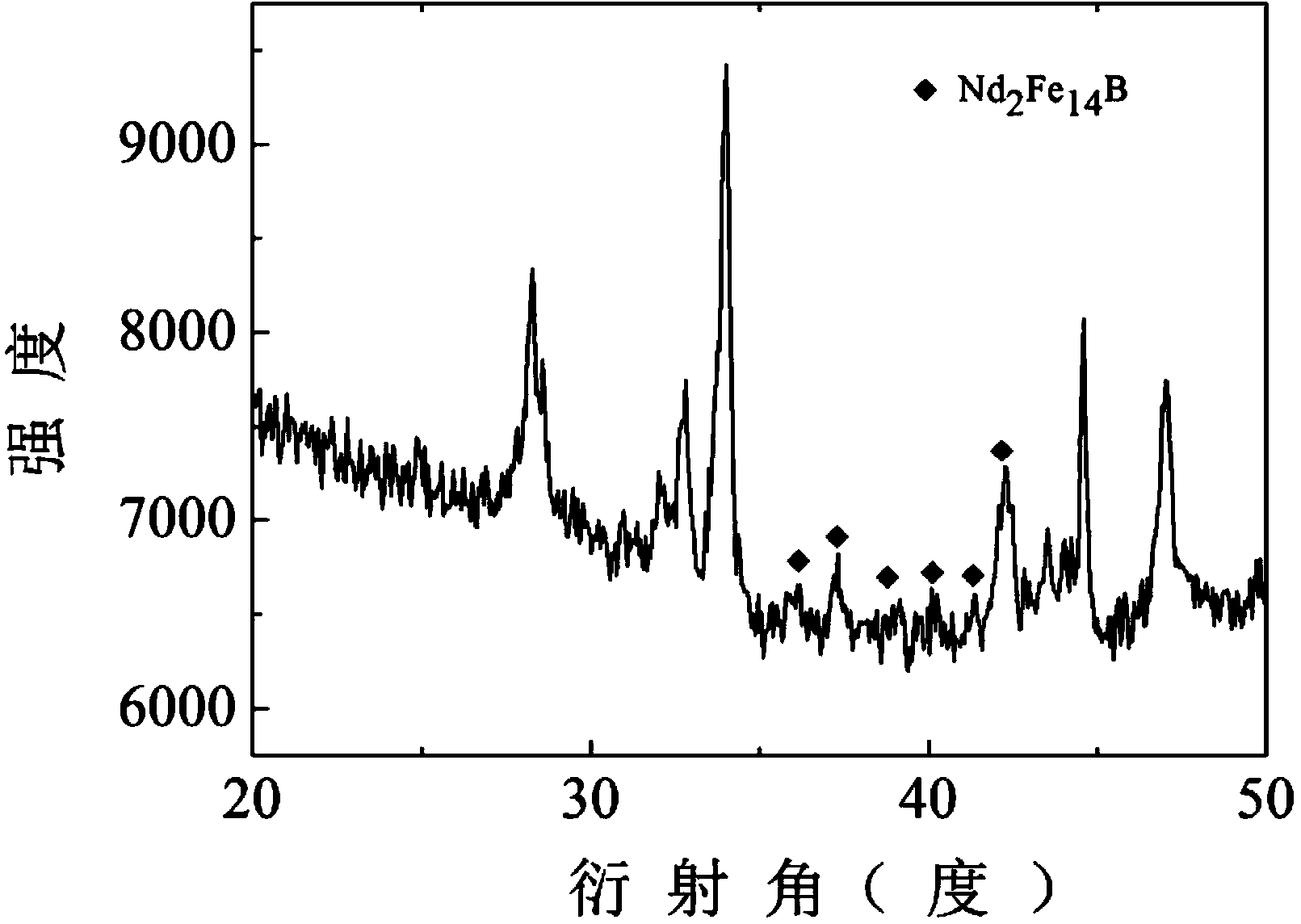

Embodiment 1

[0047] (1) Weigh 20g of NdFeB sludge and add 50ml of water to dissolve it in a beaker;

[0048] (2) Add the mixed liquid to the rotating bottle and fix it on the right end of the rotating shaft;

[0049] (3) Close the vacuum valve, vacuum, and keep the pressure inside the tube at 0.01MPa;

[0050] (4) Set the temperature to 50°C, the rotation speed to 10rpm, adjust the height of the rotating bottle, turn on the heating button and the rotating button of the rotary evaporator, and start the water bath heating;

[0051] (5) Take out the remainder after the water has evaporated.

[0052] (6) Put the remainder in a beaker, add an appropriate amount of 4mol / L hydrochloric acid, add excess hydrogen peroxide to stir after dissolution, and remove non-metal elements such as B after filtration;

[0053] (7) Adjust the pH of the solution to 8 by adding ammonia with a volume ratio of 1:1, and let it stand for 1 hour;

[0054] (8) After centrifugation, dry the precipitate and place it in a box furnace ...

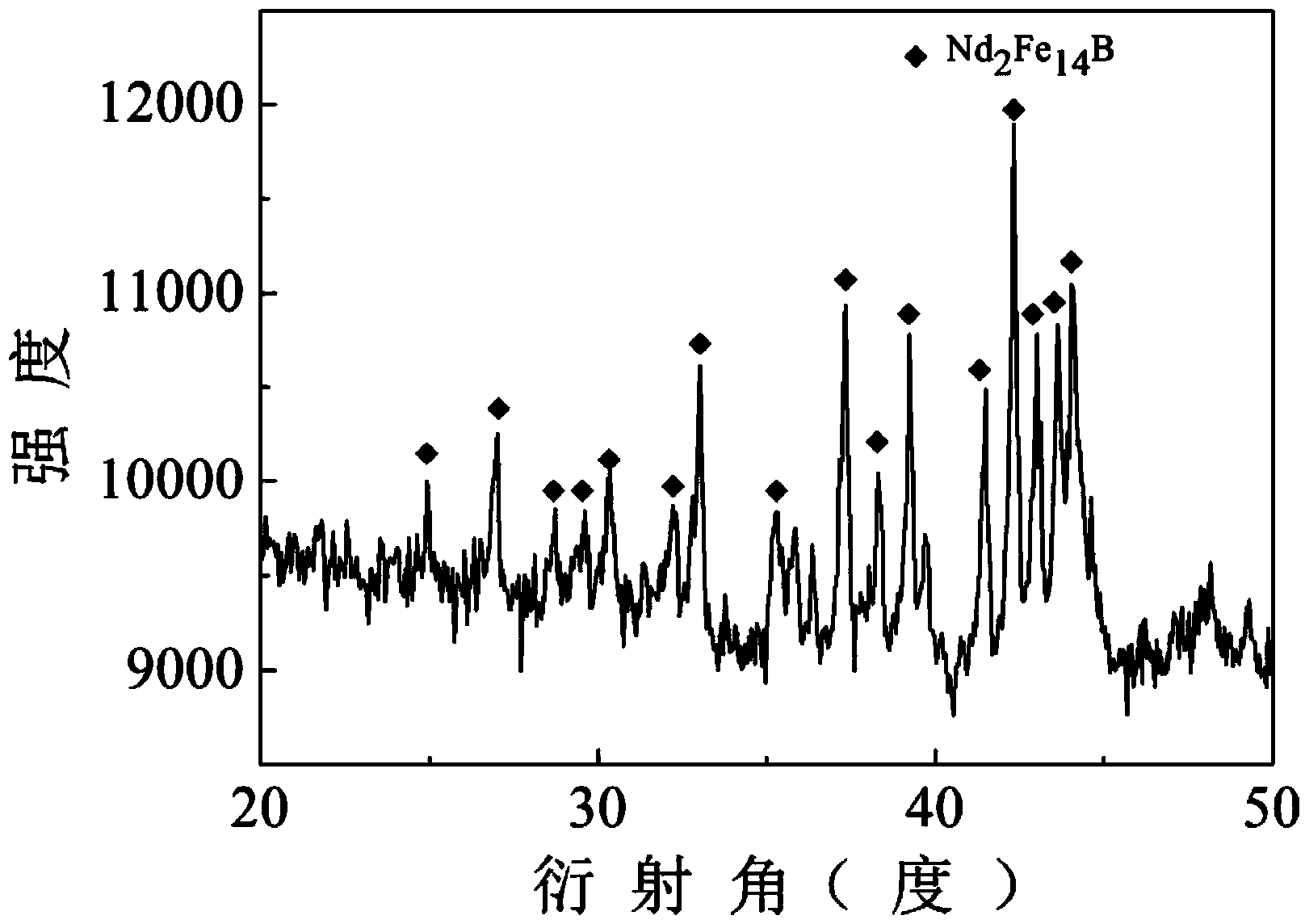

Embodiment 2

[0063] (1) Weigh 20g of NdFeB sludge and add 50ml of water to dissolve it in a beaker;

[0064] (2) Add the mixed liquid to the rotating bottle and fix it on the right end of the rotating shaft;

[0065] (3) Close the vacuum valve, vacuumize, and keep the pressure in the tube at 0.08MPa;

[0066] (4) Set the temperature to 70°C, the rotation speed to 100rpm, adjust the height of the rotating bottle, turn on the heating button and the rotating button of the rotary evaporator, and start the water bath heating;

[0067] (5) Take out the remainder after the water has evaporated.

[0068] (6) Put the remainder in a beaker, add an appropriate amount of 4mol / L hydrochloric acid, add excess hydrogen peroxide to stir after dissolution, and remove non-metal elements such as B after filtration;

[0069] (7) Adjust the pH of the solution to 9 by adding ammonia with a volume ratio of 1:1, and let it stand for 1.5;

[0070] (8) After centrifugation, the precipitate is dried and placed in a box furnace ...

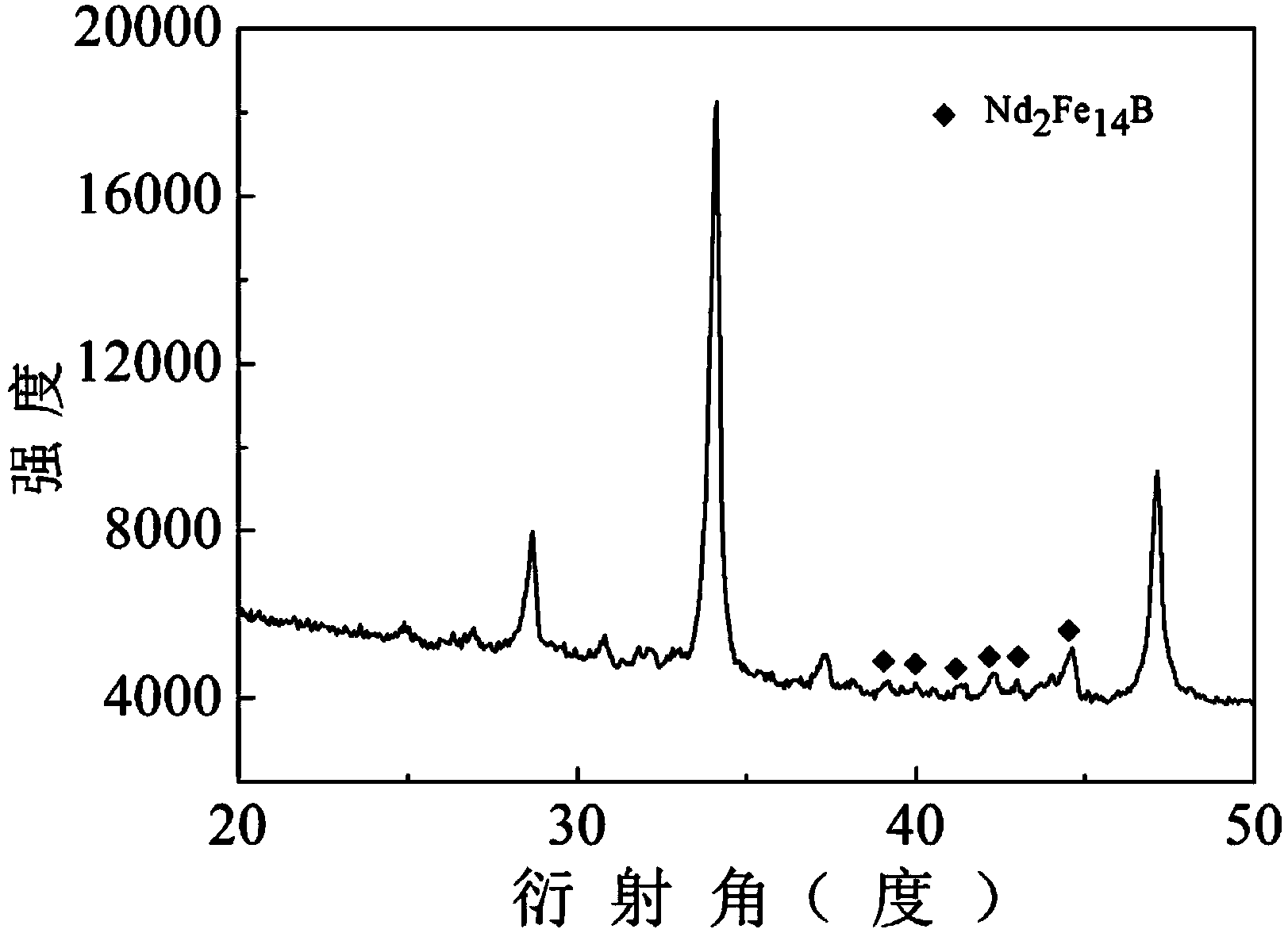

Embodiment 3

[0080] (1) Weigh 20g of NdFeB sludge and add 50ml of water to dissolve it in a beaker;

[0081] (2) Add the mixed liquid to the rotating bottle and fix it on the right end of the rotating shaft;

[0082] (3) Close the vacuum valve, vacuum, and maintain the pressure inside the tube at 0.1MPa;

[0083] (4) Set the temperature to 100°C, the rotation speed to 300rpm, adjust the height of the rotating bottle, turn on the heating button and the rotating button of the rotary evaporator, and start the water bath heating;

[0084] (5) Take out the remainder after the water has evaporated.

[0085] (6) Put the remainder in a beaker, add an appropriate amount of 4mol / L hydrochloric acid, add excess hydrogen peroxide to stir after dissolution, and remove non-metal elements such as B after filtration;

[0086] (7) Adjust the pH of the solution to 9 by adding ammonia with a volume ratio of 1:1, and let it stand for 2 hours;

[0087] (8) After centrifugation, dry the precipitate and place it in a box fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com