Low smoke halogen-free flame retardant material applicable to photovoltaic cable and manufacturing method thereof

A technology for photovoltaic cables and flame-retardant materials, which is applied in the field of low-smoke, halogen-free flame-retardant materials and their manufacturing, which can solve the problems of increasing cable manufacturing costs and usage costs, penetration of the outer sheath and insulation layer of cables, and inability to meet the use in humid environments and other problems, to achieve the effect of easy industrial promotion and production, good insulation and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

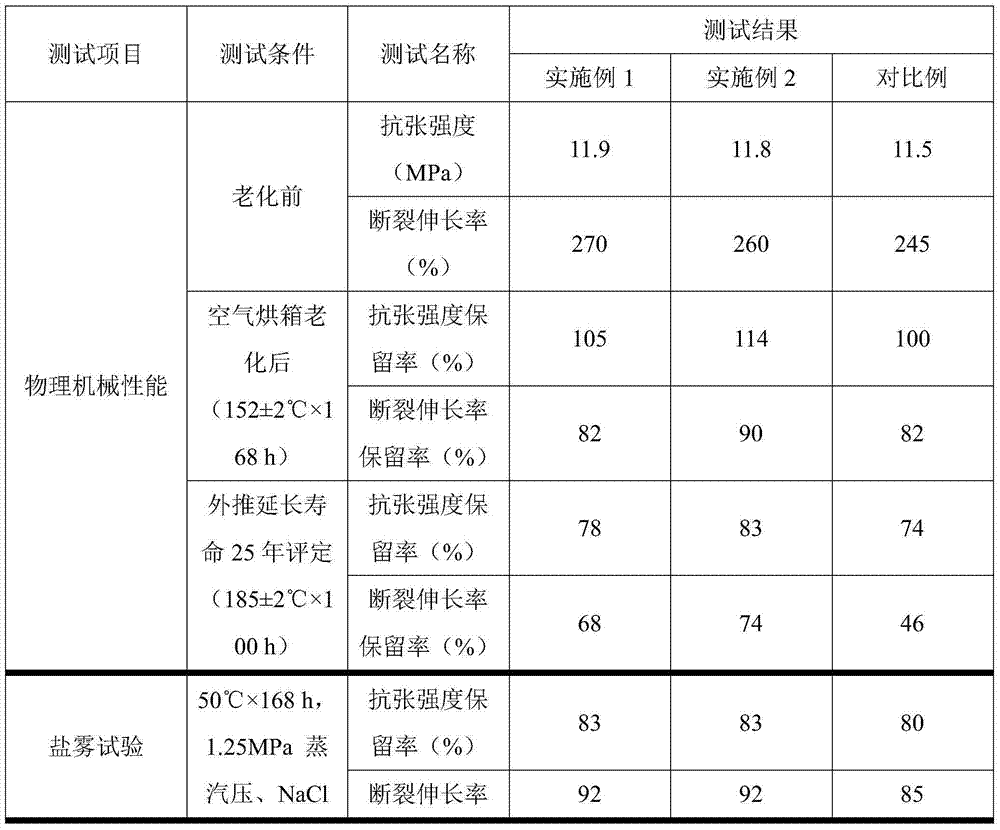

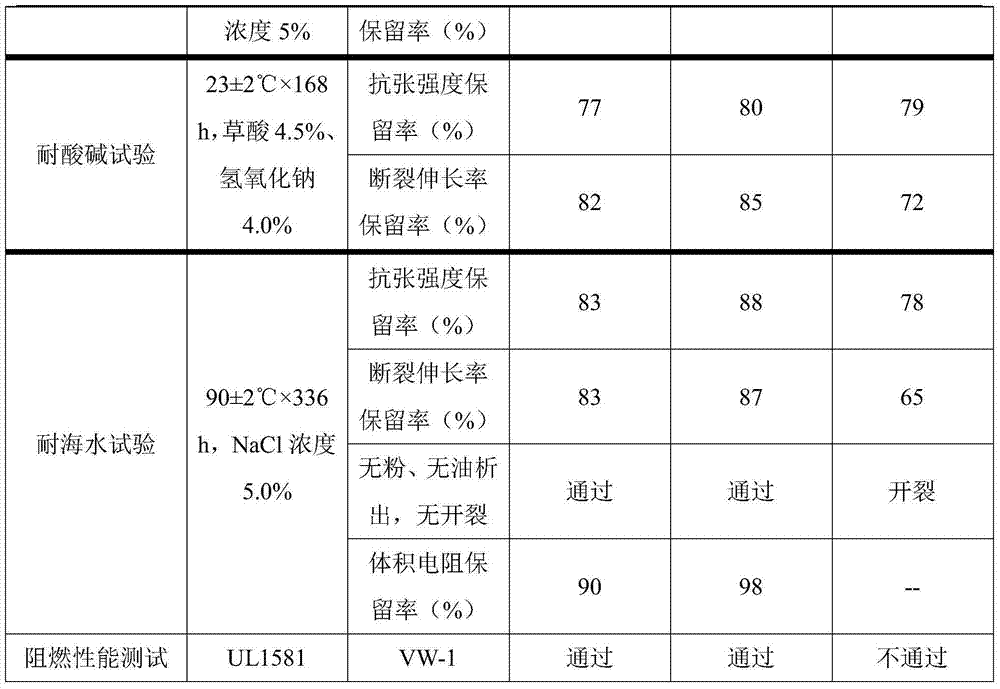

Examples

Embodiment 1

[0026] 32% (mass fraction) of EPDM rubber, 7% LLDPE, 8% silicone oil, 0.5% hydrophobic modifier, and 0.2% initiator (DCP) were sequentially added to the internal mixer for aerobic oil-filled chain-breaking dynamic vulcanization. Double-feeding, through twin-screw extrusion and granulation to obtain hydrophobically modified pellets A. Put 40% of aluminum hydroxide (ATH), 8% of melamine cyanurate (MCA), and 0.7% of hydrophobic silane coupling agent into a high-speed mixer in sequence, and perform physical blending for 10 minutes to obtain a uniformly dispersed hydrophobic flame retardant Agent B. Add hydrophobically modified material A, 0.8% antioxidant (AO), 1.5% carbon black (Cabot N220), 1% zinc stearate, and 0.3% EBS to the high mixer in order to neutralize the hydrophobic resistance. Fuel B is physically blended together. Put the uniformly mixed material into the internal mixer for high-temperature shear blending to make the material plasticized. The material is extruded ...

Embodiment 2

[0028] 30% (mass fraction) of polybutadiene rubber, 9% of MLLDPE, 6% of naphthenic oil, 0.5% of hydrophobic modifier, and 0.2% of initiator (DCP) were added to the internal mixer in sequence to carry out aerobic oil-filled chain breaking dynamic vulcanization, Hydrophobic modified pellets A are obtained through twin-screw extrusion and granulation through cone double feeding. Put 13% of aluminum hydroxide (ATH), 27% of magnesium hydroxide (MH), 10% of melamine cyanurate (MCA), and 0.5% of hydrophobic silane coupling agent into the high-speed mixer in sequence, and perform physical blending for 15 minutes , to obtain the hydrophobic flame retardant B evenly mixed and dispersed. Add hydrophobically modified particle A, 0.8% antioxidant (AO), 1.5% carbon black (Cabot N550), 0.5% zinc stearate, and 1% EBS to the high mixer in order to neutralize the hydrophobic flame retardant B are physically blended together. Put the uniformly mixed material into the internal mixer for high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com