A method for cleaning gallium lanthanum silicate wafer

A technology of lanthanum gallium silicate and wafers, which is applied in the directions of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., to achieve the effects of prolonging time, improving cleanliness, and improving cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

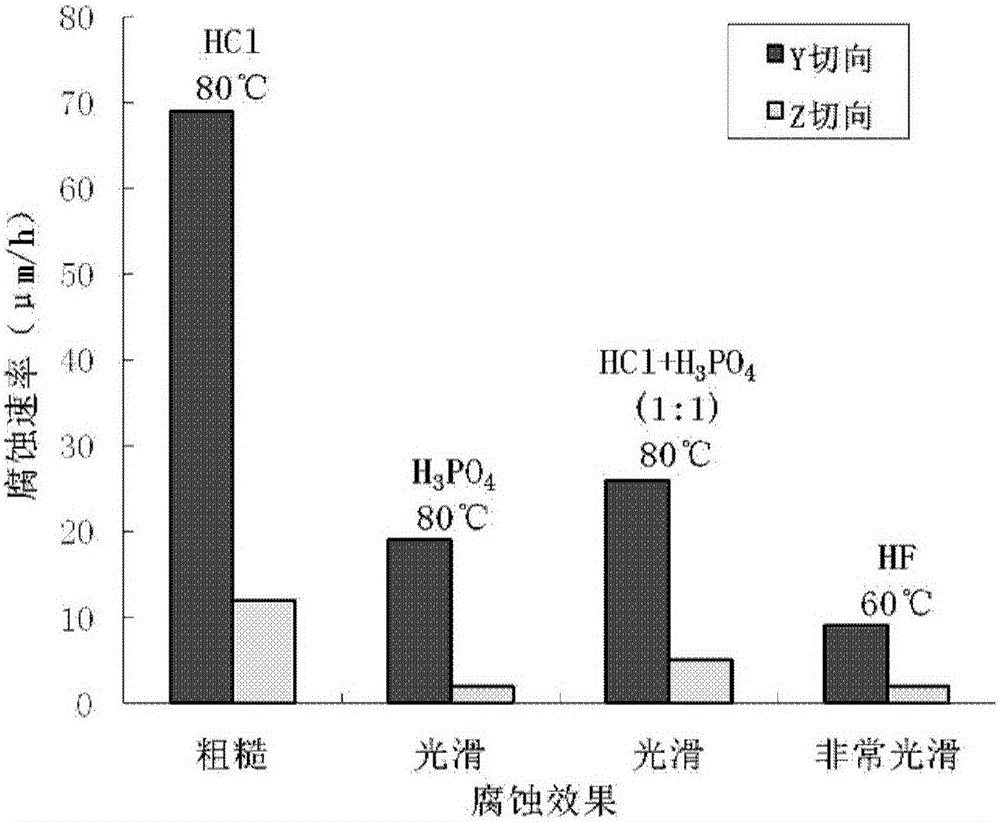

[0030] figure 1 It is a schematic diagram of the corrosion of gallium lanthanum silicate wafers by different acid solutions, showing that various acid solutions have certain corrosion effects on gallium lanthanum silicate wafers, but phosphoric acid is much less corrosive to gallium lanthanum silicate crystals than Hydrochloric acid is commonly used in traditional cleaning solutions.

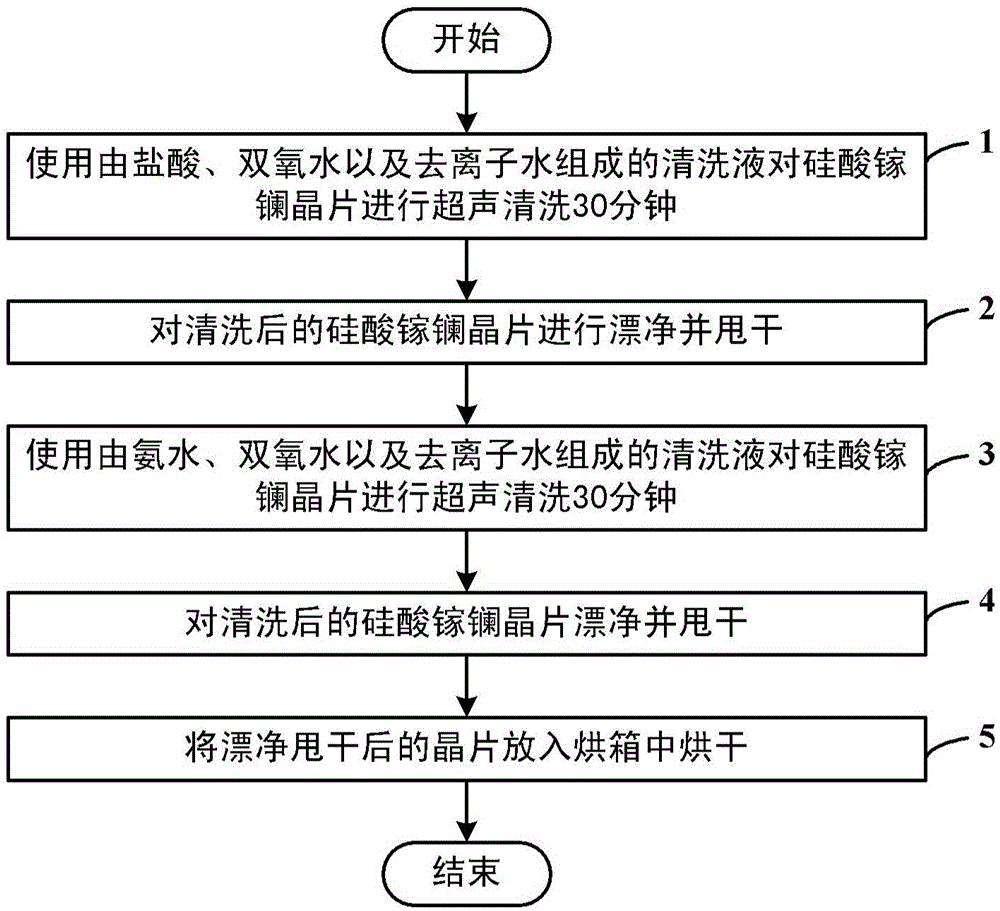

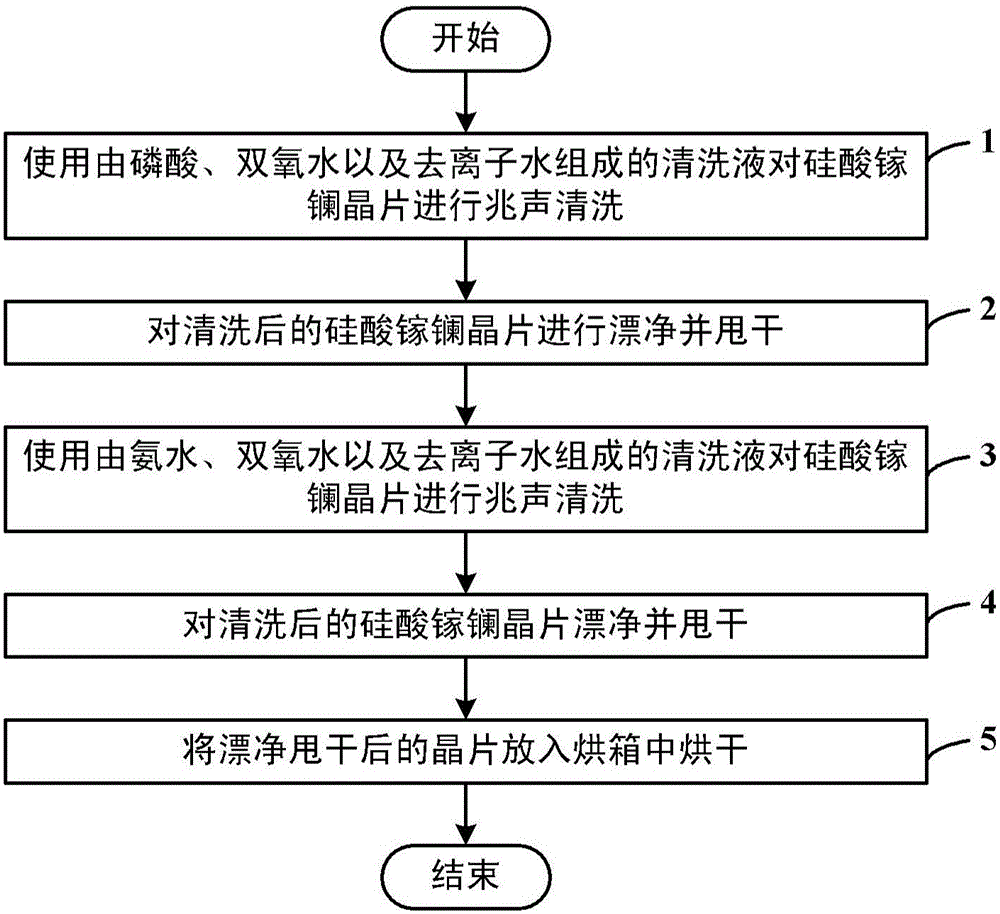

[0031] figure 2 It is a typical cleaning process flow chart commonly used in the traditional silicon integrated circuit industry. figure 2 It can be seen that in the traditional cleaning process, hydrochloric acid is often used as the main component of the acid cleaning solution, and the cleaning time of the acid cleaning solution is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com