Method for manufacturing double-layer graphene electrooptical modulator on basis of silicon substrate optical waveguide micro-ring resonant cavity

A micro-ring resonator, double-layer graphene technology, applied in the field of integrated optics, can solve the problems of increasing insertion loss, increasing process difficulty, etc., and achieve the effects of enhancing modulation strength, avoiding insertion loss, and small structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

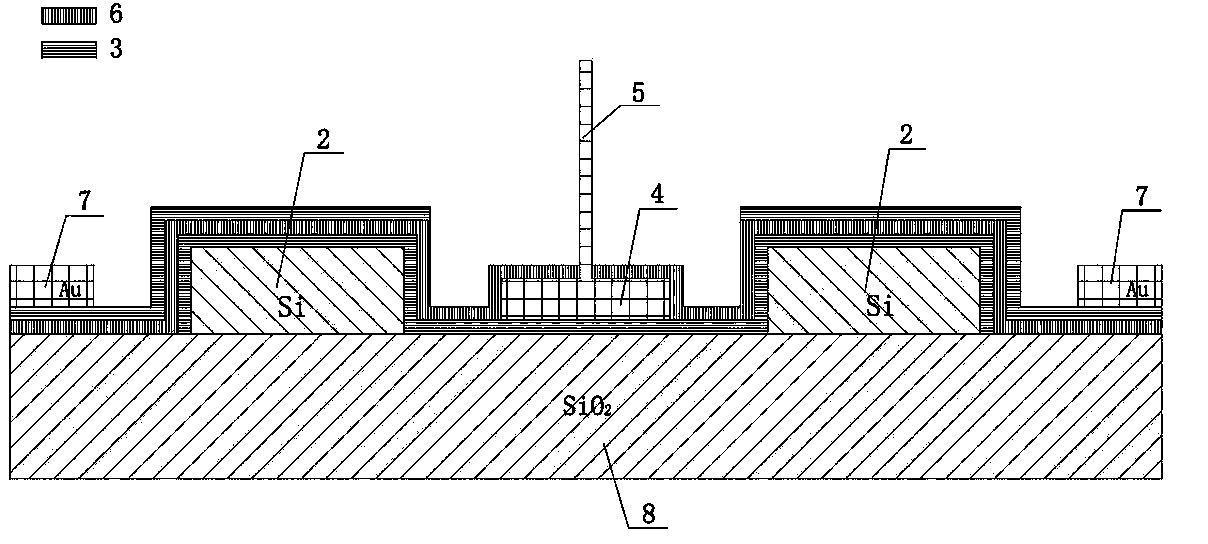

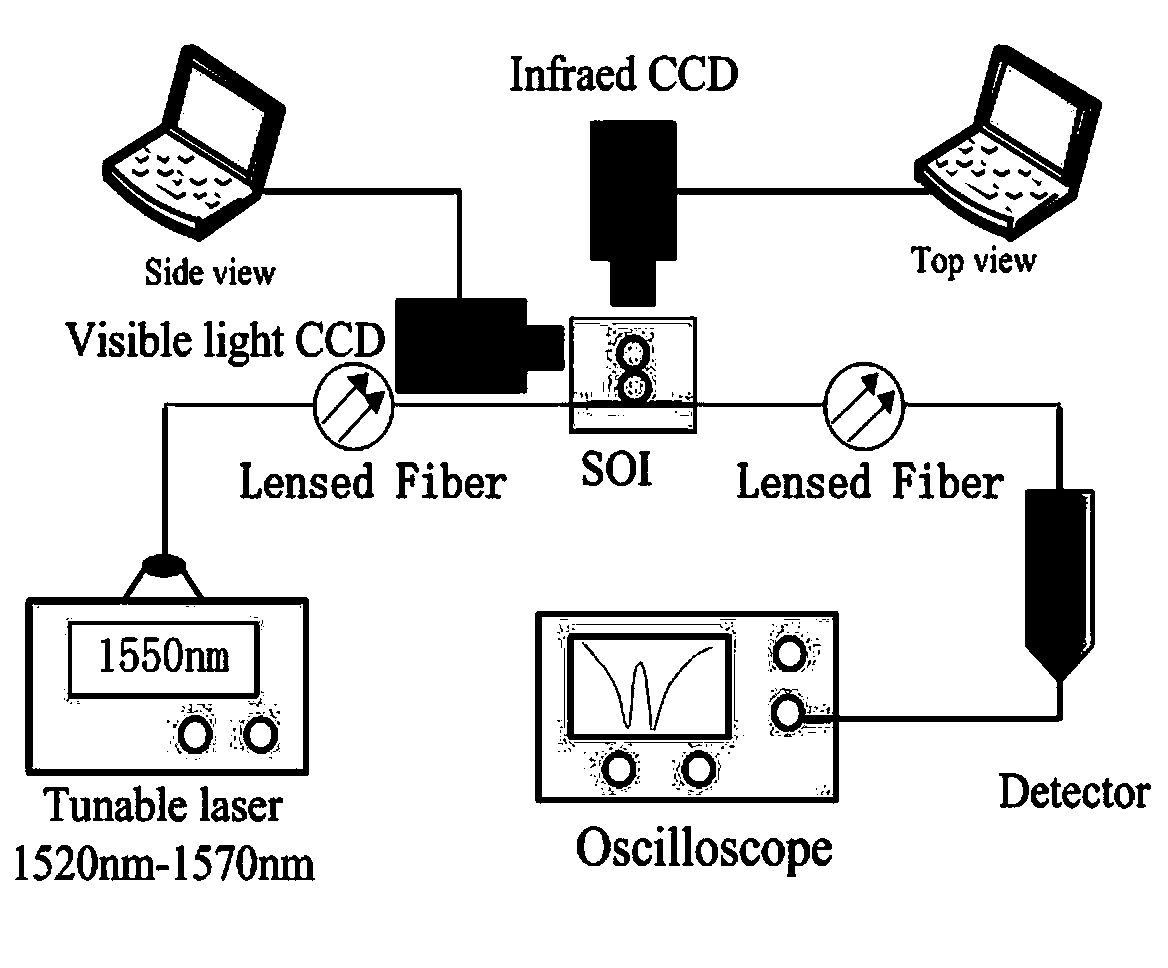

[0022] Such as figure 1 , 2 As shown, a method for preparing a double-layer graphene electro-optic modulator based on a silicon-based optical waveguide microring resonator comprises the following steps:

[0023] 1) Simulation and design of optical waveguide microring resonator

[0024] Use Optiwave-FDTD and Rsoft to simulate and analyze SOI-based micro-ring cavities with different parameters, screen out designs with higher Q values, and then prepare L-edit layouts for process tape-out;

[0025] 2) Process preparation of optical waveguide microring resonator

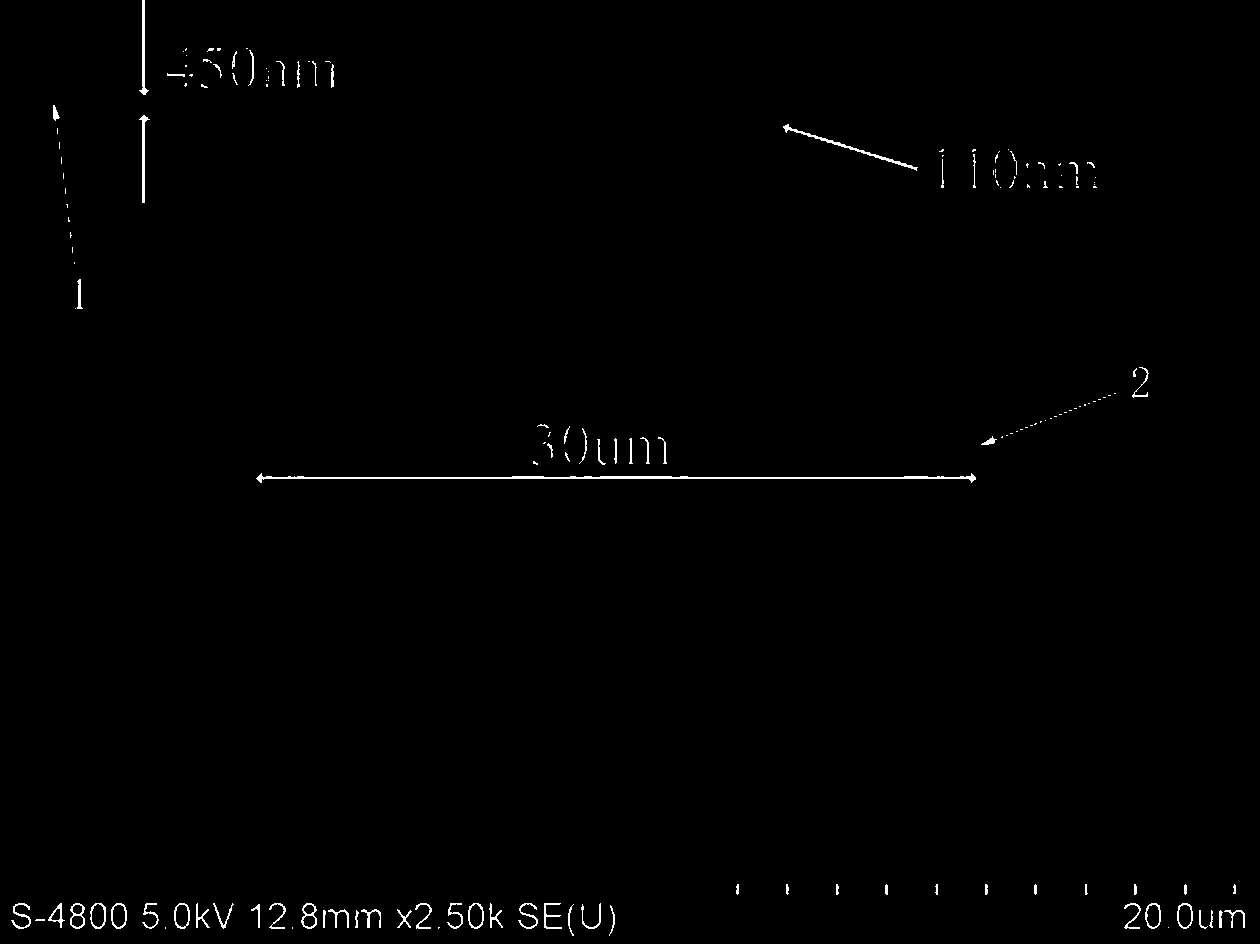

[0026] Take the existing SOI sheet, the silicon on the top layer of the existing SOI sheet is 220nm, and the thickness of the oxide layer is 3um. The SOI sheet is processed by electron beam lithography, ICP etching, and high temperature annealing process and the surface is smooth. Chemical treatment, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com