Bogie hearth for bogie hearth type resistance furnace

A trolley-type resistance furnace, trolley technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve problems such as short circuit, furnace bottom temperature cannot be guaranteed, affecting production safety, etc., to improve surface area, good resistance Oxidation performance, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

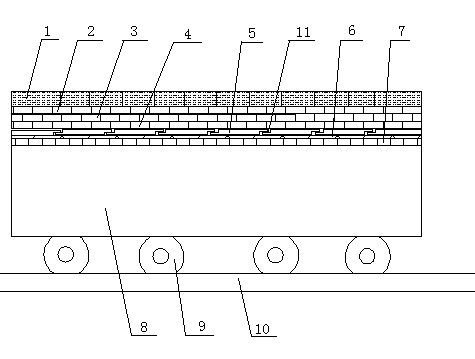

[0014] Such as figure 1 As shown, this embodiment provides a trolley for a trolley-type resistance furnace, and the cast iron 1 for the load-bearing workpiece, the refractory layer 2, the heat insulation layer 3, and the heat insulation layer 4 are sequentially arranged from top to bottom , floor layer 5, heating element 6, heat insulating brick 7 and car body 8, the refractory layer 2 adopts high alumina brick, the heat insulating layer 3 adopts diatomite brick, and the heat insulating second layer 4 adopts lightweight Clay bricks, the furnace bottom plate is made of heat-resistant steel, the bottom plate layer 5 is spliced by several strip-shaped furnace bottom plates, and the joints between adjacent furnace bottom plates are buckle-type, and the furnace bottom plate A gap 11 for thermal expansion and contraction is provided at the joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com