Fire preventing and extinguishing system for coal mine fully mechanized caving face in mining stopping period in flood season

A technology for fully mechanized caving surface and fire prevention, which is applied in the field of fire prevention systems and can solve the problems of poor heat dissipation conditions, difficulty in extinguishing fire, and large space for heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a fire prevention and extinguishing system for coal mine fully mechanized caving faces during the flood season. In order to make the purpose, technical scheme and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

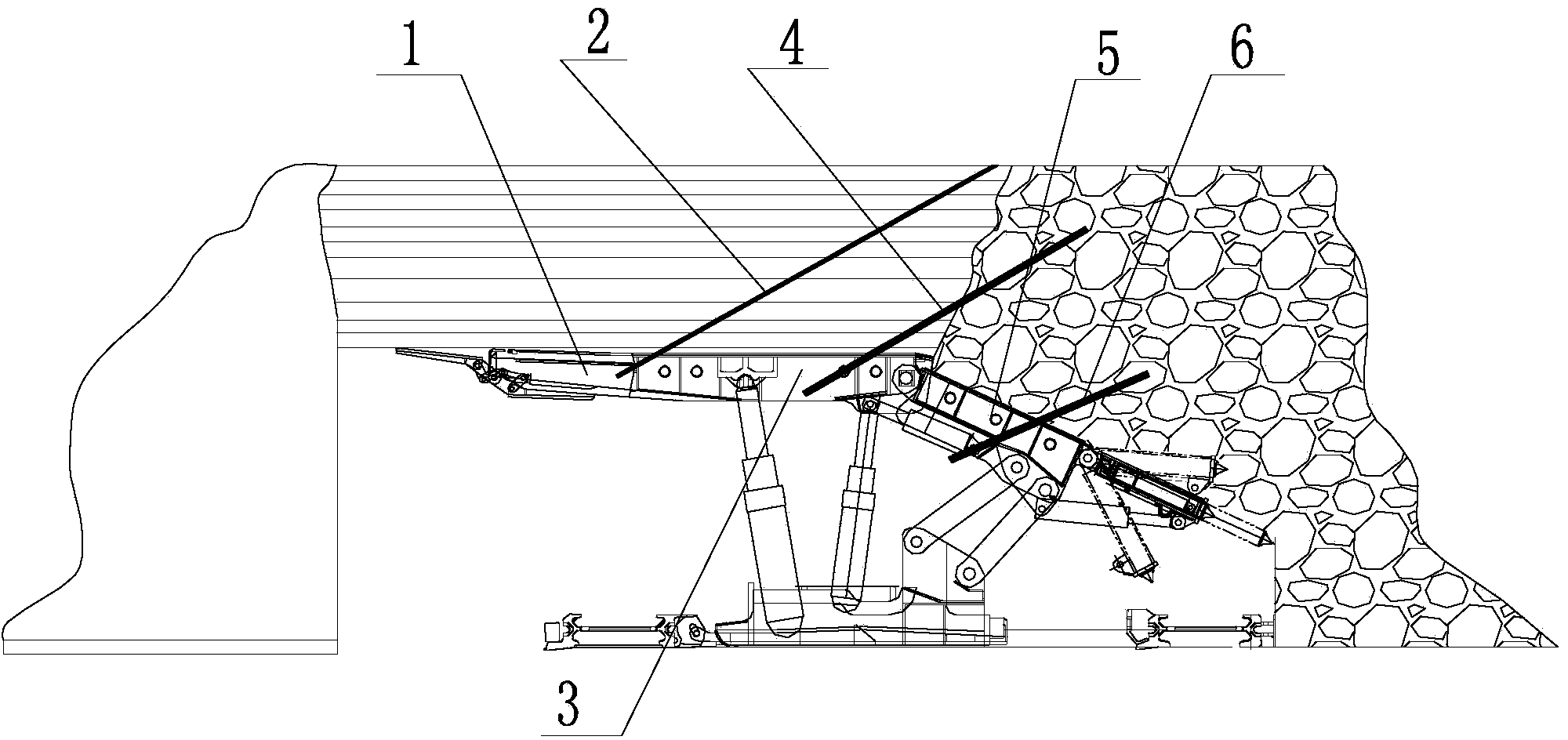

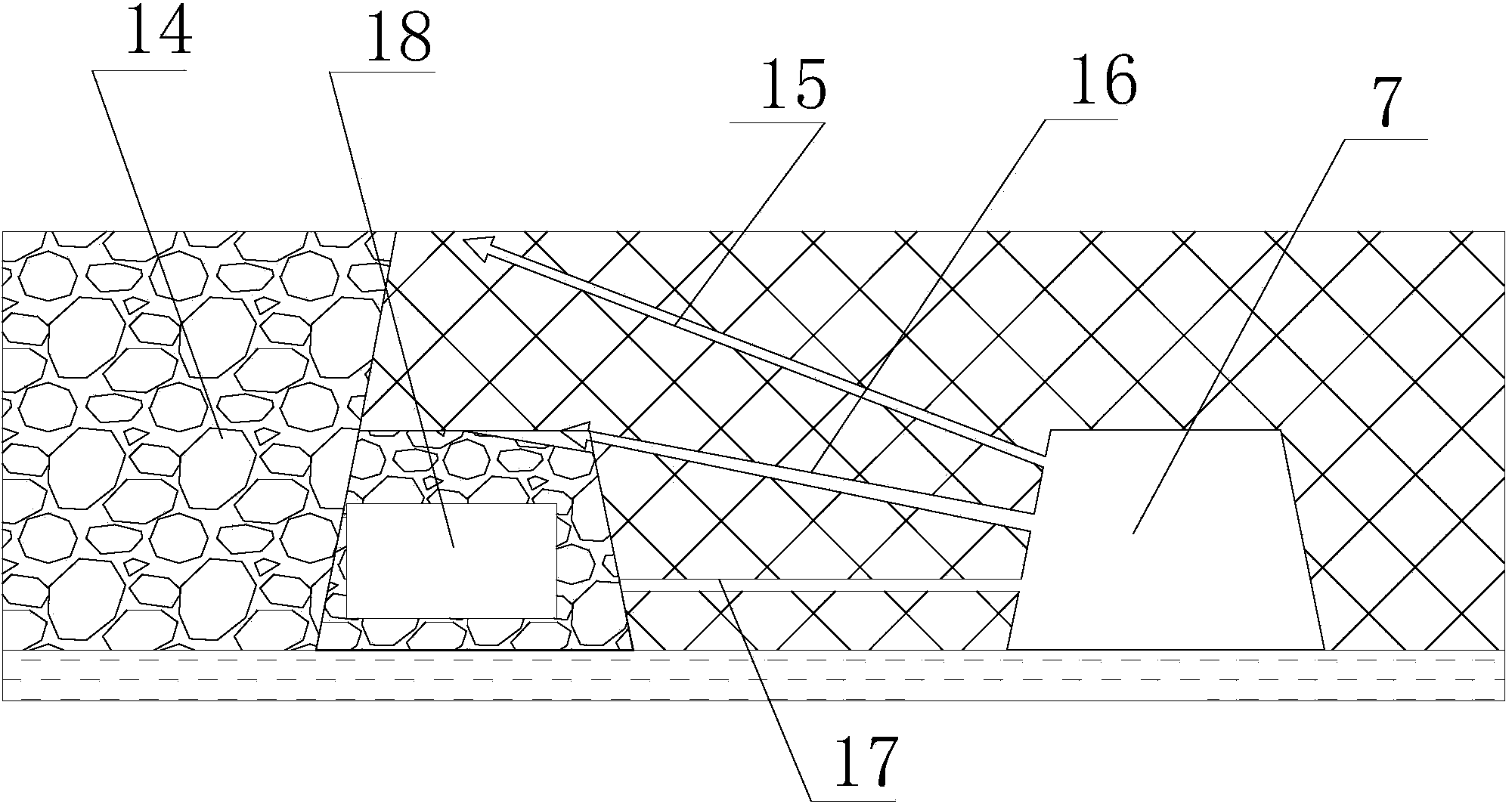

[0028] The invention provides a fire prevention and extinguishing system for fully mechanized caving faces during the flood season stoppage period, such as figure 1 and figure 2 shown, which includes:

[0029] Set the front drill hole 2 in the broken area of the top plate of the front beam frame 1 of each support in the fully mechanized caving face of the coal mine. The inclination angle is 30°~45°, and the depth is about 8m~10m;

[0030] Each support top beam 3 of the coal mine fully mechanized caving fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com