A method for preparing aliphatic polyester composites from surface-modified ctmp fibers

A technology of aliphatic polyester and composite materials, which is applied in fiber processing, plant fiber, textiles and papermaking, etc., can solve problems such as scarcity, achieve low cost, reduce agglomeration, and improve comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

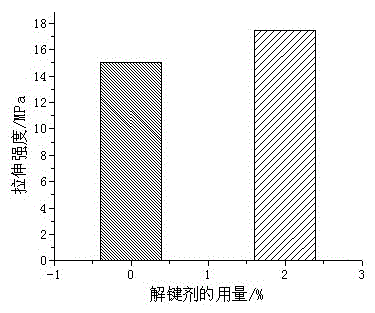

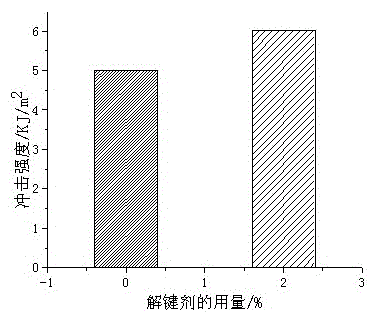

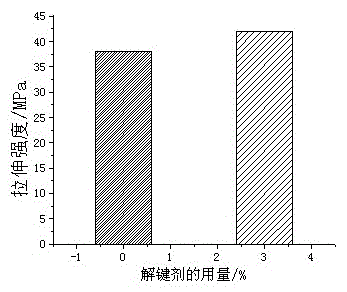

[0054] (1) Hydrophobic pretreatment of the surface of CTMP fibers by debonding agent:

[0055] First, dilute the debonding agent produced by Finland Kemira Company with deionized water into a 2% debonding agent solution by mass fraction;

[0056] Secondly, after dissolving the CTMP fiber for 3 minutes, configure it into a CTMP fiber solution with a mass fraction of 1%;

[0057] Finally, add the above-mentioned debonding agent solution into the above-mentioned CTMP fiber solution, and soak for 15 minutes to form a soaked CTMP fiber solution, wherein the mass ratio of the debonding agent to the dry CTMP fiber is 0.5:100;

[0058] (2) Preparation of CTMP fiber pulp sheet and dry dissociation of CTMP fiber after hydrophobic treatment:

[0059] Prepare the pretreated CTMP fiber into a CTMP fiber pulp sheet with a quantitative weight of 400g / ㎡ on the laboratory sheet machine, and dry it by blasting at 80°C;

[0060] Dry and dissociate the dried paddles in a high-speed mixer at a s...

Embodiment 2

[0066] (1) Hydrophobic pretreatment of the surface of CTMP fibers by debonding agent:

[0067] First, the deionized water produced by a certain company in Shandong Province is diluted into a bond-breaking agent solution with a mass fraction of 3%;

[0068] Secondly, after dissolving the CTMP fiber for 3 minutes, configure it into a CTMP fiber solution with a mass fraction of 1%;

[0069] Finally, add the above-mentioned debonding agent solution into the above-mentioned CTMP fiber solution, and soak for 15 minutes to form a soaked CTMP fiber solution, wherein the mass ratio of the debonding agent to the dry CTMP fiber is 4:100;

[0070] (2) Preparation of CTMP fiber pulp sheet and dry dissociation of CTMP fiber after hydrophobic treatment:

[0071] Prepare the pretreated CTMP fiber into a CTMP fiber pulp sheet with a quantitative weight of 400g / ㎡ on the laboratory sheet machine, and dry it by blasting at 80°C;

[0072] Dry and dissociate the dried paddles in a high-speed mixe...

Embodiment 3

[0077] (1) Hydrophobic pretreatment of the surface of CTMP fibers by debonding agent:

[0078] First, dilute the debonding agent produced by a company in Deyang, Sichuan, with deionized water into a debonding agent solution with a mass fraction of 5%;

[0079] Secondly, after dissolving the CTMP fiber for 3 minutes, configure it into a CTMP fiber solution with a mass fraction of 1%;

[0080] Finally, add the above-mentioned debonding agent solution into the above-mentioned CTMP fiber solution, and soak for 15 minutes to form a soaked CTMP fiber solution, wherein the mass ratio of debonding agent to dry CTMP fiber is 5:100;

[0081] (2) Preparation of CTMP fiber pulp sheet and dry dissociation of CTMP fiber after hydrophobic treatment:

[0082] The pretreated masson pine CTMP fiber was prepared into a CTMP fiber pulp sheet with a quantitative weight of 400g / ㎡ on the laboratory sheet machine, and was blown and dried at 80°C;

[0083] Dry and dissociate the dried paddles in a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com