Nitrile rubber material for high-performance engine

A technology of nitrile rubber and engine, applied in the field of nitrile rubber, can solve the problem of not meeting the engine, etc., and achieve the effect of improving surface gloss, excellent flame retardant performance, excellent heat resistance and ozone resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

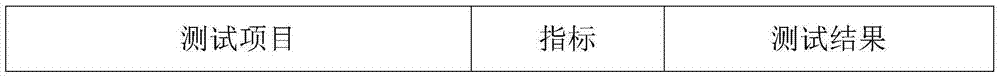

Embodiment 1

[0015] In the present embodiment, a kind of nitrile rubber material for high-performance engine, its raw material comprises by weight:

[0016] 360475 parts of nitrile rubber, 22 parts of EPDM rubber, 8 parts of silicone modified acrylate, 4.5 parts of polyvinyl chloride resin, 1.25 parts of stearic acid, 2.3 parts of paraffin, 55 parts of carbon black N5505, 28 parts of zinc oxide whiskers Parts, 9 parts of coupling agent KH-5509, 16 parts of high styrene, 0.95 parts of trimethylolmethylamine, 2 parts of dicumyl peroxide, 0.65 parts of N,N-diphenyl-p-phenylenediamine, anti-aging 0.45 parts of agent MB, 0.9 parts of trimethylolpropane trimethacrylate, 1.2 parts of triallyl isocyanurate, 5 parts of magnesium hydroxide, 2.5 parts of antimony trioxide, diethylene glycol 12 parts of benzoate, 0.9 parts of accelerator TMTD;

[0017] Among them, the content of acrylonitrile in nitrile rubber 3604 is 38%, the volatile matter is 0.92%, the tensile strength is 34MPa; the content of bo...

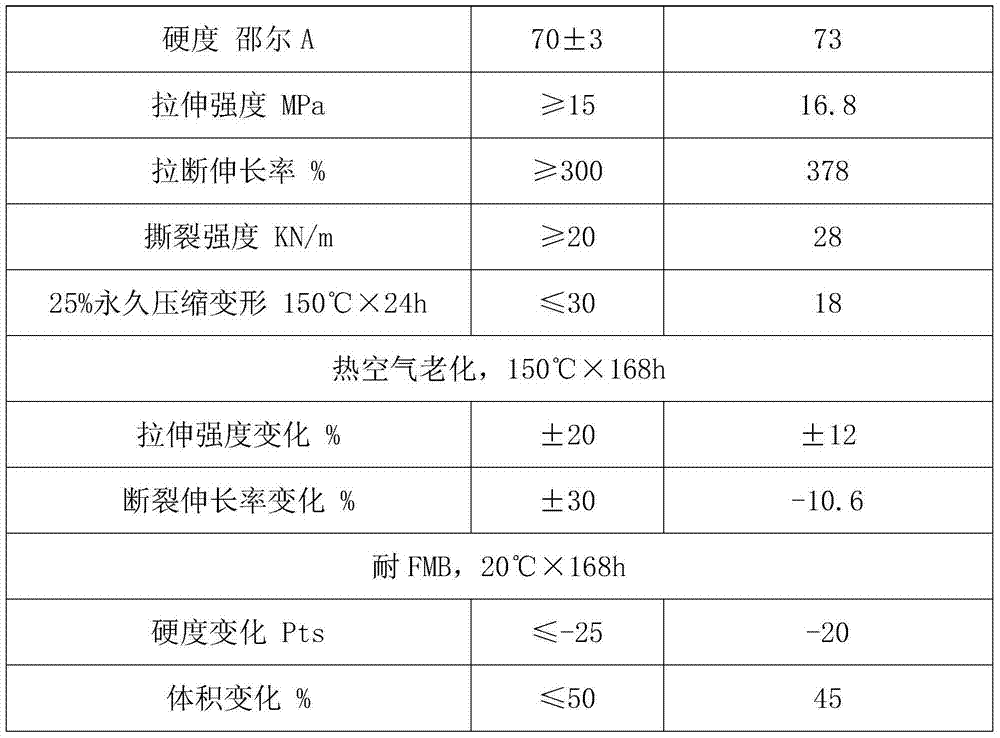

Embodiment 2

[0022] In the present embodiment, a kind of nitrile rubber material for high-performance engine, its raw material comprises by weight:

[0023] 360485 parts of nitrile rubber, 23 parts of EPDM rubber, 9 parts of silicone modified acrylate, 5 parts of polyvinyl chloride resin, 1.2 parts of stearic acid, 2.3 parts of paraffin wax, 8 parts of carbon black N55058, 26 parts of zinc oxide whiskers Parts, coupling agent KH-55011 parts, high styrene 14 parts, trimethylolmethylamine 1.25 parts, dicumyl peroxide 2.05 parts, N,N-diphenyl-p-phenylenediamine 0.7 parts, anti-aging 0.45 parts of agent MB, 0.8 parts of trimethylolpropane trimethacrylate, 1.15 parts of triallyl isocyanurate, 7 parts of magnesium hydroxide, 1.25 parts of antimony trioxide, diethylene glycol 12 parts of benzoate, 0.7 part of accelerator TMTD;

[0024] Among them, the content of acrylonitrile in nitrile rubber 3604 is 38.4%, the volatile matter is 0.92%, the tensile strength is 33.5MPa; the content of bound benz...

Embodiment 3

[0028] In the present embodiment, a kind of nitrile rubber material for high-performance engine, its raw material comprises by weight:

[0029] 360495 parts of nitrile rubber, 24 parts of EPDM rubber, 9 parts of silicone modified acrylate, 4.5 parts of polyvinyl chloride resin, 0.95 parts of stearic acid, 2.03 parts of paraffin, 55 parts of carbon black N5505, 24 parts of zinc oxide whiskers 1.5 parts, coupling agent KH-55011.5 parts, high styrene 16 parts, trimethylolmethylamine 0.85 parts, dicumyl peroxide 2.1 parts, N,N-diphenyl-p-phenylenediamine 0.7 parts, anti-aging 0.45 parts of agent MB, 0.93 parts of trimethylolpropane trimethacrylate, 1.6 parts of triallyl isocyanurate, 7.3 parts of magnesium hydroxide, 2.6 parts of antimony trioxide, diethylene glycol 12.7 parts of benzoic acid esters, 0.9 parts of accelerator TMTD;

[0030] Among them, the content of acrylonitrile in nitrile rubber 3604 is 38.2%, the volatile matter is 1%, the tensile strength is 32MPa; the conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com