A kind of preparation method of radiation crosslinking modified gelatin film

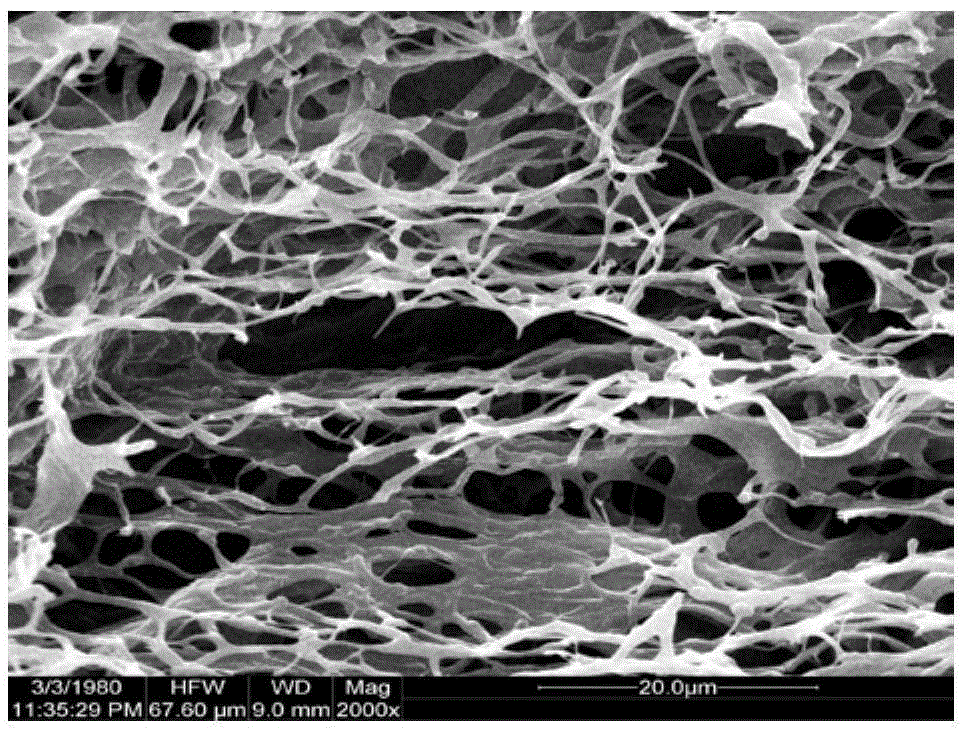

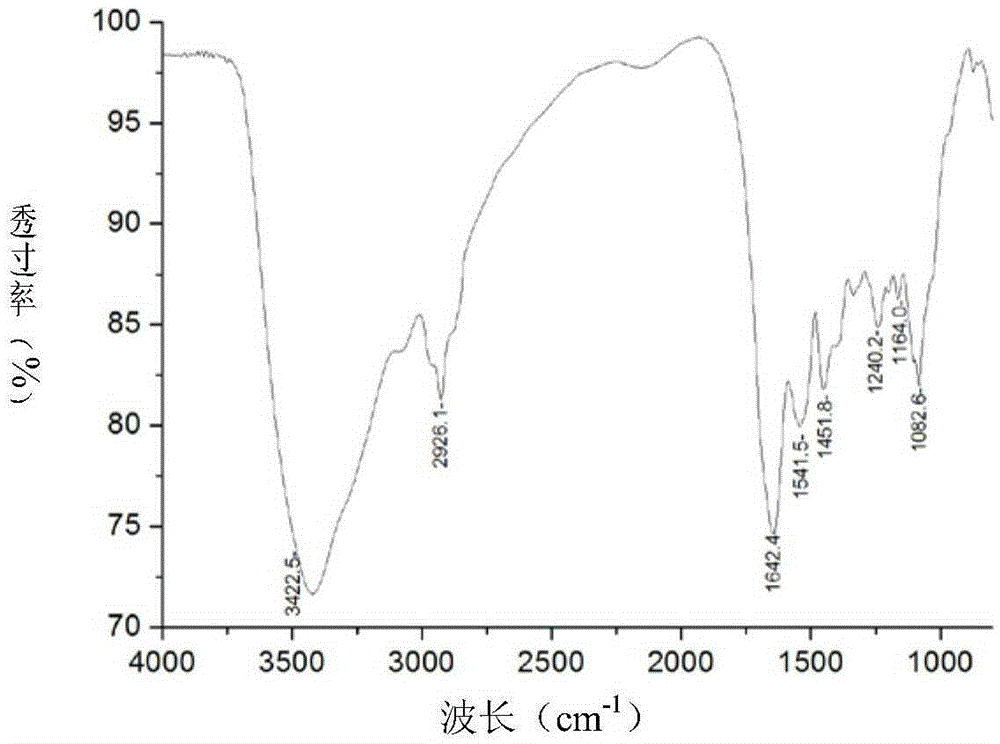

A technology of cross-linking modification and gelatin film, which is applied in the fields of medicine and food, which can solve the problems of chemical substance residue, gelatin biological activity and stability decline, etc., and achieve excellent performance, reduce the difficulty of gelatin film removal, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for radiation cross-linked modified gelatin film, comprising the steps of:

[0027] 1) Preparation of gelatin-glycerol aqueous solution: Weigh 5 grams of gelatin and 40 grams of water, mix and swell at room temperature for 1 hour, dissolve in a water bath at 50° C., add 1 gram of glycerin, and mix well to obtain a gelatin-glycerin aqueous solution for use;

[0028] 2) Preparation of the anti-sticking layer of the tray: Weigh 10 grams of sodium stearate and 90 grams of water, mix them, dissolve them in hot water at 90°C, and adjust the pH of the sodium stearate-water mixture to 8 with 30wt% NaOH aqueous solution to obtain a paste (at this time, the paste changes from white to transparent); spread the paste evenly on the bottom of the tray, let it dry to form an anti-adhesive layer, and wait for use (a tray coated with an anti-adhesive layer);

[0029] 3) Pour the gelatin-glycerin aqueous solution into a tray coated with an anti-stick layer, and cool ...

Embodiment 2

[0046] A preparation method for radiation cross-linked modified gelatin film, comprising the steps of:

[0047] 1) Preparation of gelatin-glycerol aqueous solution: Weigh 5 grams of gelatin, 40 grams of water, swell at room temperature for 1 hour after mixing, dissolve in a water bath at 50° C., add 2 grams of glycerin, mix to obtain a gelatin-glycerin aqueous solution, and set aside;

[0048] 2) Preparation of the anti-sticking layer of the tray: Weigh 10 grams of sodium stearate and 90 grams of water, mix them, dissolve them in hot water at 90°C, and adjust the pH of the sodium stearate-water mixture to 8 with 30wt% NaOH aqueous solution to obtain a paste (at this time, the paste changes from white to transparent); spread the paste evenly on the bottom of the tray, let it dry to form an anti-adhesive layer, and wait for use (a tray coated with an anti-adhesive layer);

[0049] 3) Pour the gelatin-glycerin aqueous solution into a tray coated with an anti-stick layer, and cool...

Embodiment 3

[0056] A preparation method for radiation cross-linked modified gelatin film, comprising the steps of:

[0057] 1) Preparation of gelatin-glycerol aqueous solution: Weigh 5 grams of gelatin, 40 grams of water, swell at room temperature for 40 minutes after mixing, dissolve in a water bath at 55° C., add 2.5 grams of glycerin, and mix well to obtain a gelatin-glycerin aqueous solution for use;

[0058] 2) Preparation of the anti-sticking layer of the tray: Weigh 10 grams of sodium stearate and 90 grams of water, mix them, dissolve them in hot water at 90°C, and adjust the pH of the sodium stearate-water mixture to 9 with 20wt% NaOH aqueous solution to obtain a paste (at this time, the paste changes from white to transparent); spread the paste evenly on the bottom of the tray, let it dry to form an anti-adhesive layer, and wait for use (a tray coated with an anti-adhesive layer);

[0059] 3) Pour the gelatin-glycerin aqueous solution into a tray coated with an anti-sticking laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com