3D printer

A 3D printer and printer technology, applied in the field of 3D printers, can solve problems affecting workpiece quality, workpiece deformation, invalid movement, etc., and achieve the effects of accurate and reliable transmission of movement, increasing friction coefficient, and ensuring a constant temperature state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

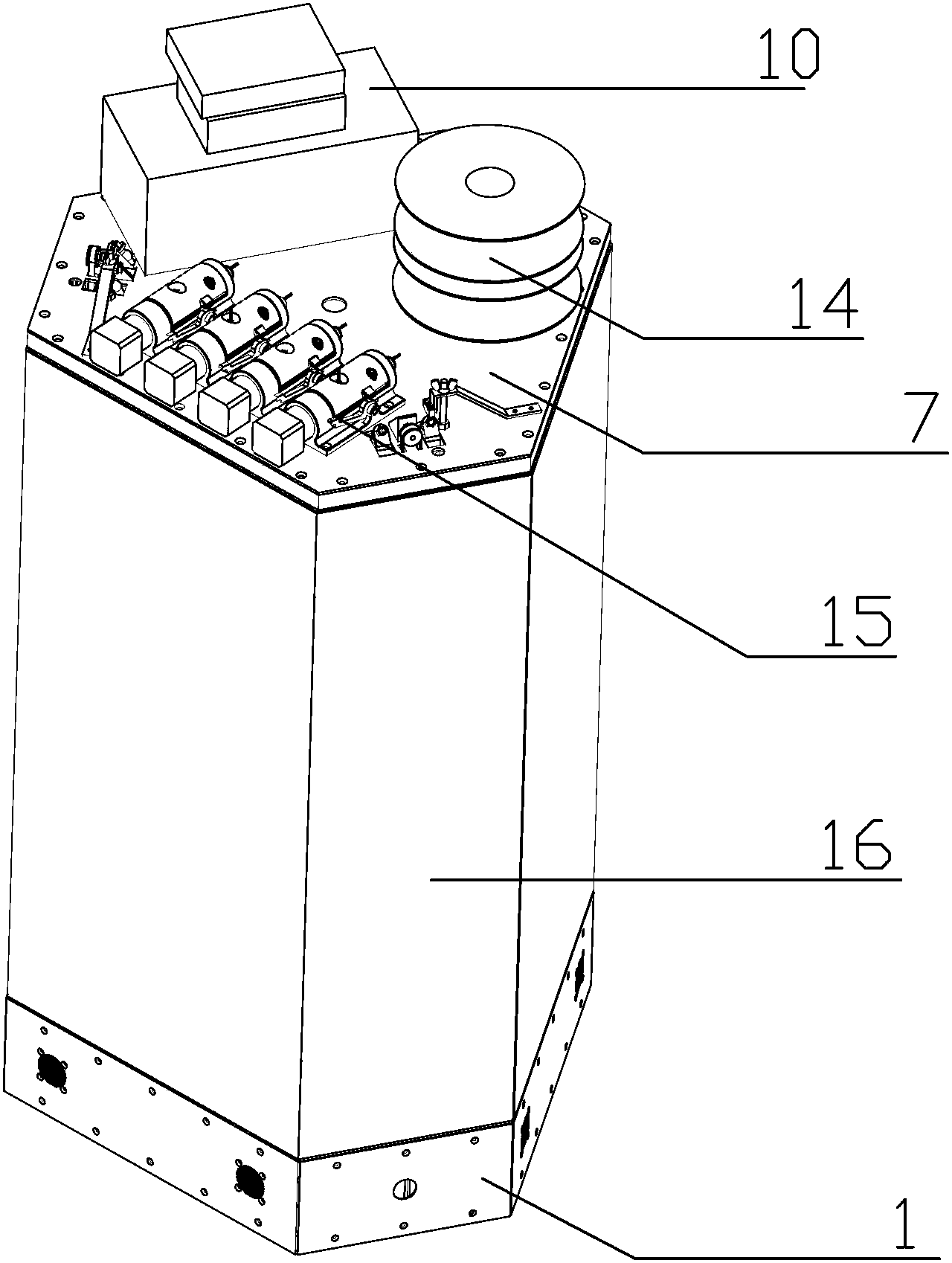

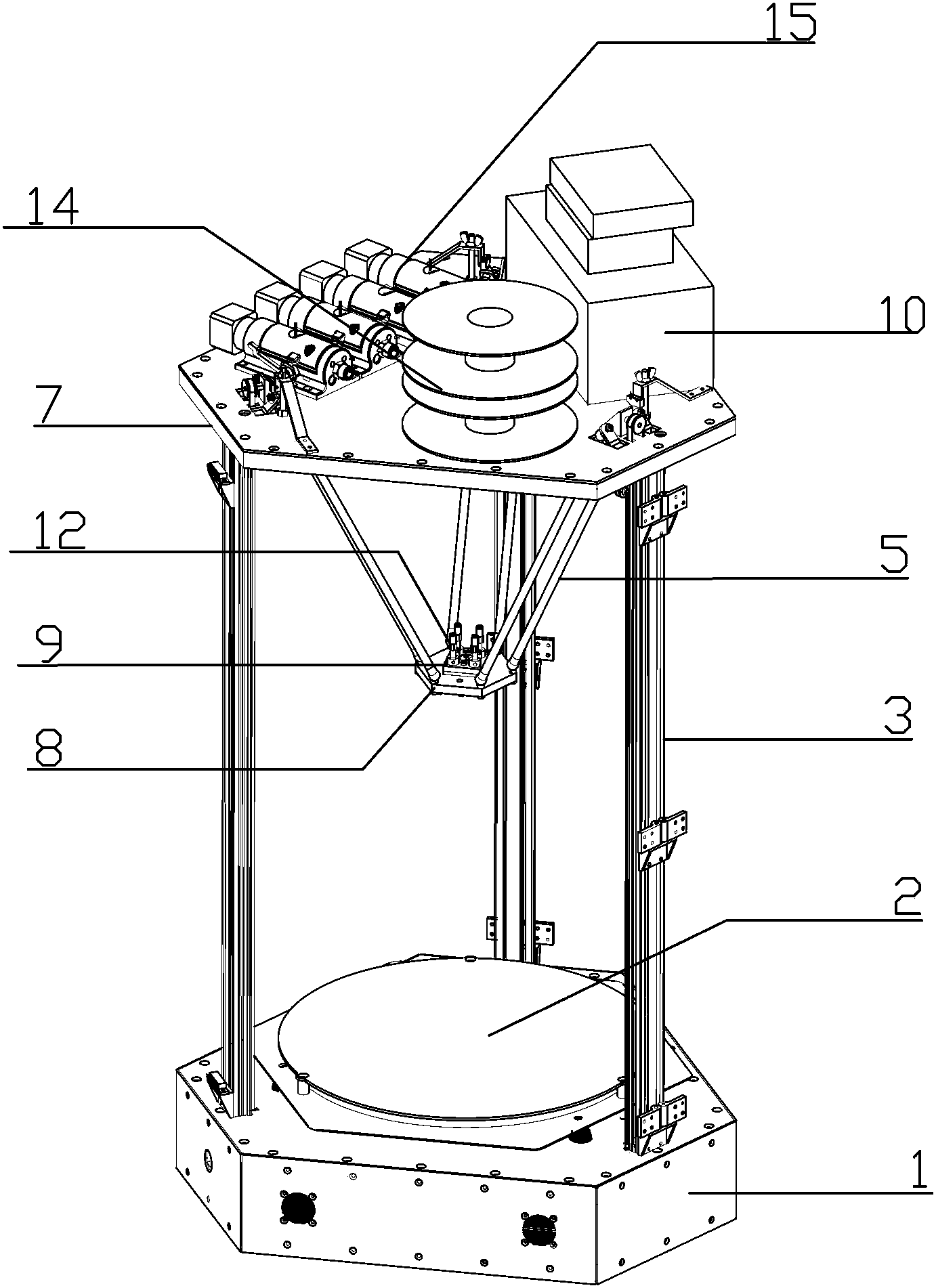

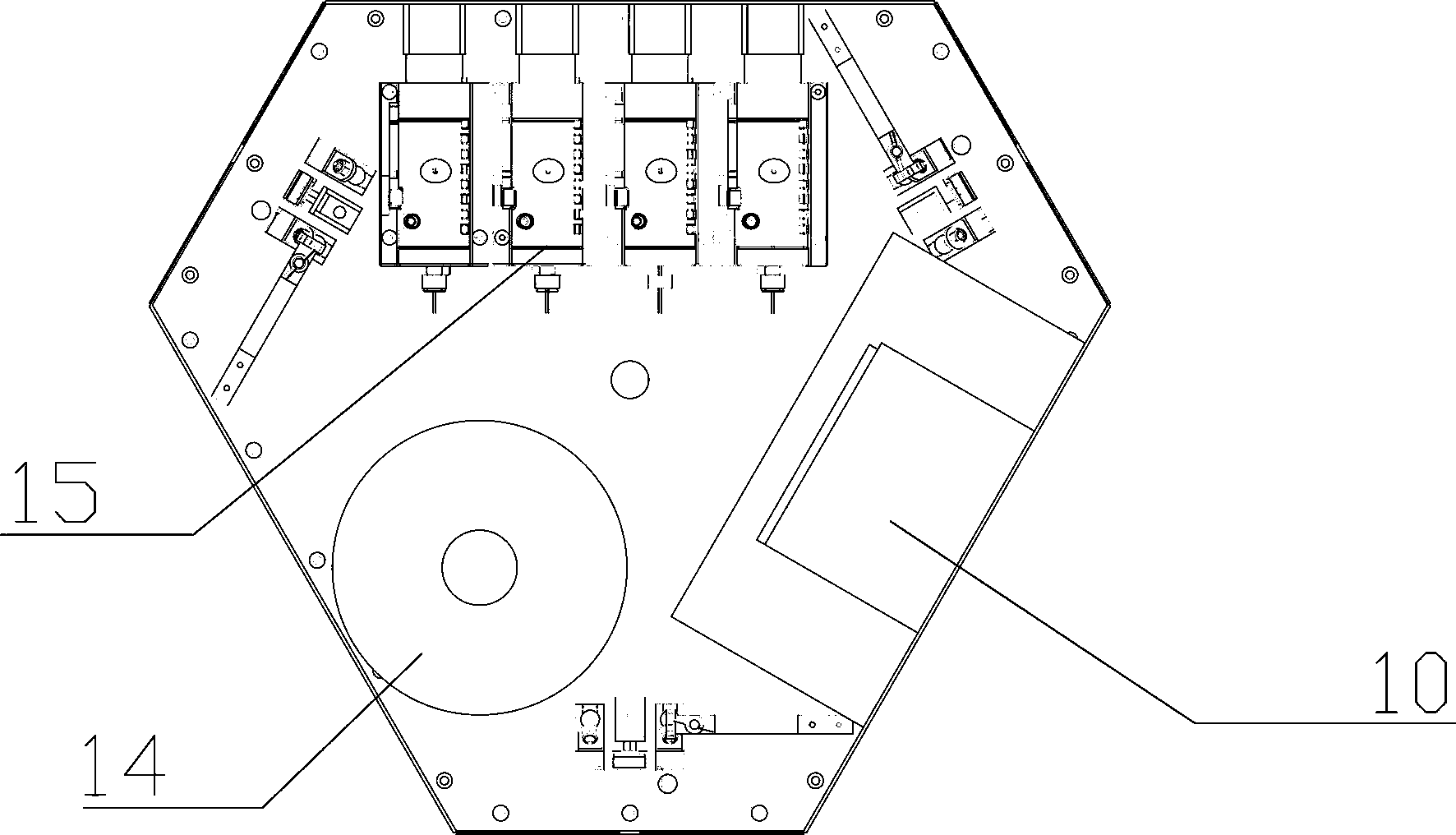

[0034] Embodiment 1: the 3D printer of the present invention is characterized in that it comprises a transmission mechanism, a workbench 8, a feeding mechanism 15, and an isolation device 16;

[0035] The transmission mechanism consists of the following devices:

[0036] The base 1 is a hollow platform, and the upper surface of the base 1 is provided with a heating assembly I2; the transmission assembly includes a linear slide rail 3, a slider 4, a connecting rod 5 and a drive motor 6, and at least three vertically distributed linear slide rails 3 are fixed on the edge of the base 1, A steel ball is provided at the contact between each linear slide rail 3 and the slider 4; the slider 4 is connected with the drive motor 6 in the base 1 in a wire transmission mode, and the slider 4 is fixed on the line; the drive motor 6 is fixed on the shaft There is a driving wheel, the top of the linear slide rail 3 is pivotally connected to the driven wheel, the driving wheel and the driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com