Coating dryer and air nozzle special for coating dryer

A drying and coating technology, which is applied to the device, coating, pretreatment surface, etc. for coating liquid on the surface. The layer thickness is inconsistent, ensuring stability and the effect of stable thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

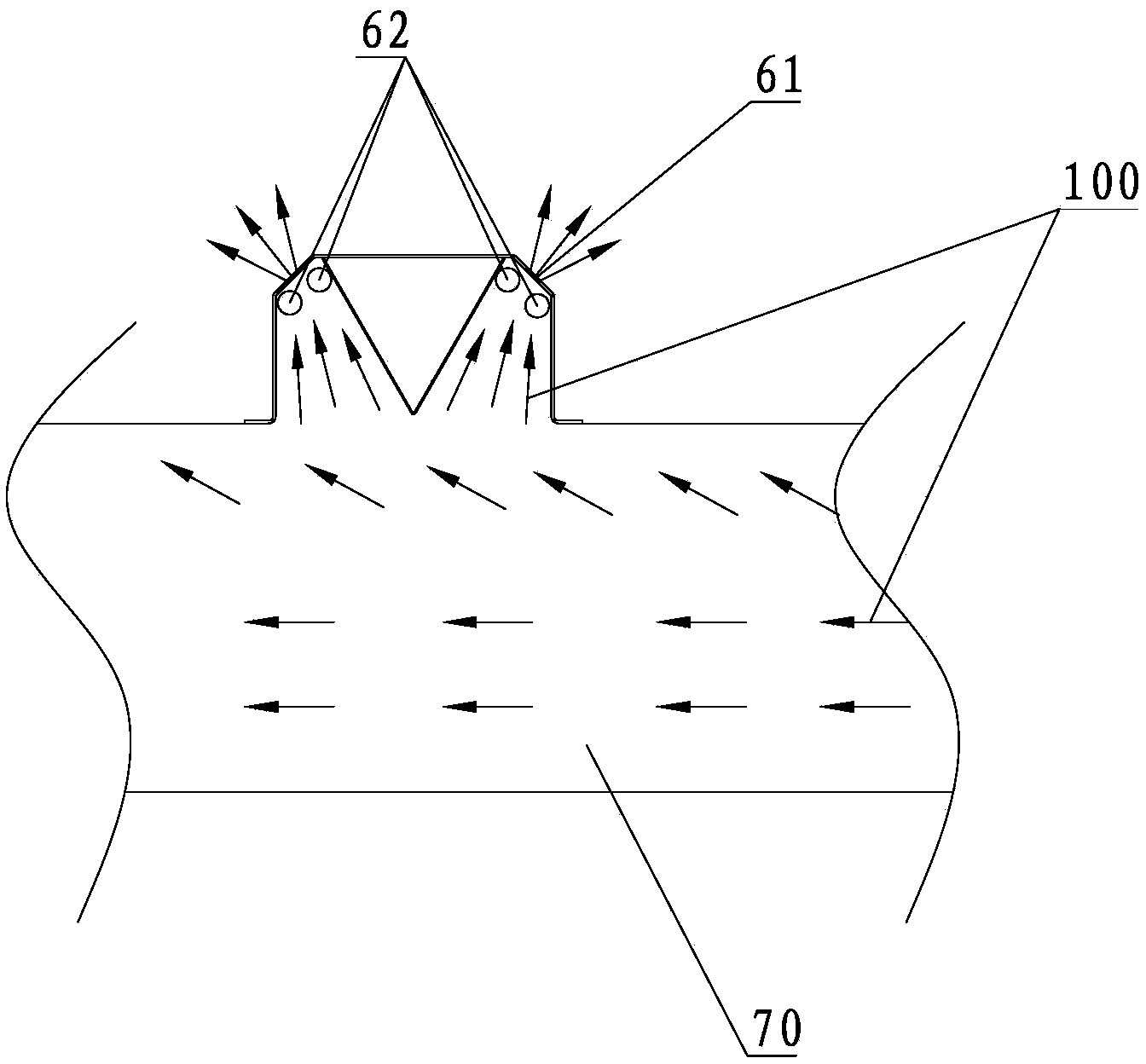

[0017] In the above structure, the section of the air chamber 40 of the air nozzle is an isosceles triangle, and the straight-through section is connected to the apex of the isosceles triangle. As a general choice, the shape of the air chamber 40 will not affect the wind speed of the wind blown out of the final air outlet. However, if the air chamber is designed as an isosceles triangle, not only can the fluid flow into the air chamber 40 of the air nozzle have better fluidity, but also the structure of the air chamber 40 can be easily produced.

Embodiment 2

[0019] In the above structure, the length of the straight section is not less than 20mm. It can be seen from the above that the straight-through section 41 plays a key role in the tuyere, and in order to ensure its pressure equalization effect, the length of the straight-through section should not be less than 20 mm. Theoretically, it is the same as the principle of increasing the barrel length and the stability of the outgoing shells, so the longer the straight-through section can have a better balance on the passing wind, but considering the actual product application environment, after repeated experiments , optimally, the length of the through section is 20-28mm is optimal.

Embodiment 3

[0021] In order to ensure a better wind speed, the inner diameter of the straight-through section should be designed at 3-5mm, which is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com