Motor control device and work machine using same

A technology for motor control and operating machinery, applied in the field of motor control devices and operating machinery, can solve problems such as the reduction of torque control accuracy, and achieve the effect of high-precision torque control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

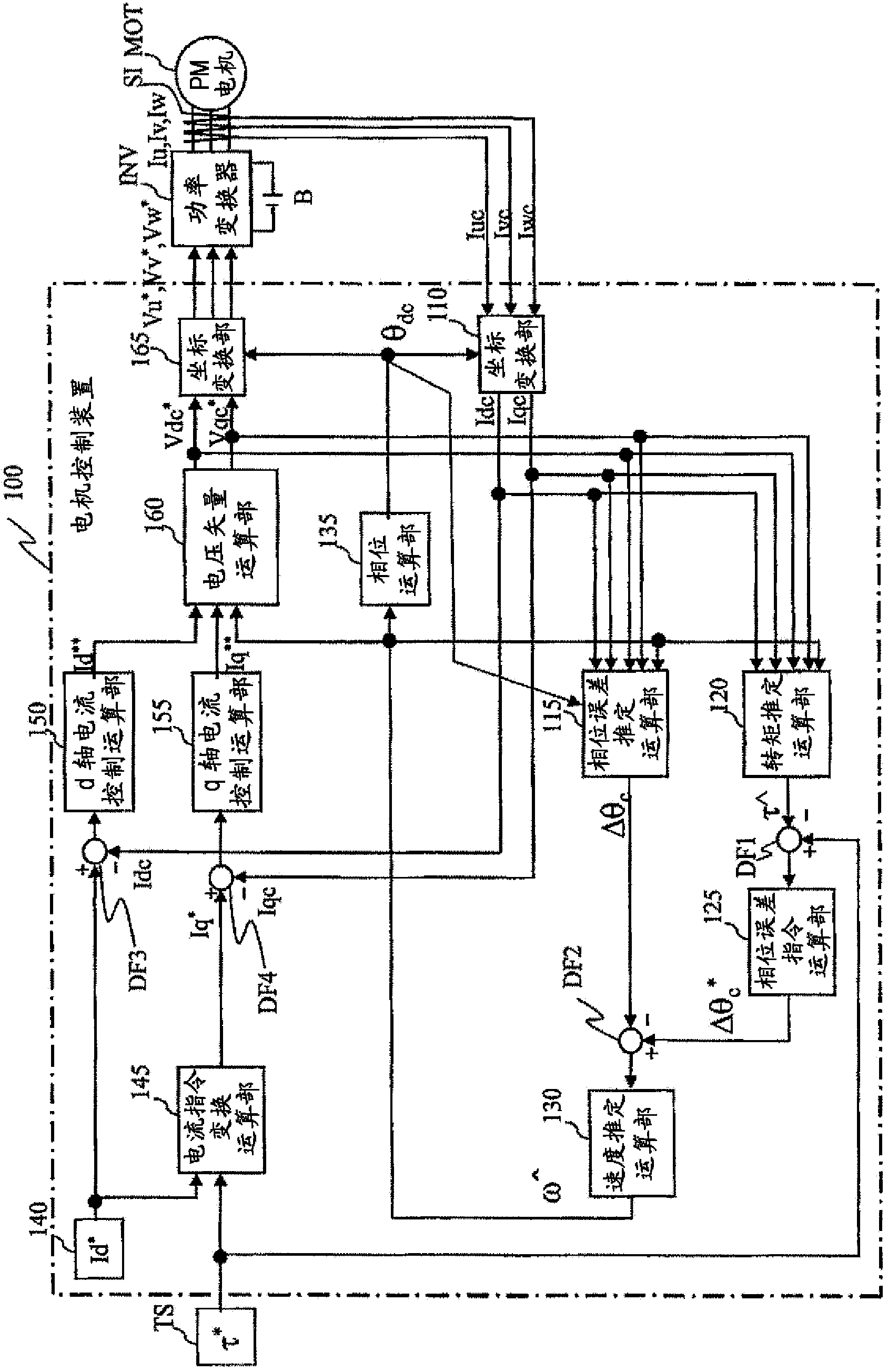

[0068] Below, use Figure 1 to Figure 6 The configuration and operation of the motor control device according to the first embodiment of the present invention will be described.

[0069] First, use figure 1 The configuration of a motor drive system using the motor control device of this embodiment will be described.

[0070] figure 1 The configuration of a motor drive system using the motor control device according to the first embodiment of the present invention will be described.

[0071] The motor drive system of the present embodiment is composed of a motor control device 100 , a power inverter INV, a permanent magnet synchronous motor (PM motor; AC motor) MOT, and a torque command setting unit TS.

[0072] A permanent magnet synchronous motor (PM motor; AC motor) MOT is composed of a rotor having permanent magnets and field coils, and a stator having armature coils. The permanent magnet synchronous motor MOT outputs a torque obtained by combining a torque component du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com