Motor torque control device and torque control system

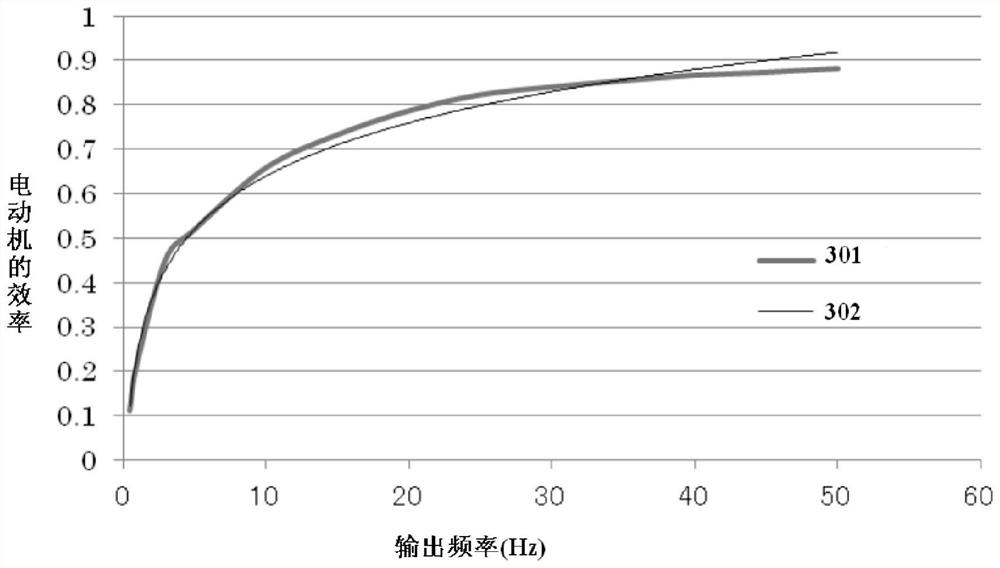

A torque control and motor technology, applied in the field of torque control devices and torque control systems, can solve problems such as complexity, deterioration of torque accuracy, large parameter errors, etc., and achieve the effect of high-precision torque control and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this application, the first embodiment provides a torque control device of an electric motor, which outputs a Q-axis current command value for torque control of the sensing motor, which is used to generate three-phase voltage values. with And, the three-phase voltage value with Control the inverter portion outputs an output current I for driving the motor u I v And i w . In this embodiment, a three-phase voltage command value is generated. with And make the inverter unit generate output current I u I v And i w A method of rotating the motor can be referred to in the prior art, and the present embodiment will not be described later.

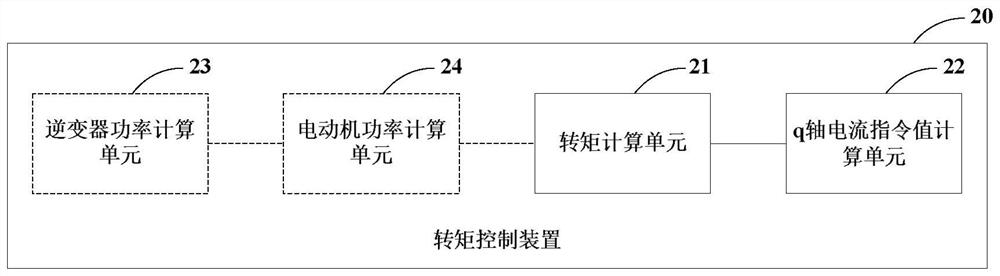

[0032]figure 2 It is a constituent diagram of the torque control device of the present embodiment, such as figure 2 As shown, the torque control device 20 can include a torque calculating unit 21 and a Q-axis current command value calculation unit 22, wherein:

[0033] The torque calculation unit 21 is based on the rotational speed of ...

Embodiment 2

[0064] The present application is provided with a torque control system of an electric motor for torque control of the motor. The torque control system includes a torque control device according to Embodiment 1.

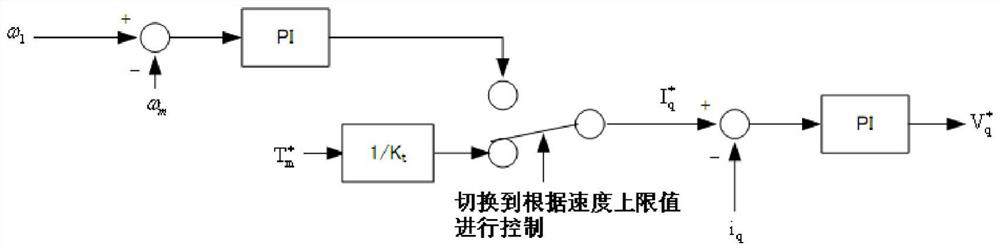

[0065] Figure 5 It is a schematic diagram of the torque control system of the present embodiment, such as Figure 5 As shown, the torque control system 500 includes a torque control device 501, a three-phase voltage calculation unit 502, an inverter portion 503, and a feedback signal generating unit 504. in:

[0066] Torque control device 501 is used to generate a Q-axis current command value Three-phase voltage calculation unit 502 based on Q-axis current command value D axis current command value Q-axis current feedback value I q And D-axis current feedback value i d , Calculate three-phase voltage value with The inverter portion 503 is in three-phase voltage value with Under the control, DC power is converted into an output current I for driving the motor 106. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com