Waste water heat energy recycling equipment

A heat recovery and waste water technology, applied in lighting and heating equipment, energy industry, filter circuit, etc., can solve the problems of high power consumption and inability to generate economic benefits, and achieve saving of treatment costs, reduction of thermal conduction effects, and reduction of management costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

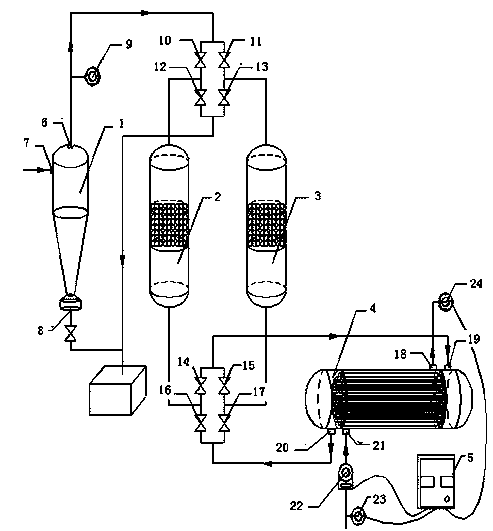

[0016] like figure 1 , 2 The shown waste water heat energy recovery equipment includes a centrifugal filter device 1, a particle filter device A2, a particle filter device B3, a heat exchange unit 4 and a cumulative calorimeter 5; the right side of the centrifugal filter device 1 has a particle filter device device A2 and particle type filter device B3, and centrifugal filter device 1 is connected with particle type filter device A2 and particle type filter device B3 through pipeline, particle type filter device A2 and particle type filter device B3 are connected with heat exchange unit 4 through pipeline, The heat exchange unit 4 is connected to a cumulative heat meter 5 through a pipeline. The top of the above-mentioned centrifugal filter device 1 is provided with a filtered water outlet 6, the upper left part is provided with a waste water inlet 7, and the bottom is provided with a filter material discharge port 8; On the pipeline between, a pressure gauge 9 is provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com