A rotary liquid supply electrospinning device

An electrospinning and liquid supply technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of unstable and mismatched liquid supply, and achieve automatic matching of consumption speed and automatic replenishment speed. Matching, lengthening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

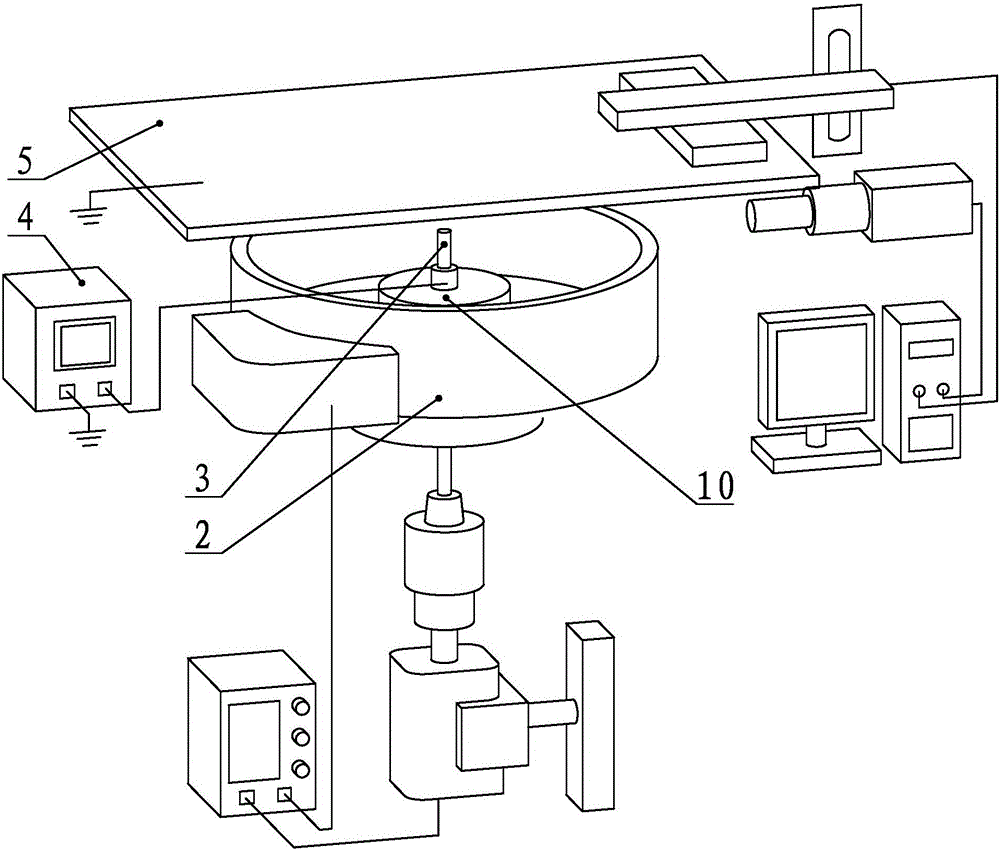

[0026] As a specific example, such as figure 1 Shown, a kind of rotating liquid electrospinning device of the present invention comprises solution tank 2, rotating table 10, probe 3, first driving device and second driving device, collecting device 5 and high-voltage power supply 4, and described rotating The table 10 is arranged on the inner bottom surface of the solution tank 2, and the solution tank 2 is made of insulating material, and the upper end surface of the rotary table 10 is made of a material with a large surface roughness. The cross-section of the turntable 10 is circular, and the diameter of the circle is 1 cm to 5 cm. The rotary table 10 is arranged on the inner bottom surface of the solution tank 2, the rotary table 10 is provided with a central through hole, the bottom of the probe 3 passes through the central through hole, and the probe 3 passes through the solution tank 2. The connecting piece is connected, and the bottom of the solution tank 2 is provided...

Embodiment 2

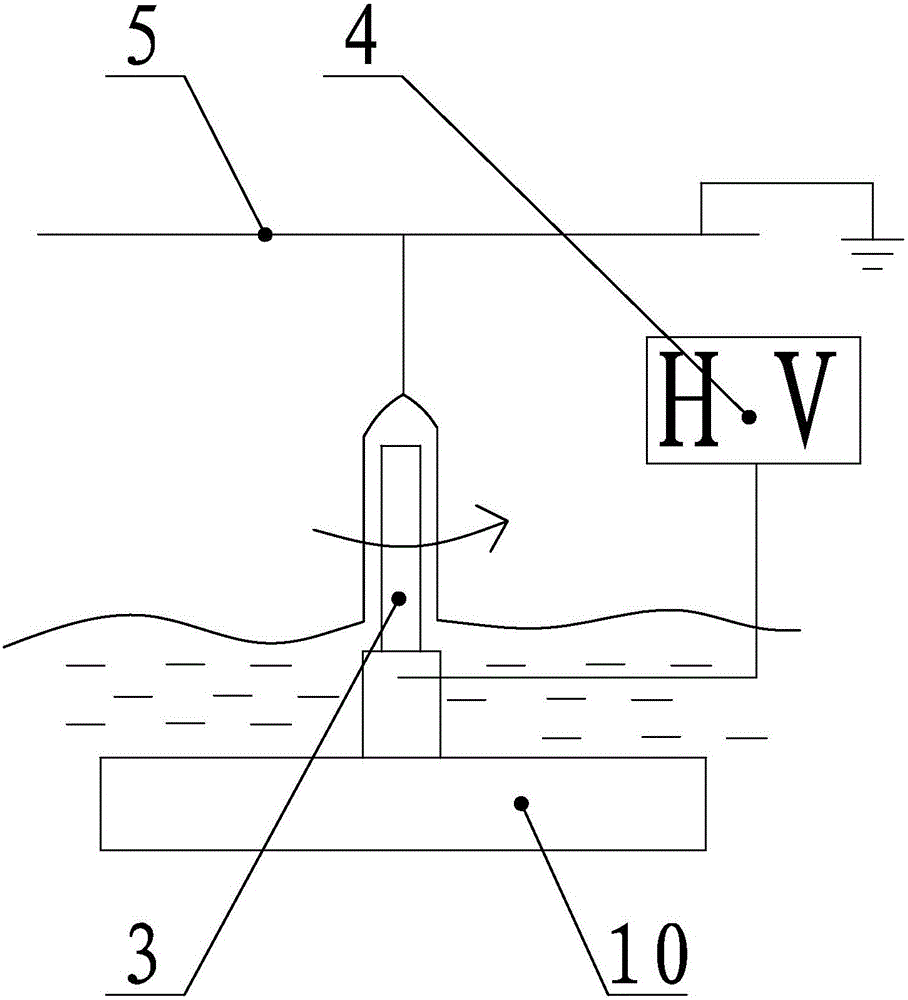

[0046] refer to image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that the power supply mode is different, and the power supply mode of connecting the positive plate of the power supply on the collecting plate is beneficial to the spraying of some conductive solutions. The electric field connection method in this embodiment 2 is: the collecting plate is electrically connected to the output end of the high-voltage power supply, and the guide rail of the probe 3 is grounded

[0047] The way of liquid supply in Embodiment 2 is: the rotary table 10 is stationary, and the probe 3 rotates, such as image 3 shown.

[0048] See embodiment 1 for other assembly relations in detail.

Embodiment 3

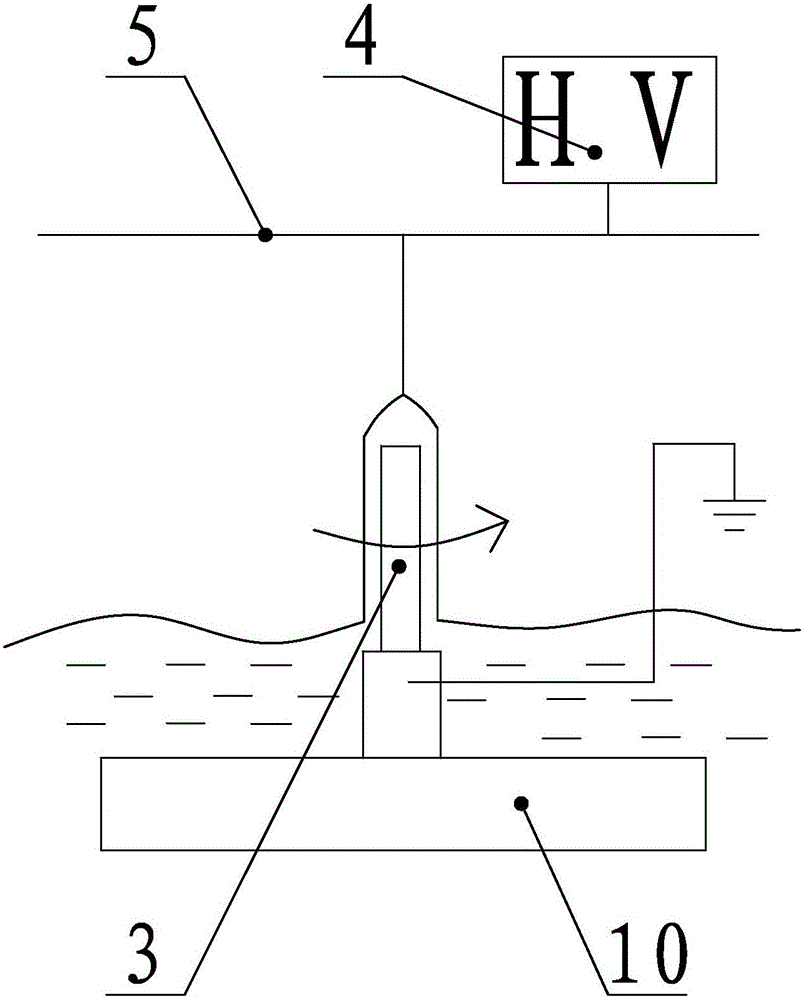

[0050] refer to Figure 4 As shown, the electric field connection method of Embodiment 3 is as follows: the guide rail of the probe 3 is electrically connected to the output end of the high-voltage power supply, and the collecting plate is grounded.

[0051] The liquid supply mode of the present embodiment is: the probe 3 is stationary, and the turntable 10 rotates, such as Figure 4 shown.

[0052] See embodiment 1 for other assembly relations in detail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com