Fermentation method for natural perfume gamma-decalactone

A technology of natural flavor and fermentation method, applied in the directions of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problem of incomplete conversion of castor oil, long period of biotransformation of castor oil, and efficiency of γ-decalactone biosynthesis. Low problems, to achieve the effect of lifting inhibition, improving conversion rate and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

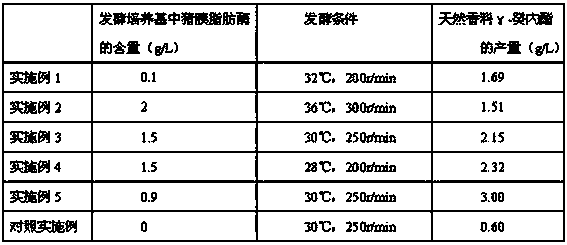

Examples

preparation example Construction

[0040] (2) Preparation of seed liquid for fermentation

[0041] Use the sterilized inoculation shovel to inoculate the slant bacteria with a size of 1cm*2cm into a 500mL shaker flask with 50mL seed medium, place it on a shaking table and control the speed at 200-300r / min, and the temperature is 28 Cultivate at ℃ for 24h to obtain seed solution;

[0042] Described seed culture medium is calculated by every liter, by the castor oil of 1.0g, the glucose of 20g, the (NH 4 ) 2 HPO 4 , 3.2g of KH 2 PO 4 , 1.5g of K 2 HPO 4 ·3H 2 O, 4.0g of MgSO 4 ·7H 2 O, 3.0g of NaCl, 15.0g of yeast extract and the remainder of water, the pH is natural.

[0043] 2. The content of γ-decalactone in the fermented liquid obtained in each embodiment of the present invention adopts the gas phase analysis method, and the instrument used is a gas chromatograph, namely Agilent 6890N, produced by Agilent Technology Co., Ltd. of the United States, and the chromatographic column is HP-5 Column (30mX...

Embodiment 1

[0051] Shake flask fermentation medium is calculated per liter, and it consists of 20g of castor oil, 10g of glucose, 10.0g of yeast extract, 0.1g of (NH 4 ) 2 HPO 4 , 0.5g of KH 2 PO 4 , 2.5g of K 2 HPO 4 ·3H 2 O, 1.2g of MgSO 4 ·7H 2 O, 7.0g of NaCl, 0.1g of porcine pancreatic lipase and the rest of the water, the pH is natural.

[0052] After sterilizing the above-mentioned shake flask containing the shake flask fermentation medium at 121°C for 20 minutes, insert 2% seed solution in a sterile room at a temperature of 25°C, the shake flask is 250mL, and the liquid volume is 20%, and then carried out fermentation culture on a shaker at a controlled temperature of 32°C and a rotational speed of 200r / min, and the fermentation ended after 30 hours of constant temperature cultivation.

[0053] After the fermentation is finished, it is calculated according to the volume ratio, that is, the ratio of fermented liquid: butyl acetate is 1:1. After adding butyl acetate to the ...

Embodiment 2

[0056] Shake flask fermentation medium is calculated per liter, and it consists of castor oil of 10g, glucose of 20g, yeast extract of 20g, (NH 4 ) 2 HPO 4 , 3.0g of KH 2 PO 4 , 1.2g of K 2 HPO 4 ·3H 2 O, 3.0g of MgSO 4 ·7H 2 O, the NaCl of 3.5g, the lipase of 2.0g and the water of remainder, pH is natural.

[0057] After sterilizing the above-mentioned shake flask containing the shake flask fermentation medium at 121°C for 20 minutes, insert 2% seed solution in a sterile room at a temperature of 25°C, the shake flask is 250 mL, and the liquid The amount is 20%, and then on a shaker, the temperature is controlled at 36°C, the rotation speed is 300r / min, and the fermentation is completed after 30 hours of constant temperature cultivation.

[0058] After the fermentation is finished, it is calculated according to the volume ratio, that is, the ratio of fermented liquid: butyl acetate is 1:1. After adding butyl acetate to the obtained fermented liquid, rotate and shake f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com