Glue material supply apparatus

A technology of a supply device and an air supply device, which is applied to the device for coating liquid on the surface, coating, etc., which can solve the problem that the rhythm of the glue flow can not be controlled, it is difficult to ensure the uniformity of glue brushing, and the operation is not flexible and other problems, to achieve the effects of widely popularizing and applying, improving the efficiency of glue brushing, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

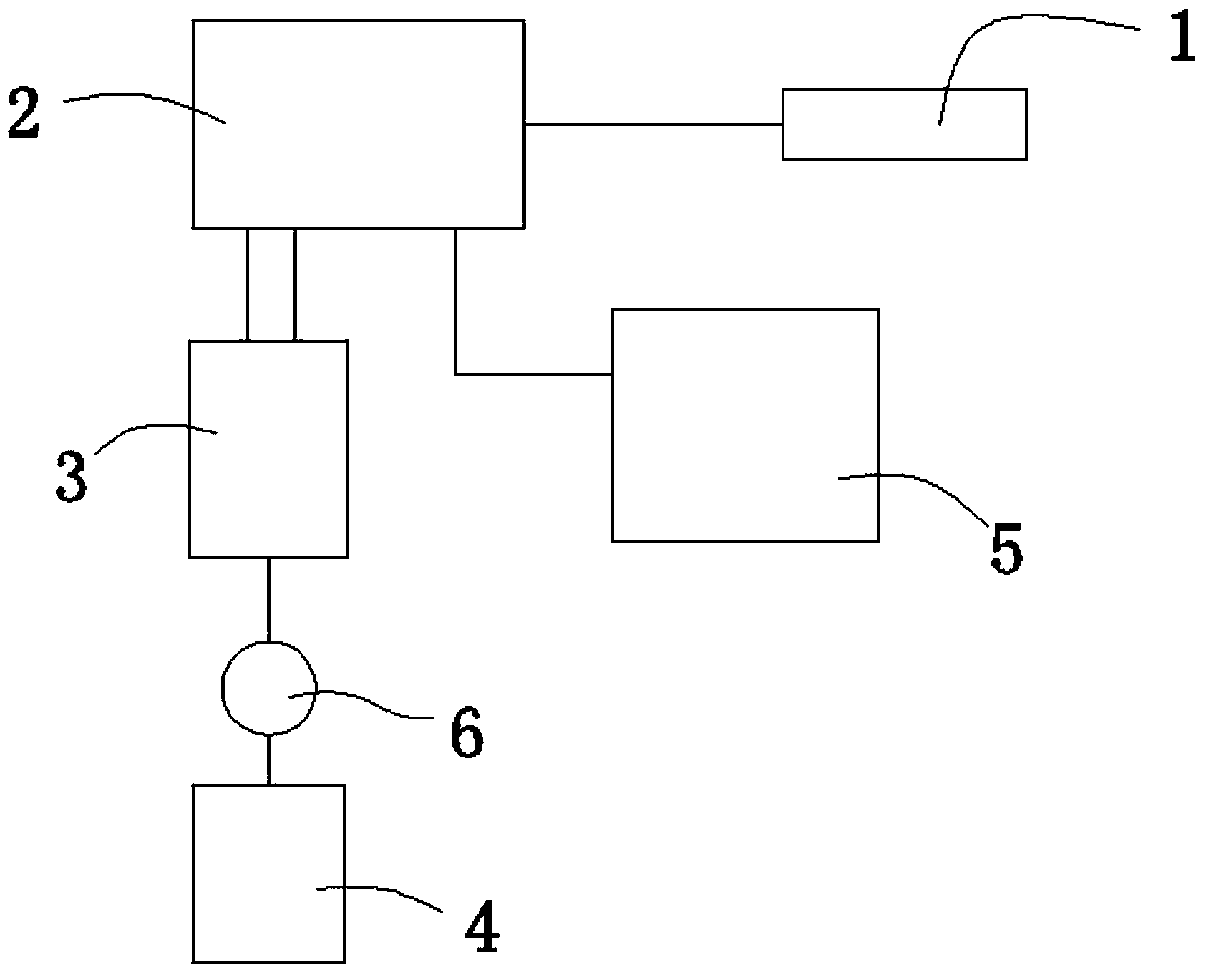

[0015] Example: see figure 1 with figure 2 , a glue supply device provided in this embodiment, which includes a glue brushing part 1, a glue discharge control mechanism 2, a control switch 3 and a high-pressure air supply device 4, the glue brush part 1, a glue discharge control mechanism 2, a control The switch 3 and the high-pressure gas supply device 4 are connected in sequence.

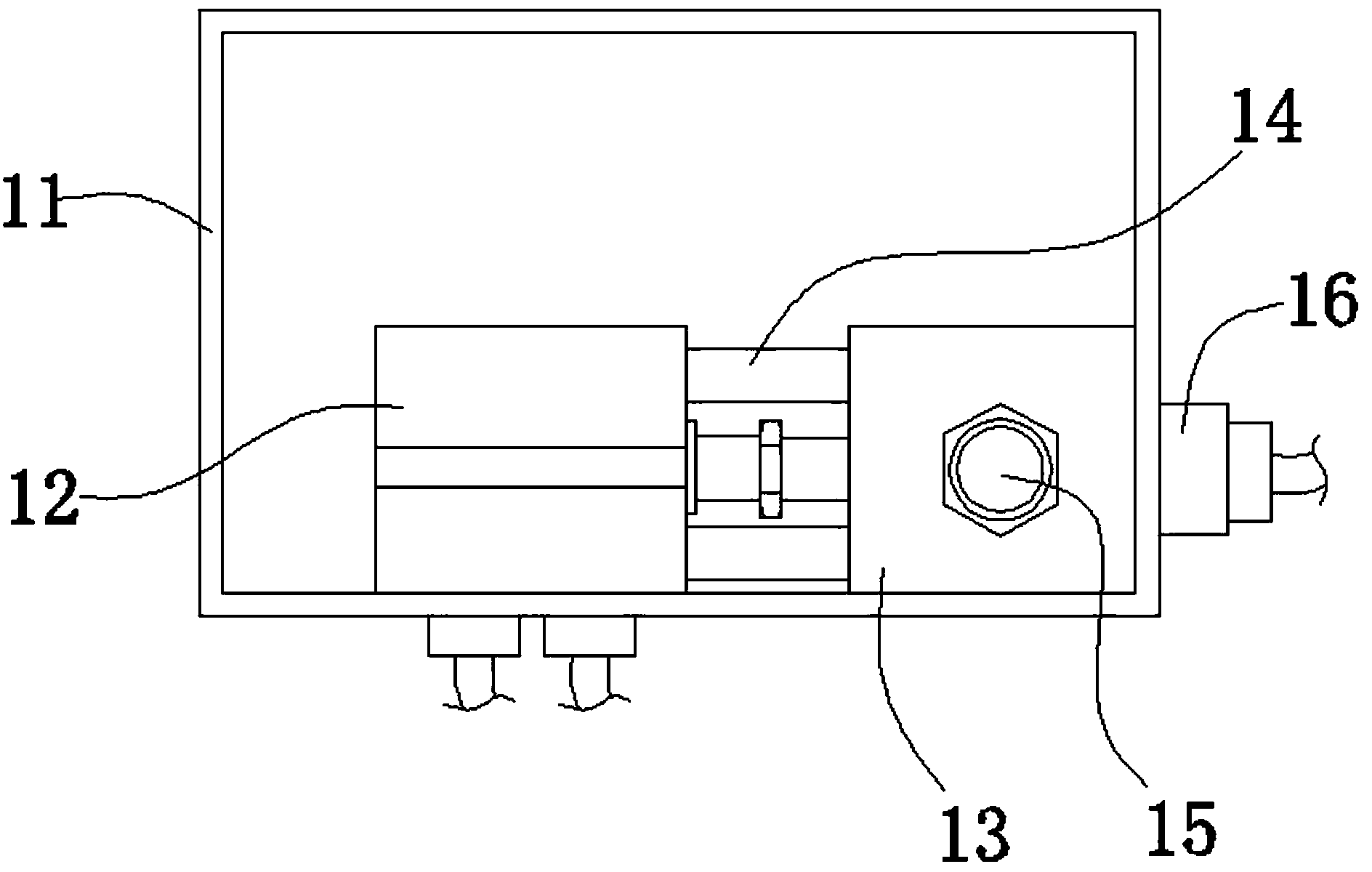

[0016] The glue-discharging control mechanism 2 includes a box body 11 and a cylinder 12 and a pneumatic switch 13 arranged in the box body 11. The cylinder body of the cylinder 12 is fixed with the housing of the pneumatic switch 13 through a fixed rod 14. The piston rod of the cylinder 12 is connected to the switch part of the pneumatic switch 13, and the pneumatic switch 13 is provided with a glue inlet port 15 for connecting with the glue brushing machine 5 and a glue inlet port 15 for connecting with the glue brushing part 1. Glue port 16.

[0017] A pressure regulating valve is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com