Multi-way valve body fluid casting hydraulic part

A technology of multi-way valves and hydraulic parts, which is applied in the direction of valve details, valve devices, valve housing structures, etc., can solve problems such as inability to make stable connections and inability to control the flow of flow channels, so as to facilitate installation and disassembly, prevent waste, and meet The effect of using demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

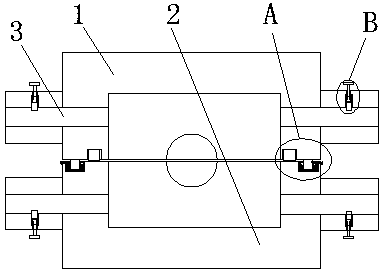

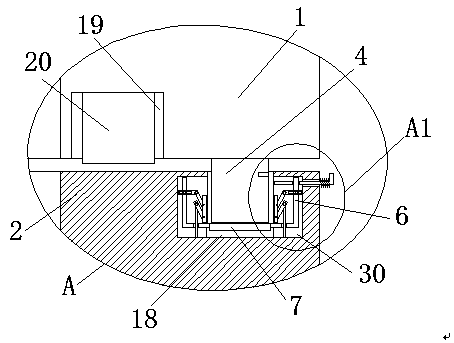

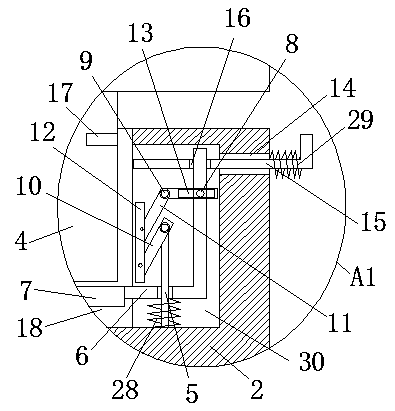

[0026] refer to Figure 1-5 , a multi-way valve body liquid casting hydraulic parts, including an upper valve body 1, a lower valve body 2 is arranged below the upper valve body 1, and a plurality of flow channels 3 are arranged on the upper valve body 1 and the lower valve body 2 , the top side of the lower valve body 2 is provided with two installation grooves 18, the bottom side of the upper valve body 1 is fixedly installed with two installation columns 4, and the bottom ends of the two installation columns 4 respectively extend into the two installation grooves 18, Both side inner walls of the installation groove 18 are provided with grooves 30, and the bottom inner walls of the two grooves 30 are fixedly equipped with L-shaped rotating posts 5, and the two L-shaped rotating posts 5 are slidingly sleeved with L-shaped rotating posts. Sliding column 6, one end of the two L-shaped sliding columns 6 that are close to each other extends into the installation groove 18 and is ...

Embodiment 2

[0035] refer to Figure 1-5 , a multi-way valve body liquid casting hydraulic parts, including an upper valve body 1, a lower valve body 2 is arranged below the upper valve body 1, and a plurality of flow channels 3 are arranged on the upper valve body 1 and the lower valve body 2 , the top side of the lower valve body 2 is provided with two installation grooves 18, and the bottom side of the upper valve body 1 is fixedly welded with two installation columns 4, and the bottom ends of the two installation columns 4 respectively extend into the two installation grooves 18, Both sides of the installation groove 18 are provided with grooves 30 on the inner walls of both sides, and the bottom inner walls of the two grooves 30 are fixedly welded with L-shaped rotating columns 5, and the two L-shaped rotating columns 5 are slidingly sleeved with L-shaped rotating columns 5. Sliding column 6, the ends of the two L-shaped sliding columns 6 that are close to each other extend into the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com