Melt-blown nonwoven fabric and use thereof

A technology of melt-blown non-woven fabrics and thermoplastic resins, which is applied in non-woven fabrics, textiles, papermaking, textiles, etc., to achieve high sound absorption, eliminate dust, and achieve lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

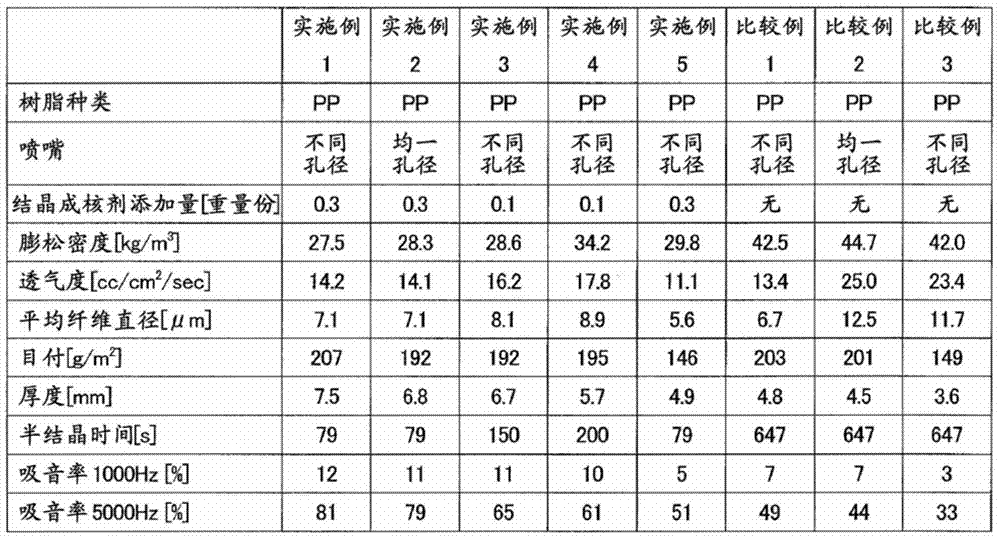

[0097] As a thermoplastic resin, a propylene homopolymer [MFR=1550g / 10min (measured at a temperature of 230°C under a load of 2.16kg in accordance with ASTM D1238), hereinafter referred to as PP] was used as a crystal nucleating agent to add 100 parts by weight to PP. A thermoplastic resin composition was obtained using 0.3 parts by weight of a phosphoric acid-based nucleating agent (NA11 manufactured by Adeka Corporation, hereinafter referred to as nucleating agent A). Extrude at 300°C using a melt-blown nonwoven fabric manufacturing device equipped with five small-diameter nozzles with a nozzle diameter of 0.15 mm and one large-diameter nozzle with a nozzle diameter of 0.6 mm as the minimum repeating unit for melt-blown spinning nozzles Thermoplastic resin composition, with heated air (300°C, 350Nm) blown from both sides of the spinning nozzle 3 / m / hour) after thinning and solidification, the fiber was collected at a distance of 40cm from the spinning nozzle, and the target ...

Embodiment 2

[0099] A melt-blown nonwoven fabric was obtained by the same method as that described in Example 1 except that the nozzle was changed to a spinning nozzle for melt-blown having uniform holes with a hole diameter of 0.6 mm. Table 1 shows the measurement results of the obtained meltblown nonwoven fabric.

Embodiment 3

[0101] Using the spinning nozzle for meltblowing used in Example 1, except that the addition amount of the nucleating agent A was 0.1 parts by weight relative to 100 parts by weight of PP, it was carried out in the same manner as in Example 1, and a meltblown nonwoven fabric was obtained. cloth. Table 1 shows the measurement results of the obtained meltblown nonwoven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystallization time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com