Epoxy resin compound and radiant heat circuit board using the same

A technology of epoxy resin and epoxy adduct, which can be applied to circuits, printed circuits, printed circuits, etc., can solve the problems of reducing the reliability of heating devices, failing to work normally, and increasing the temperature of circuit boards, and achieves improvement. Improved solubility, precipitation, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0073] Hereinafter, the present disclosure will be described in more detail through embodiments.

[0074] The thermal conductivity was measured by an abnormal heat conduction scheme using a thermal conductivity meter LFA447 manufactured by NETZSCH.

[0075] The epoxy resin composition is coated on the Al substrate and cured, and then the Al substrate is bent at 180 degrees and returned to the original position, and the peeling performance of Al is represented by the delamination degree (delmaination degree) of the epoxy resin composition . Record when the degree of delamination is less than 0.2 cm. Record when the degree of delamination is in the range of 0.2 cm to 1 cm. Record when the degree of delamination is 1 cm or greater.

Embodiment approach 1

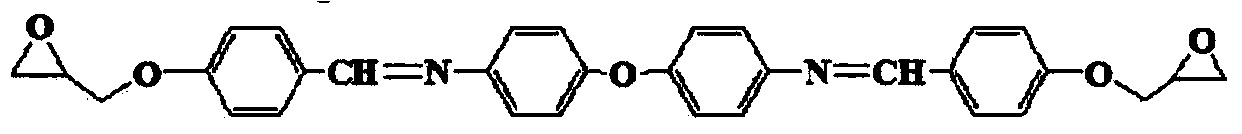

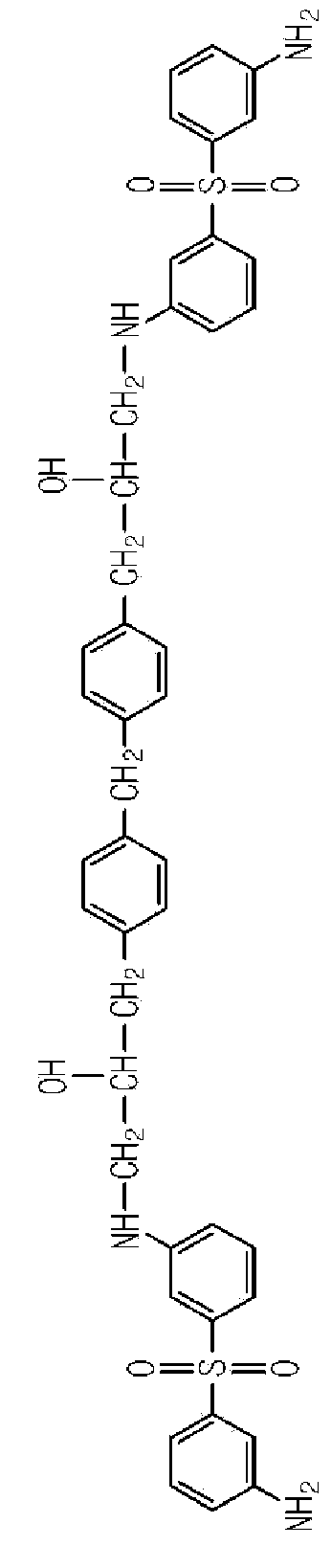

[0077] 3w% bisphenol F, 3w% o-cresol-novolak, 2w% 4,4'oxobis(N-(4-(epoxy-2-ylmethoxy) Benzylidene)aniline (4,4'oxybis(N-(4-(oxiran-2-ylmethoxy)benzylidene)-aniline)), 2w% NC-3000H epoxy resin (Nippon Kayaku co.,Ltd), 2w% of DAS curing agent, 2w% of DAS curing accelerator, 0.5w% of BYK-W980 and 2.5w% of the epoxy adduct represented in Chemical Formula 2 were mixed with each other and stirred at a temperature of 40°C for 10 minutes Thereafter, 85w% of alumina inorganic filler was introduced into the mixture, and stirred at room temperature for 20 minutes to 30 minutes to prepare the crystalline epoxy resin composition of Embodiment 1.

Embodiment approach 2

[0079] 3w% of bisphenol F, 2w% of 4,4'oxobis(N-(4-(epoxy-2-ylmethoxy)benzylidene)aniline, 1.5w% of NC-3000H ring Oxygen resin (Nippon Kayaku co., Ltd), 1w% of DAS curing agent, 1.5w% of the epoxy adduct represented in Chemical Formula 2 and 0.5w% of BYK-W980 were mixed with each other and heated at a temperature of 40°C Stir for 10 minutes. Thereafter, introduce 88w% alumina inorganic filler into the mixture, and stir at room temperature for 20 to 30 minutes to prepare the crystalline epoxy resin composition of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com