A kind of interconnected flexible solar cell and its manufacturing method

A technology of solar cells and flexible cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complicated process operation and difficult realization of ohmic contact, and achieve the effects of increasing light-receiving area, enhancing conductive contact, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

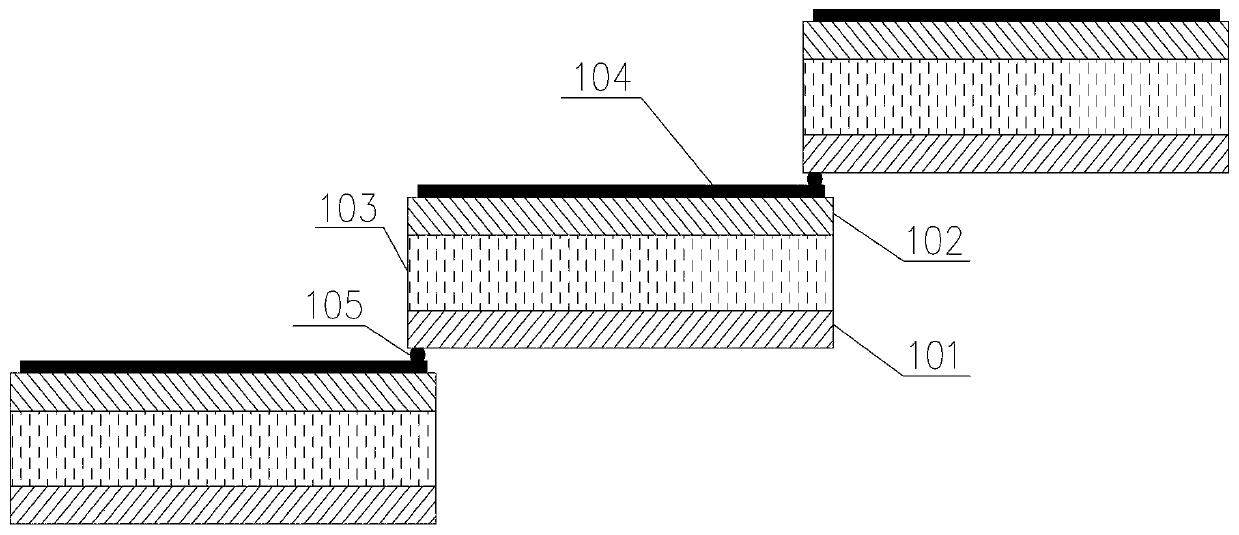

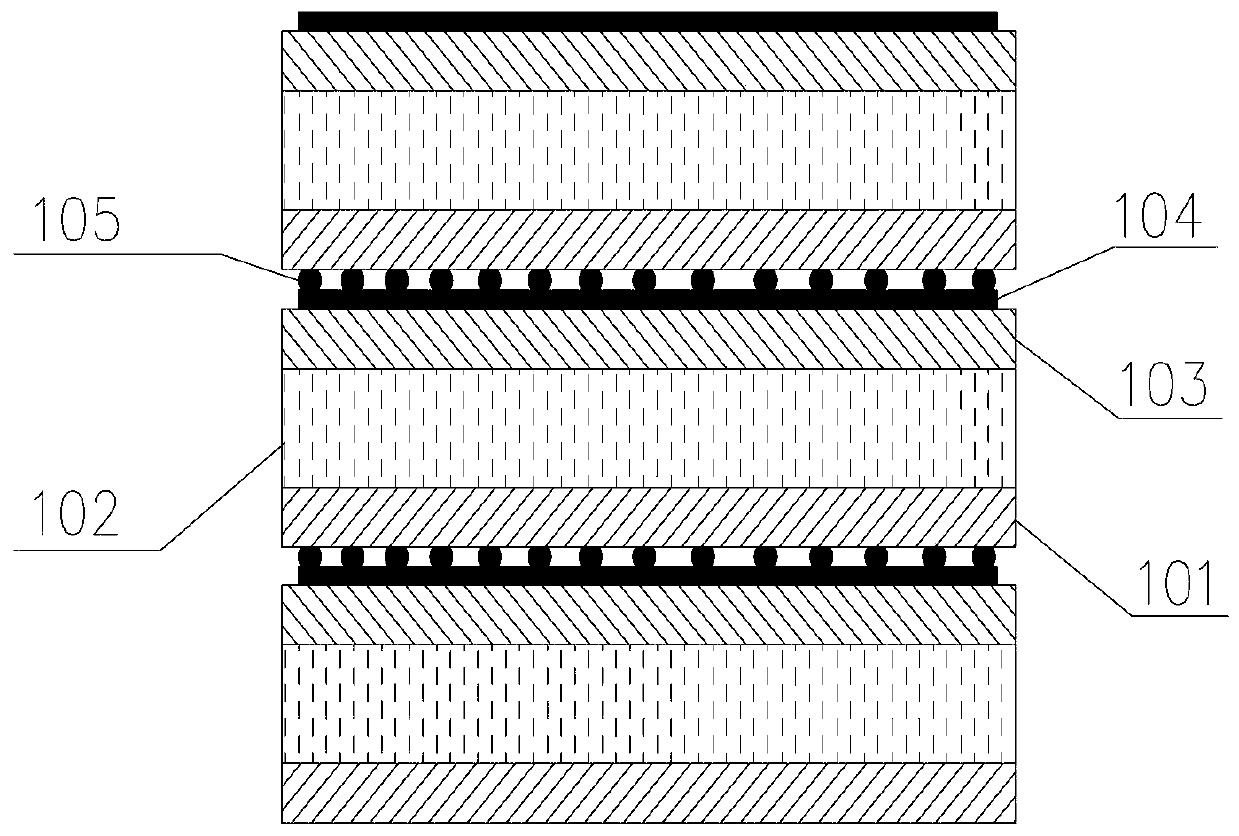

[0048] see figure 1 , figure 2 with image 3 , an interconnected flexible solar cell, including three flexible solar cell units, the flexible solar cell unit includes a flexible cell substrate 101, a semiconductor material layer 103 and a light-receiving layer 102, and the light-receiving layer 102 is provided with a conductive bus bar 104. Among two adjacent flexible solar battery units, the side of the light-receiving layer 102 of one flexible solar battery unit overlaps the side of the flexible battery substrate 101 of the other flexible solar battery unit, and the light-receiving layer 102 on the light-receiving layer 102 A conductive connection structure 105 is provided between the conductive bus bar 104 and the flexible battery substrate 101 .

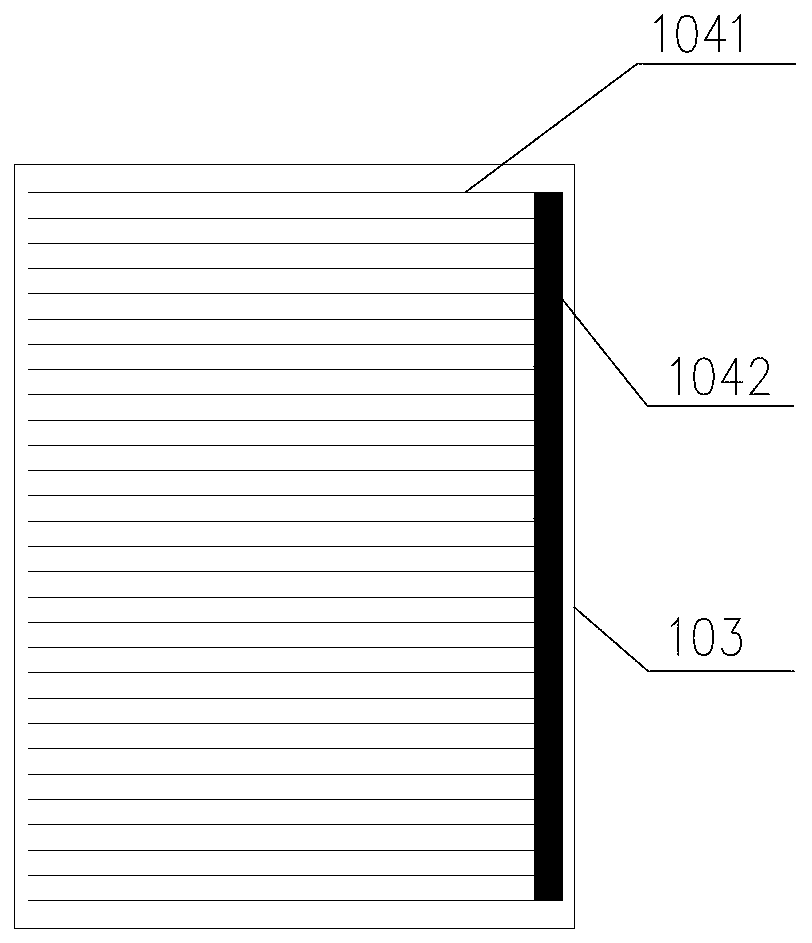

[0049] In this embodiment, the conductive bus bar 104 is a comb-shaped structure, including a thin grid line 1041 and a main grid line 1042, one end of the thin grid line 1041 intersects with the main grid line 1042 at 90 degr...

Embodiment 2

[0054] The same or similar technical content in this embodiment as in Embodiment 1 will not be described one by one in this embodiment.

[0055] In this embodiment, the conductive bus bar 104 is a comb-like structure, including thin grid lines 1041 and main grid lines 1042. The thin grid lines 1041 and main grid lines 1042 intersect at an angle of 45 degrees. The line 1041 includes at least two parallel thin grid lines, the width of the thin grid lines 1041 is 0.2 mm, and the parallel thin grid lines are 3 mm apart from each other, the width of the main grid lines 1042 is 4 mm, and the distance between the edges of the main grid lines 1042 and The side portion of the parallel light-receiving layer 102 is 10 mm, and the material of the conductive bus bar 104 in this embodiment is silver.

[0056] In this embodiment, the light-receiving layer 102 of one flexible solar battery unit overlaps the flexible battery substrate 101 of another flexible solar battery unit by 15 mm.

Embodiment 3

[0058] The same or similar technical content in this embodiment as in Embodiment 1 will not be described one by one in this embodiment.

[0059] In this embodiment, the structure of the flexible solar battery unit is the same as that in Embodiment 1; in this embodiment, the conductive connection structure 105 is a row of conductive metal fleece parallel to the flexible battery substrate. In this embodiment, the The conductive metal suede is a suede made of metal copper particles, the diameter of the metal copper particles is 10 microns, and the width of the metal suede is 15 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com