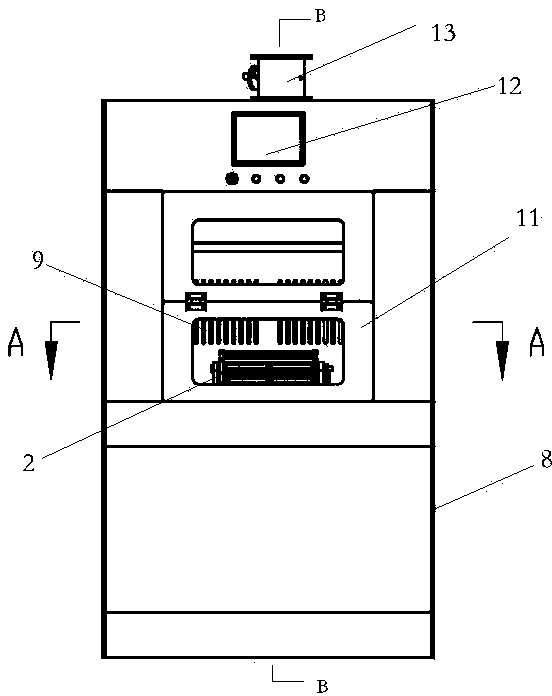

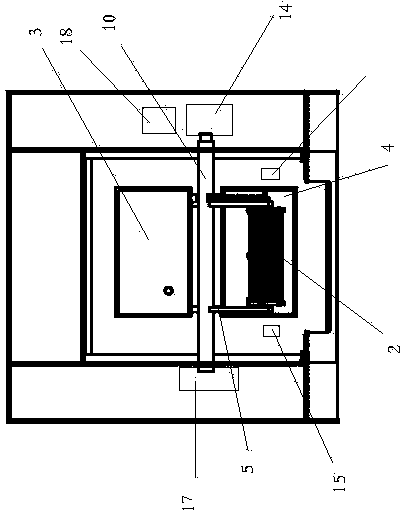

Double-tank groove etching machine

An etching machine and groove technology, which is applied in the field of electronic component etching processing devices, can solve the problems of incomplete cleaning, slow corrosion speed in large areas, uneven etching surface, etc., and achieve simple control, improved cleaning effect, and uniform cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

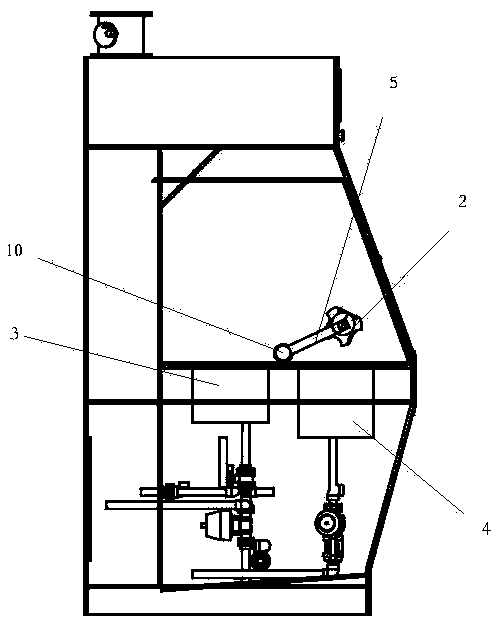

Examples

Embodiment 2

[0037] Example 2, such as Figure 6 As shown, the only difference between this embodiment and Embodiment 1 is that the bottom surface 24 of the pickling tank is an arc surface adapted to the outer surface of the rotating basket. The pickling tank 3 is provided with a cooling coil 25, and the cooling coil 25 is connected with a cooling liquid circulation device. The first servo motor, the second servo motor, and the third drive motor are all arranged below the top surface of the cleaning tank and the washing tank and are isolated from the cleaning tank and the washing tank by a sealing plate, so that the motors can be corroded by acid liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com