Wafer cleaning machine

A cleaning machine and strip technology, applied in the field of cleaning machines, can solve the problems of low automation, unclean cleaning and difficult separation of wafers, etc., and achieve the effects of reducing labor costs, improving product yield, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

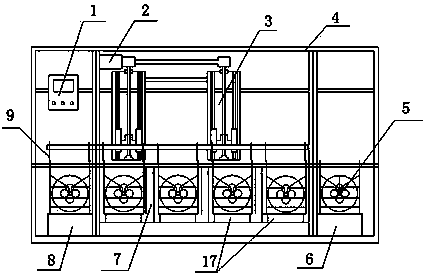

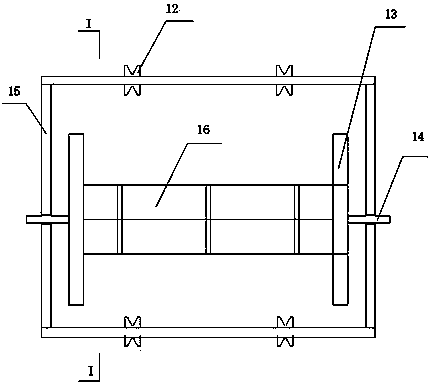

[0023] like figure 1 and figure 2 As shown, a strip cleaning machine includes a frame 4, and the lower part of the frame 4 is sequentially provided with a loading table 6, a cleaning tank 7, a blanking table 8 and a driving device from right to left, The bottom of the cleaning tank 7 is provided with an ultrasonic vibrating plate 17, the cleaning tank 7 is provided with a rotary cleaning device 5, and the rotary cleaning device 5 is driven to rotate by a driving device. Hook manipulator 3, the deceleration motor B10 that drives single-arm multi-hook manipulator 3 to move horizontally and the deceleration motor C2 that drives single-arm multi-hook manipulator 3 to move up and down, in the present embodiment, deceleration motor B10, deceleration motor C2 and deceleration motor A11 are erected on On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com