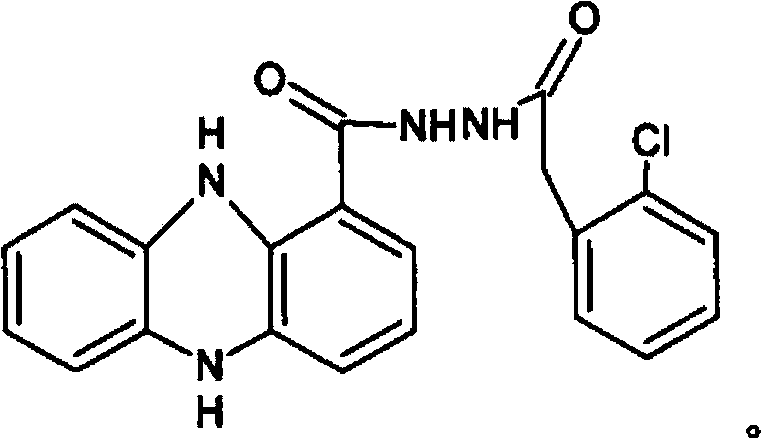

Biological bactericide and preparation method thereof

A technology of biological fungicides and strains is applied in the field of microorganisms to achieve the effects of reducing foam, simple process flow and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

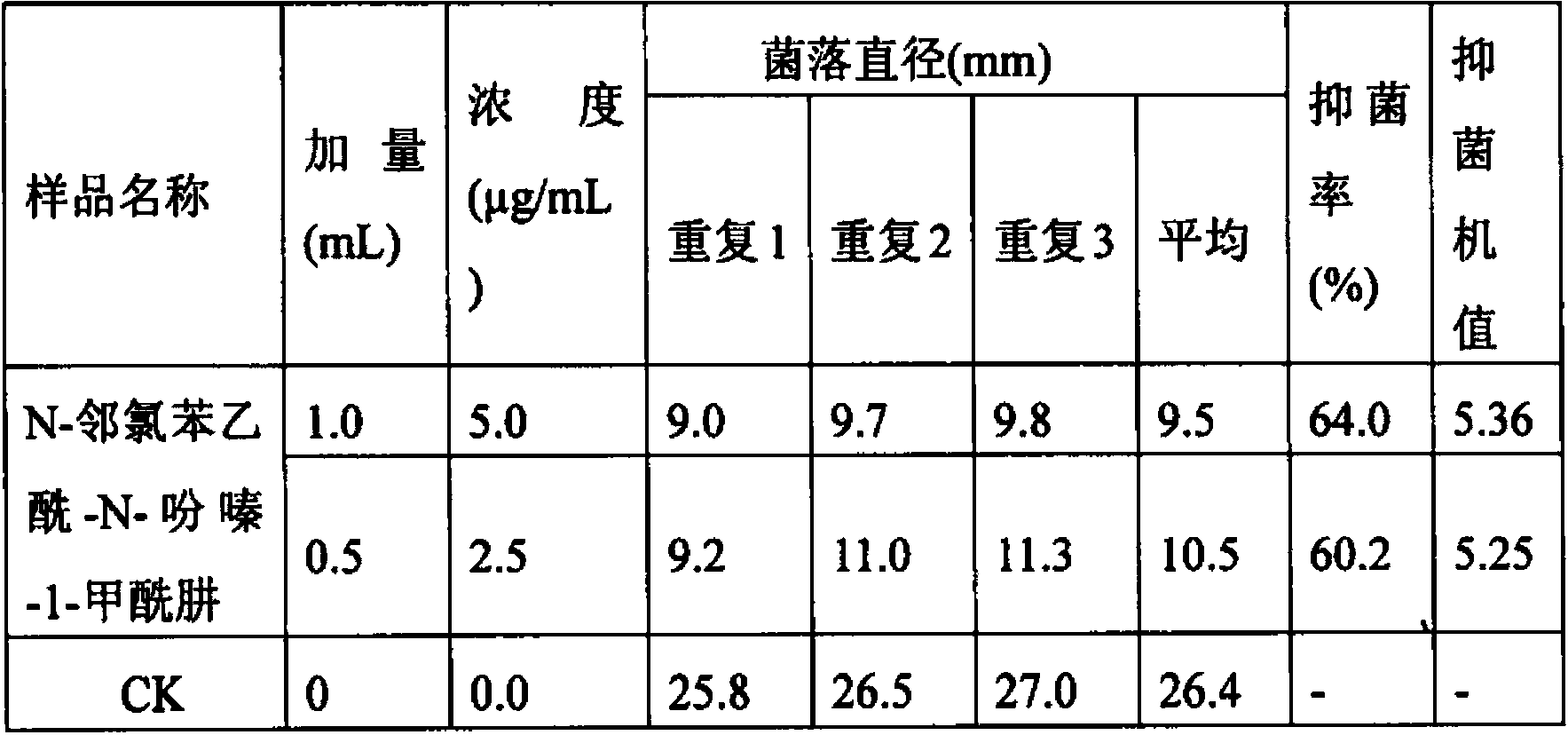

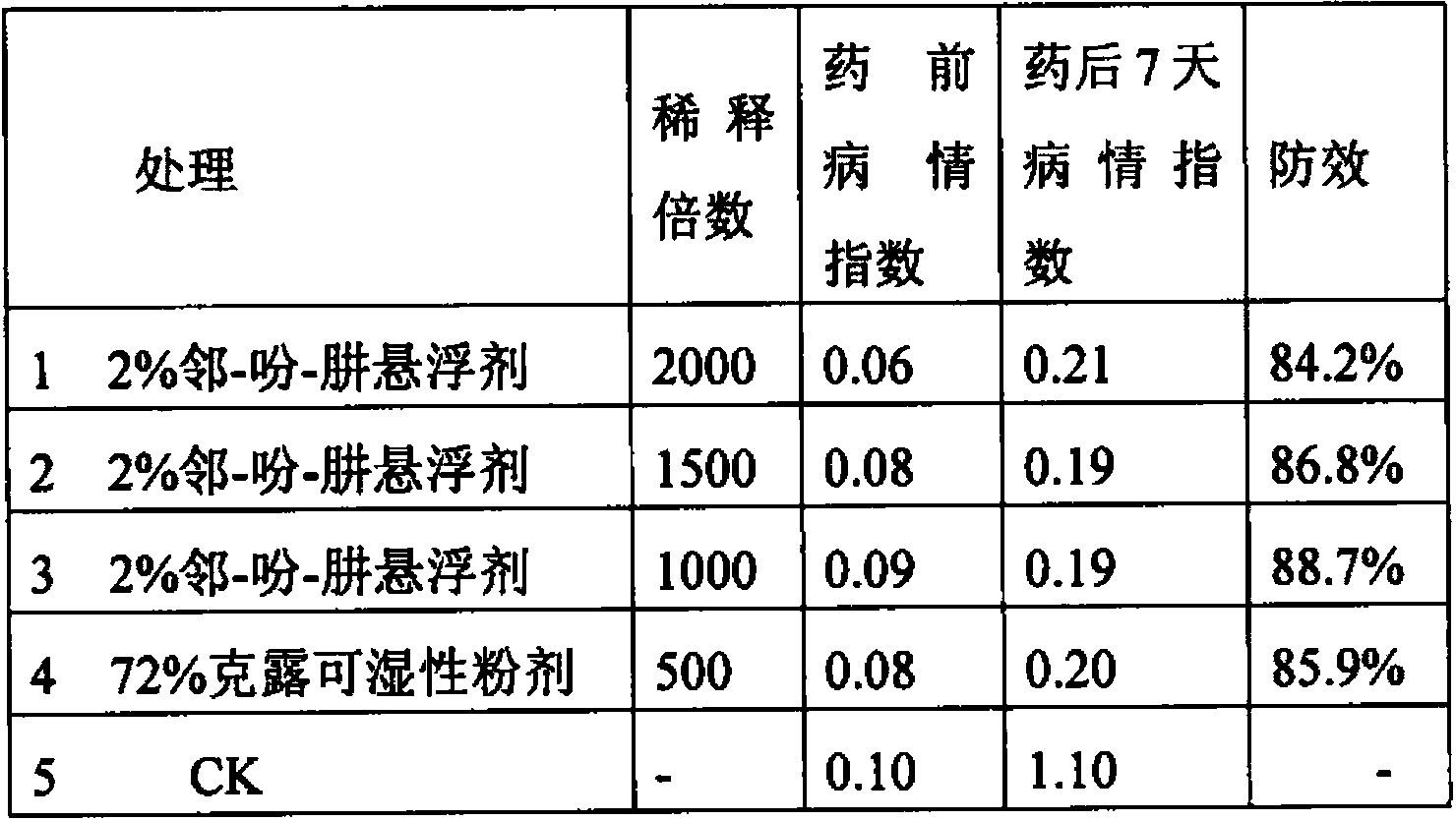

Examples

Embodiment 1

[0026] Use 10 1000mL Erlenmeyer flasks, each filled with 300mL medium A (2.0% glucose, 3.0% peptone, 0.5% beef extract, 0.35% magnesium sulfate and 0.3% potassium dihydrogen phosphate), sterilize at 120°C for 30 minutes, after cooling The activated Pseudomonas chloropinus strain SN36 bacteria solution was inoculated, placed at a temperature of 30° C., and shaken for 18 hours. Inoculate the cultured strain solution into 50L sterilized medium B, 2% viscous agent (dextrin, or xanthan gum, or sodium alginate, or carboxymethyl cellulose) according to the inoculation amount of 5%-10%. Sodium (CMC)) in a 100L fermenter, (medium B: starch 2.0%, lactose 1.0%, sucrose 1.0%, glycerin 0.5%, glucose 1.0%, peptone 1.0%, peanut powder 5.0%, soybean powder hydrolyzate 2.0% %, biological nitrogen 3.0%, potassium dihydrogen phosphate 0.1%, sodium chloride 0.5% and iron sulfate 0.5%). At a temperature of 28°C 2-30°C, after 8-15 hours of aeration and stirring fermentation, the medium C (medium C...

Embodiment 2

[0031] Use 12 1000mL Erlenmeyer flasks, each containing 300mL medium A (glucose 2.0%, peptone 3.0%, beef extract 0.5%, magnesium sulfate 0.35%, and potassium dihydrogen phosphate 0.3%), sterilize at 120°C for 30 minutes, cool Afterwards, inoculate the activated Pseudomonas chloropinus strain SN36 bacterium solution, place it at a temperature of 30° C., and culture it in a shaker flask for 18 hours. Inoculate the cultured strain solution into 50L sterilized medium B, 5% viscous agent (agar, or soluble starch, or sodium alginate, or sodium carboxymethylcellulose ( CMC)) in a 100L fermenter, (medium B: starch 3.0%, lactose 2.0%, glycerin 0.6%, waste molasses 3.0%, glucose 1.0%, peptone 0.1%, peanut powder hydrolyzate 5.0%, soybean powder hydrolyzate 2.0%, biological nitrogen 2.0%, potassium dihydrogen phosphate 0.1%, sodium chloride 0.5% and iron sulfate 0.5%), at a temperature of 28°C-30°C, after aeration and stirring for 10-15 hours, with 0.5-2.0 The speed of L / h is continuous...

Embodiment 3

[0036] Use 15 1000mL Erlenmeyer flasks, each filled with 300mL medium A (3.0% glucose, 3.0% peptone, 0.8% beef extract, 0.35% magnesium sulfate, 0.3% potassium dihydrogen phosphate), sterilize at 120 for 30 minutes, and inoculate after cooling The activated bacterial liquid of Pseudomonas chloropinus strain SN36 was placed at a temperature of 30° C. and shaken for 18 hours. Inoculate the cultured strain solution into a 100L fermenter with 50L sterile medium B and 8% viscous agent (soluble starch, or dextrin, or sodium alginate) at an inoculum size of 5%-20%, ( Medium B: starch 2.0%, lactose 2.5%, glycerin 1.5%, waste molasses 3.0%, glucose 1.0%, peptone 0.5%, peanut powder 5.0%, soybean powder 2.0%, biological nitrogen 4.0%, potassium dihydrogen phosphate 0.1 %, sodium chloride 0.5% and iron sulfate 0.5%), at a temperature of 28°C-30°C, after 10-15 hours of aeration and stirring fermentation, medium C (medium C: sucrose, molasses 2.0% , Glycerin 1.0%, Glucose 2.0%, Lactose 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com