White dust suppressant and preparation method and application thereof

A dust suppressant, white technology, applied in the field of white dust suppressant and its preparation, can solve the problems of poor film-forming effect, poor hardness and toughness, inconvenient management of coal yards, etc., achieve low cost, simple construction, The effect of facilitating material stacking management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

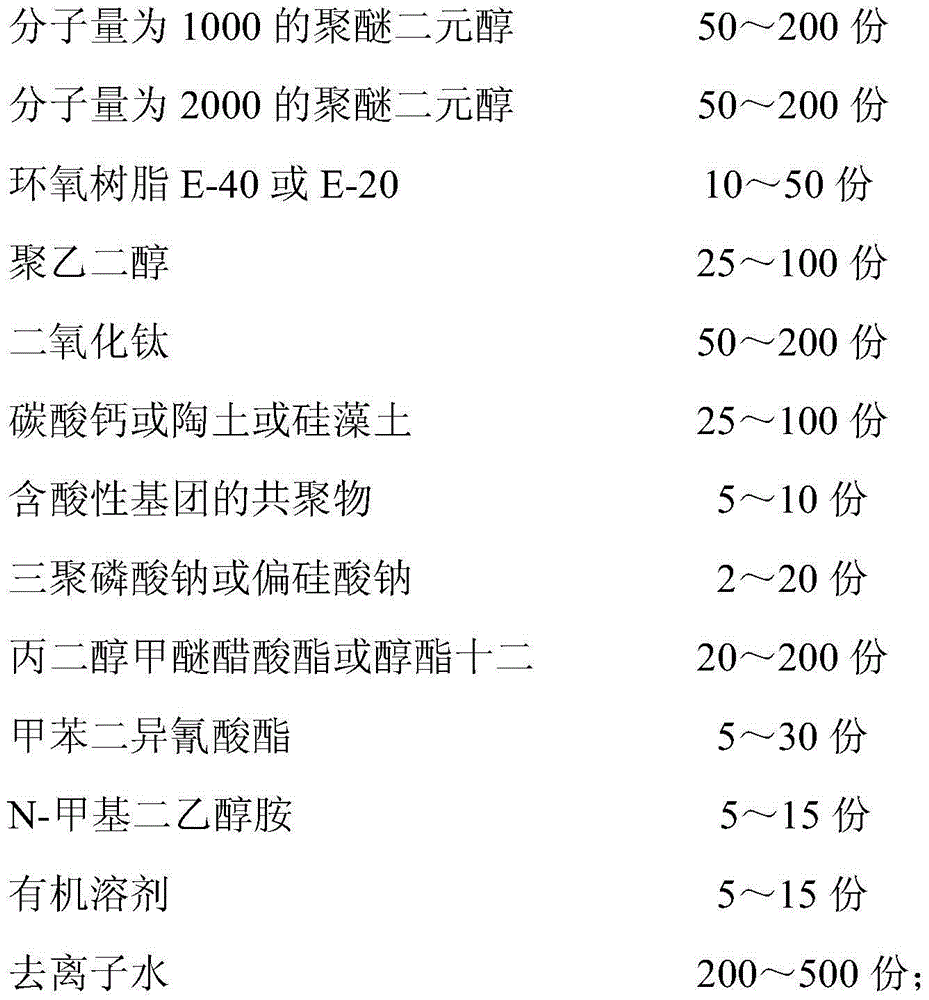

Method used

Image

Examples

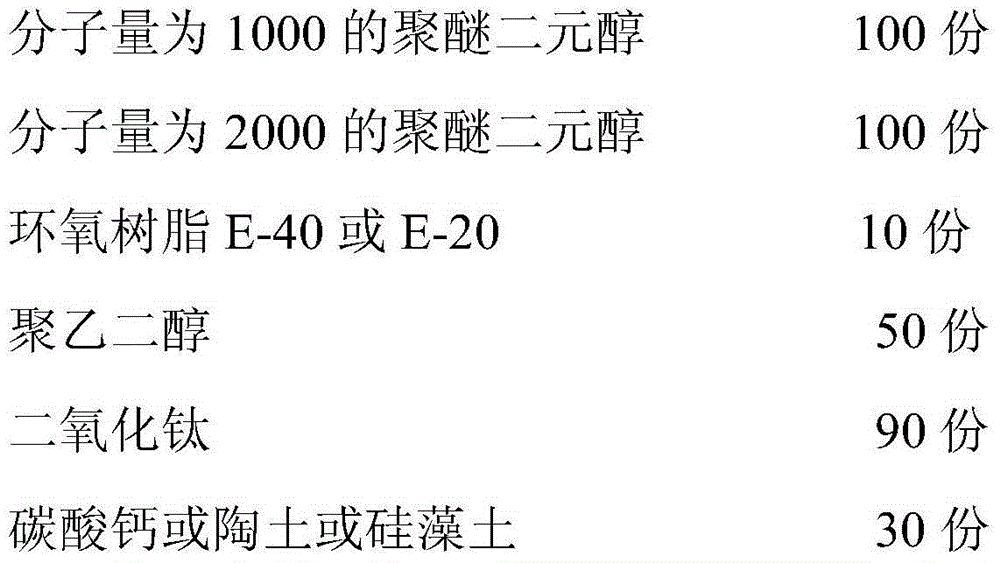

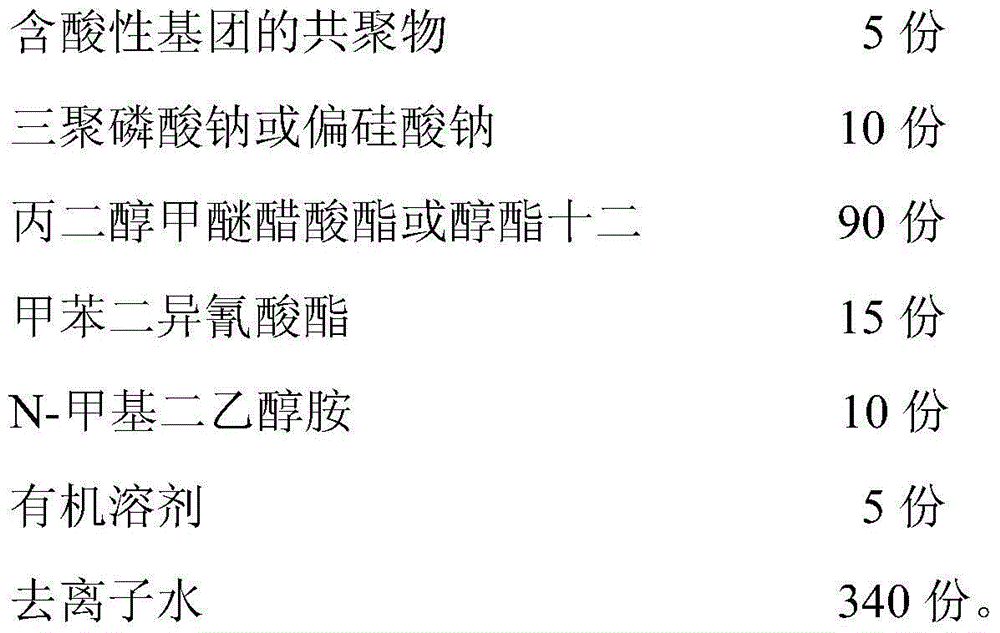

Embodiment 1

[0037] Under the protection of dry nitrogen, 100 parts by weight of polyether diol with a molecular weight of 1000, 100 parts by weight of polyether diol with a molecular weight of 2000, and 10 parts by weight of epoxy resin E-40 were mixed, and stirred at 2m / s Heating at high speed, then adding 15 parts by weight of toluene diisocyanate and 10 parts by weight of N-methyldiethanolamine, raising the temperature to 82°C, and keeping the temperature for 3 hours; then adding 90 parts by weight of propylene glycol methyl ether acetate, 3 parts by weight of organic solvent three Ethylamine, react at 65°C for 1h, finally add 50 parts by weight of polyethylene glycol, react at 60°C for 0.5h, cool down to below 40°C, and discharge to obtain a prepolymer;

[0038] Add 90 parts by weight of titanium dioxide, 30 parts by weight of calcium carbonate, 5 parts by weight of acid group-containing copolymer Disperbyk-110, 10 parts by weight of sodium tripolyphosphate, 2 parts by weight of organi...

Embodiment 2

[0042] Under the protection of dry nitrogen, 50 parts by weight of polyether diols with a molecular weight of 1000, 150 parts by weight of polyether diols with a molecular weight of 2000, and 15 parts by weight of epoxy resin E-20 were mixed, and stirred at 3m / s Heating at a high speed, then adding 10 parts by weight of toluene diisocyanate and 5 parts by weight of N-methyldiethanolamine, heating up to 80 ° C, and keeping the temperature for 3 hours; then adding 150 parts by weight of alcohol ester twelve, 2 parts by weight of organic solvent ethylene glycol Amine, react at 60°C for 1.5h, finally add 25 parts by weight of polyethylene glycol, react at 55°C for 1h, cool down to below 40°C, and discharge to obtain a prepolymer;

[0043] Add 50 parts by weight of titanium dioxide, 80 parts by weight of clay, 9 parts by weight of acid group-containing copolymer Disperbyk-110, 10 parts by weight of sodium metasilicate, 3 parts by weight of organic solvent ethylenediamine and 480 par...

Embodiment 3

[0047]Under the protection of dry nitrogen, 50 parts by weight of polyether diols with a molecular weight of 1000, 50 parts by weight of polyether diols with a molecular weight of 2000, and 50 parts by weight of epoxy resin E-40 were mixed. Heat up at a stirring speed, then add 15 parts by weight of toluene diisocyanate and 10 parts by weight of N-methyldiethanolamine, heat up to 85°C, and keep warm for 0.5h; then add 20 parts by weight of propylene glycol methyl ether acetate, 3 parts by weight of organic Solvent triethylamine, react at 60°C for 1h, finally add 80 parts by weight of polyethylene glycol, react at 60°C for 1h, cool down to below 40°C, and discharge to obtain a prepolymer;

[0048] Add 150 parts by weight of titanium dioxide, 25 parts by weight of diatomaceous earth, 10 parts by weight of acid group-containing copolymer Disperbyk-110, 15 parts by weight of sodium metasilicate, 5 parts by weight of organic solvent triethylamine and 230 parts by weight in the prepo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com