Semi-organic insulating coating paint for non-oriented silicon steel

An insulating coating, oriented silicon steel technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as poor adhesion, poor coating elasticity, and unachieved, and meet the requirements of environmental protection and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

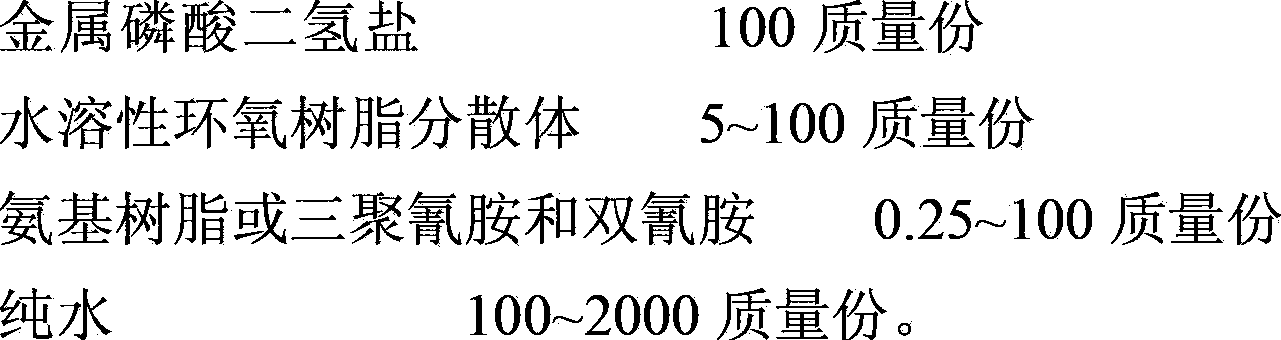

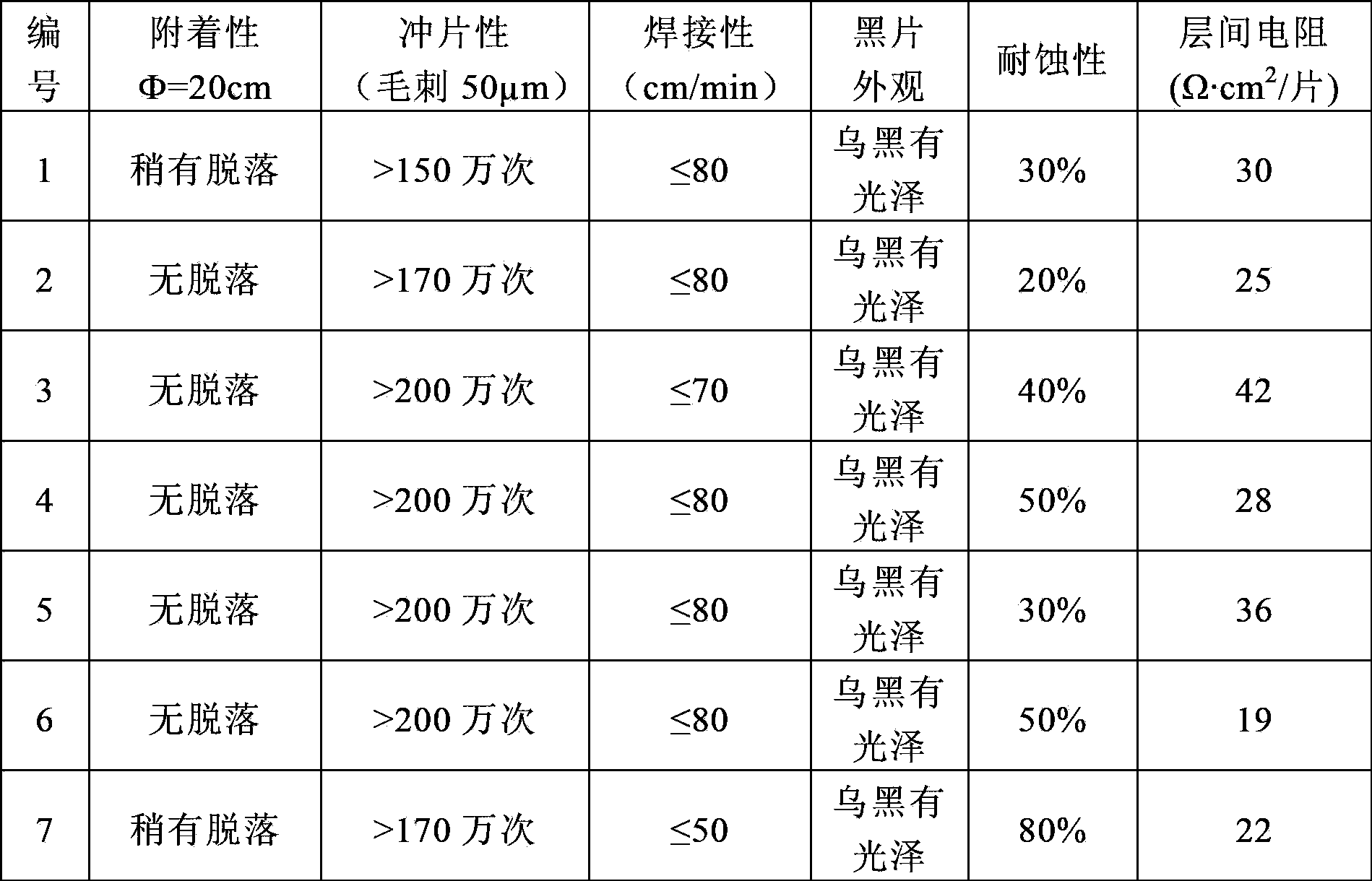

[0034] The coating composition is composed of aluminum dihydrogen phosphate solution, water-soluble epoxy resin solution and dicyandiamide. The water-soluble epoxy resin reacts with amino-containing compounds such as epoxy group and diethanolamine, 2-aminoethyl-2-hydroxyethyl ether, tris(hydroxymethyl)aminomethane, N-aminoethylpiperidine, It is then neutralized with phosphoric acid to form a water-soluble epoxy resin species that forms a salt. The composition of the chromium-free insulating coating solution is shown in Table 1. After the coating solution is mixed evenly by mechanical stirring, it is applied on the surface of the steel plate with a diameter of 0.5mm by a roller coater, and the coating amount is kept at 1.0g / m 2 , baked with an open flame, and baked into a film at a plate temperature of 200~500°C. The coating performance results are shown in Table 2.

[0035] Table 1 Unit: parts by mass

[0036]

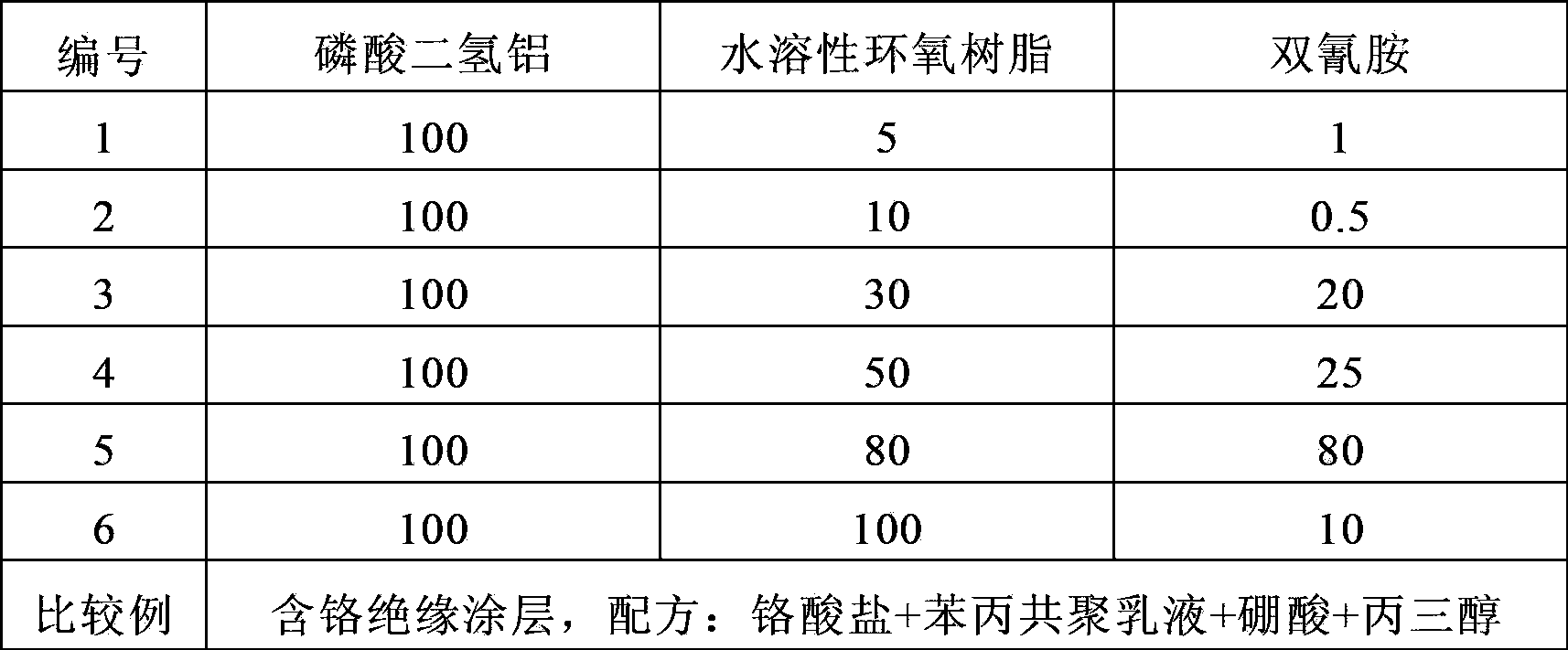

[0037] Table 2

[0038]

[0039] Note: (the same below)...

Embodiment 2

[0046] The phosphate component is made of aluminum dihydrogen phosphate and zinc dihydrogen phosphate. The water-soluble epoxy resin is a water-soluble epoxy resin variety formed by the reaction of epoxy groups with amino acids, aminobenzoic acid, aminobenzenesulfonic acid and other compounds. The curing agent Use methyl etherified melamine resin, add according to the ratio shown in Table 3, use mechanical stirring to dissolve each substance to form a chrome-free coating solution, use a roller coater to apply the coating solution on the surface of the steel plate after 0.5mm, keep the coating Application amount is 1.2g / m 2 , baked with an open flame, and baked into a film at a plate temperature of 200~500°C. The coating performance results are shown in Table 4.

[0047] Table 3 Unit: parts by mass

[0048]

[0049] Table 4

[0050]

[0051]

[0052] It can be seen from Table 4 that by using aluminum dihydrogen phosphate / zinc, water-soluble epoxy resin and methyl et...

Embodiment 3

[0054] The coating composition is composed of dihydrogen phosphate, water-soluble epoxy resin solution and curing agent. The water-soluble epoxy resin reacts with amino-containing compounds such as epoxy group and diethanolamine, 2-aminoethyl-2-hydroxyethyl ether, tris(hydroxymethyl)aminomethane, N-aminoethylpiperidine, It is then neutralized with phosphoric acid to form a water-soluble epoxy resin species that forms a salt. The curing agent adopts urea formaldehyde resin, melamine formaldehyde resin and benzomelamine formaldehyde resin.

[0055] The composition of the chromium-free insulating coating solution is shown in Table 5. After the coating solution is mixed evenly by mechanical stirring, it is applied on the surface of the steel plate with a diameter of 0.5mm by a roller coater, and the coating amount is kept at 1.1g / m 2 , baked with an open flame, and baked into a film at a plate temperature of 200~500°C. The coating performance results are shown in Table 2.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com