Method of recovering effective components from potassium clavulanate mixed powder

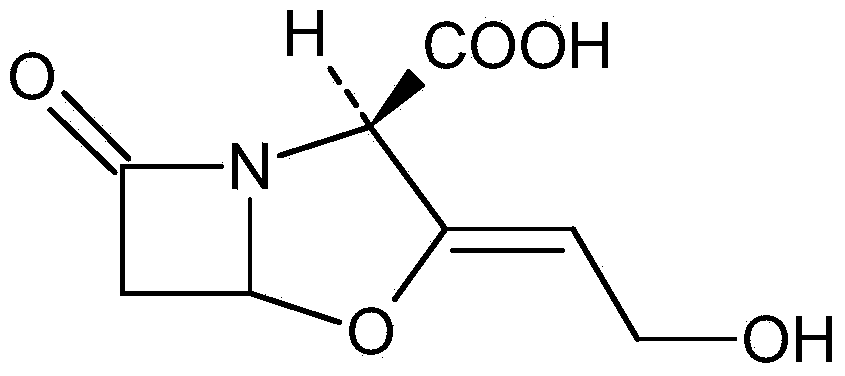

A technology described from potassium clavulanate and potassium clavulanate, which is applied in the field of recycling active ingredients, can solve problems such as unqualified products and economic losses, and achieve the effects of low cost, simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

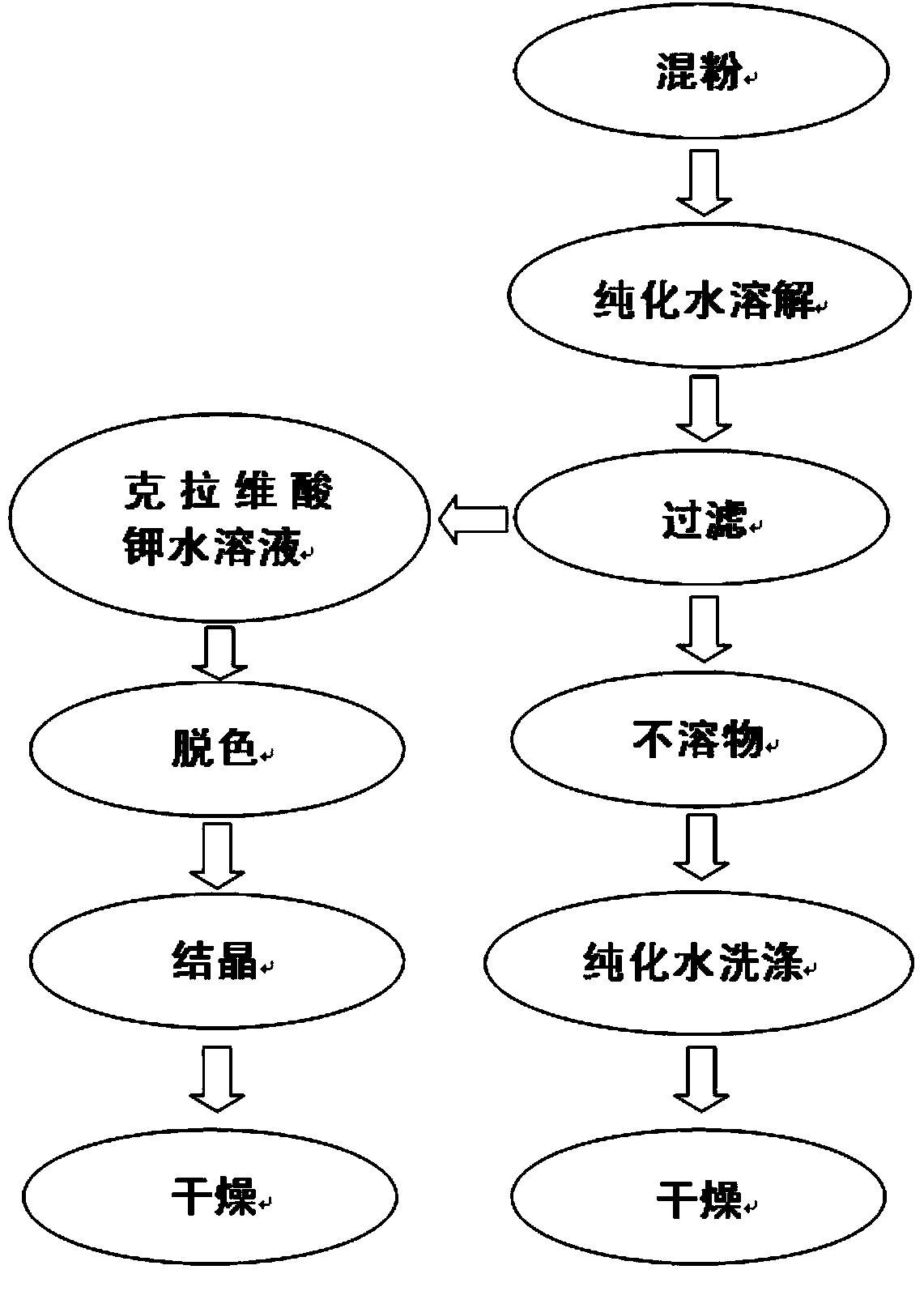

Method used

Image

Examples

Embodiment 1

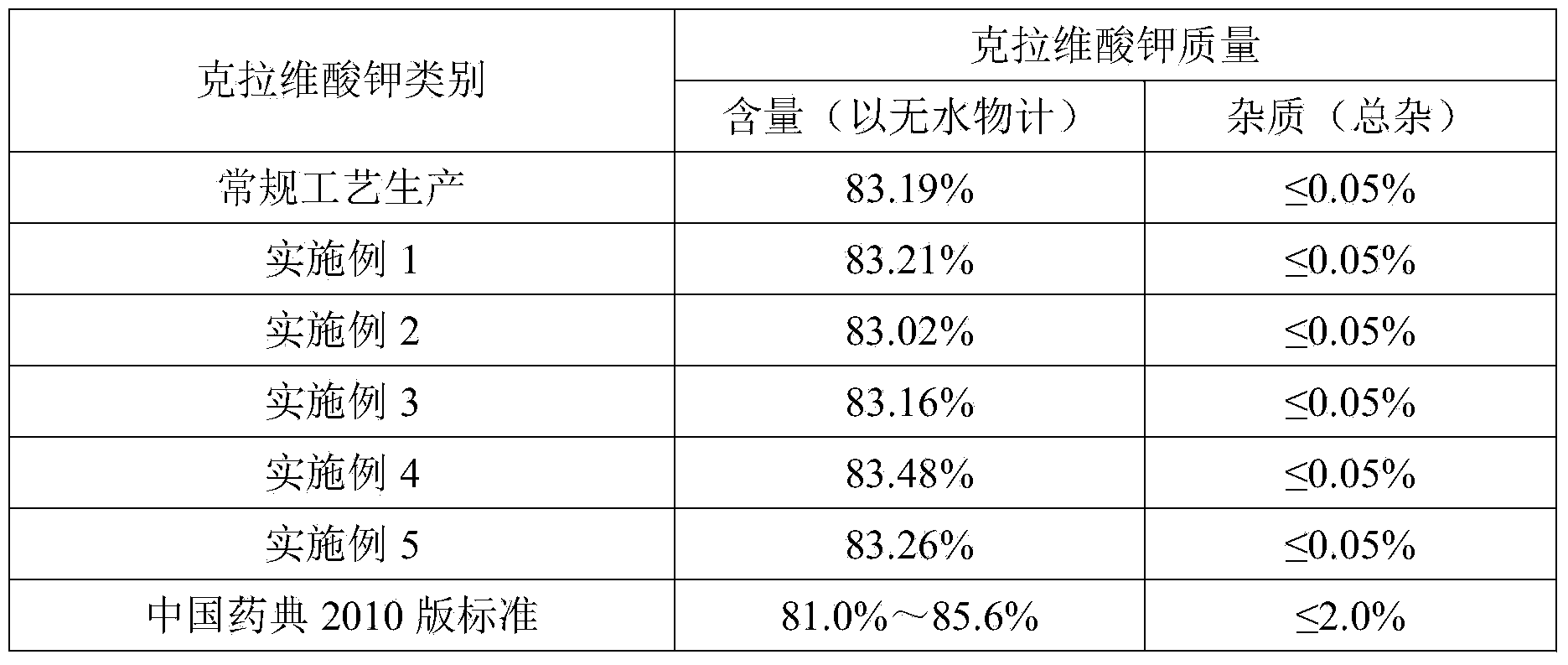

[0026] Take unqualified potassium clavulanate: silicon dioxide (1:1) mixed powder 200g, add 100mL purified water at 5°C, adjust pH to 5.0 with 15% acetic acid, stir to dissolve, filter to obtain clavulanate Aqueous solution of potassium phosphate and undissolved silica solid. The aqueous solution of potassium clavulanate is decolorized with 8g of activated carbon at 20°C, wherein the activated carbon is mixed with 767 type and 302 type according to the weight ratio of 2:1. In the decolorized potassium clavulanate aqueous solution, slowly add 20 times isopropanol for crystallization, the temperature is controlled at 0° C., and the crystal is grown with slow stirring for 2 hours. The crystallization solution was filtered, the crystals were washed three times with acetone, and vacuum-dried at 20°C to obtain 68.01 g of potassium clavulanate with a yield of 71.08%. Undissolved silica solids are not recovered due to their low economic value.

Embodiment 2

[0028] Take unqualified potassium clavulanate: microcrystalline cellulose (1:1) mixed powder 200g, add 50mL purified water at 20°C, adjust pH to 4.5 with 18% sulfuric acid, stir to dissolve, filter to obtain clavulanate Aqueous solution of potassium phosphate and undissolved microcrystalline cellulose solids. The aqueous solution of potassium clavulanate was decolorized with 12 g of 767 activated carbon at a temperature of 0°C. In the decolorized potassium clavulanate aqueous solution, slowly add 40 times of isopropanol for crystallization, the temperature is controlled at 5° C., and the crystal is grown with slow stirring for 2 hours. The crystallization solution was filtered, the crystals were washed three times with acetone, and vacuum-dried at 30°C to obtain 72.25 g of potassium clavulanate, with a yield of 76.00%. Undissolved microcrystalline cellulose solids are not recovered due to their low economic value.

Embodiment 3

[0030] Take unqualified amoxicillin: potassium clavulanate (2:1) mixed powder 200g, add 32mL purified water at 10°C, adjust pH 6.0 with 5% hydrochloric acid, stir to dissolve, filter to obtain clavulanic acid Aqueous solution of potassium and undissolved amoxicillin solid. The aqueous solution of potassium clavulanate is decolorized with 4g of activated carbon at 2°C, and the activated carbon is mixed with 772 type and 732 type according to the weight ratio of 1:1. In the decolorized potassium clavulanate aqueous solution, 45 times of acetone was slowly added for crystallization, the temperature was controlled at 3° C., and the crystal was grown with slow stirring for 2 hours. The crystallization solution was filtered, the crystals were washed three times with acetone, and vacuum-dried at 35°C to obtain 53.16 g of potassium clavulanate, with a yield of 78.02%. The undissolved amoxicillin solid was washed three times with 9.6 L of purified water, and then vacuum-dried at 50°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com