Wood-plastic composite of wood decorative sheet attaching veneer and preparation method thereof

A wood-plastic composite material and wood-plastic composite technology, applied in the field of wood-plastic composite materials and their preparation, can solve problems such as difficult bonding and lack of natural wood texture, achieve high environmental protection, avoid formaldehyde release problems, and have uniform and beautiful textures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

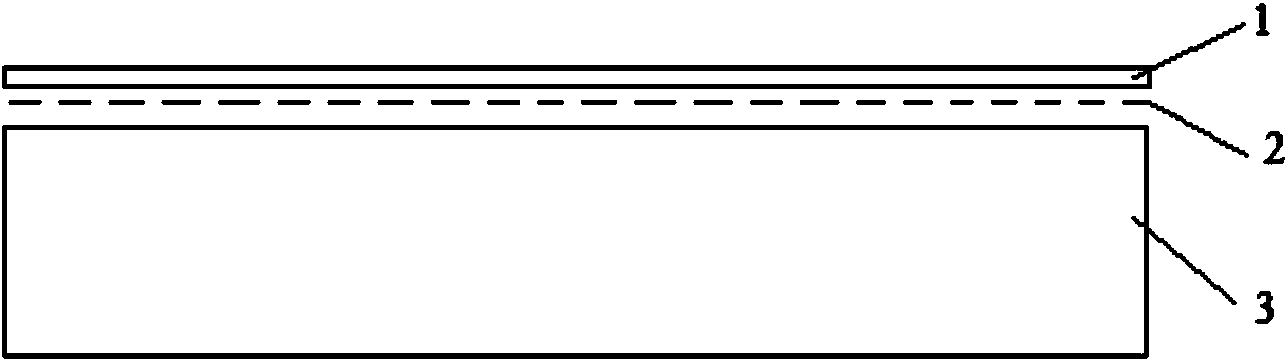

[0056] Specific Embodiment 1: In this embodiment, a wood-plastic composite material facing a wooden decorative board is made of wood-plastic composite boards, non-woven fabrics, wooden decorative boards and wood adhesives, or is made of wood-plastic composite boards, Made of non-woven fabric and wood trim.

[0057] Advantages of the wood-plastic composite material veneered by the wooden decorative board in this embodiment:

[0058] 1. In this embodiment, high-quality natural veneer and wooden veneer can be used as decorative materials, because wooden decorative materials have the advantages of uniform and beautiful texture and pleasing color, especially decorative veneer and veneer are made of natural high-quality tree species, which have extremely high decorative value , so the wooden feeling and added value of wood-plastic composite materials are improved.

[0059] 2. In this embodiment, non-woven fabric is used as the middle layer between the wood-plastic base material and...

specific Embodiment approach 2

[0064] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the wood-plastic composite board is prepared according to the following steps:

[0065] 1. Weigh 30-50 parts by mass of polyolefin, 40-70 parts of wood flour and 5-10 parts of filler, and mix them uniformly to obtain a mixed powder;

[0066] 2. Control the rotational speed of the twin-screw extruder to 30r / min-100r / min and the temperature of each barrel to 130°C-175°C, then melt and mix the mixed powder obtained in step 1 through the twin-screw extruder and extrude it , to obtain wood-plastic composite pellets;

[0067] 3. Control the speed of the single-screw extruder to 10r / min-100r / min and the temperature of each barrel to 130°C-175°C, add the wood-plastic composite pellets obtained in step 2 into the single-screw extruder and extrude Forming and cooling to obtain wood-plastic composite boards;

[0068] Wherein, the polyolefin described in step 1 is polyethylene, polypropylene or polyviny...

specific Embodiment approach 3

[0069] Specific embodiment three: The difference between this embodiment and specific embodiment one or two is that the filler described in step one is made of maleic anhydride grafted polyethylene, paraffin wax and polystyrene with a mass fraction ratio of 2:1:1. Composition of vinyl wax. Other parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com