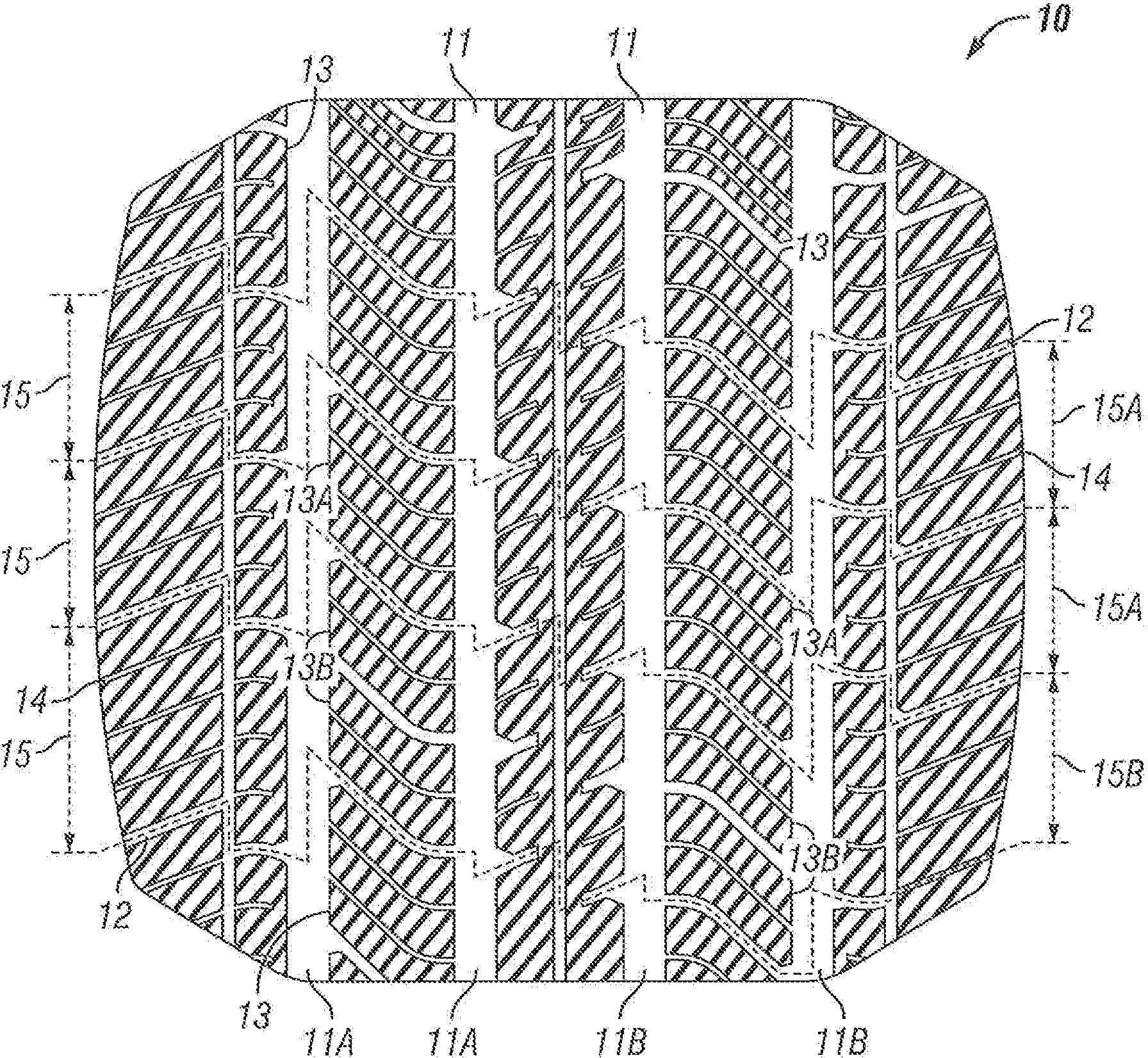

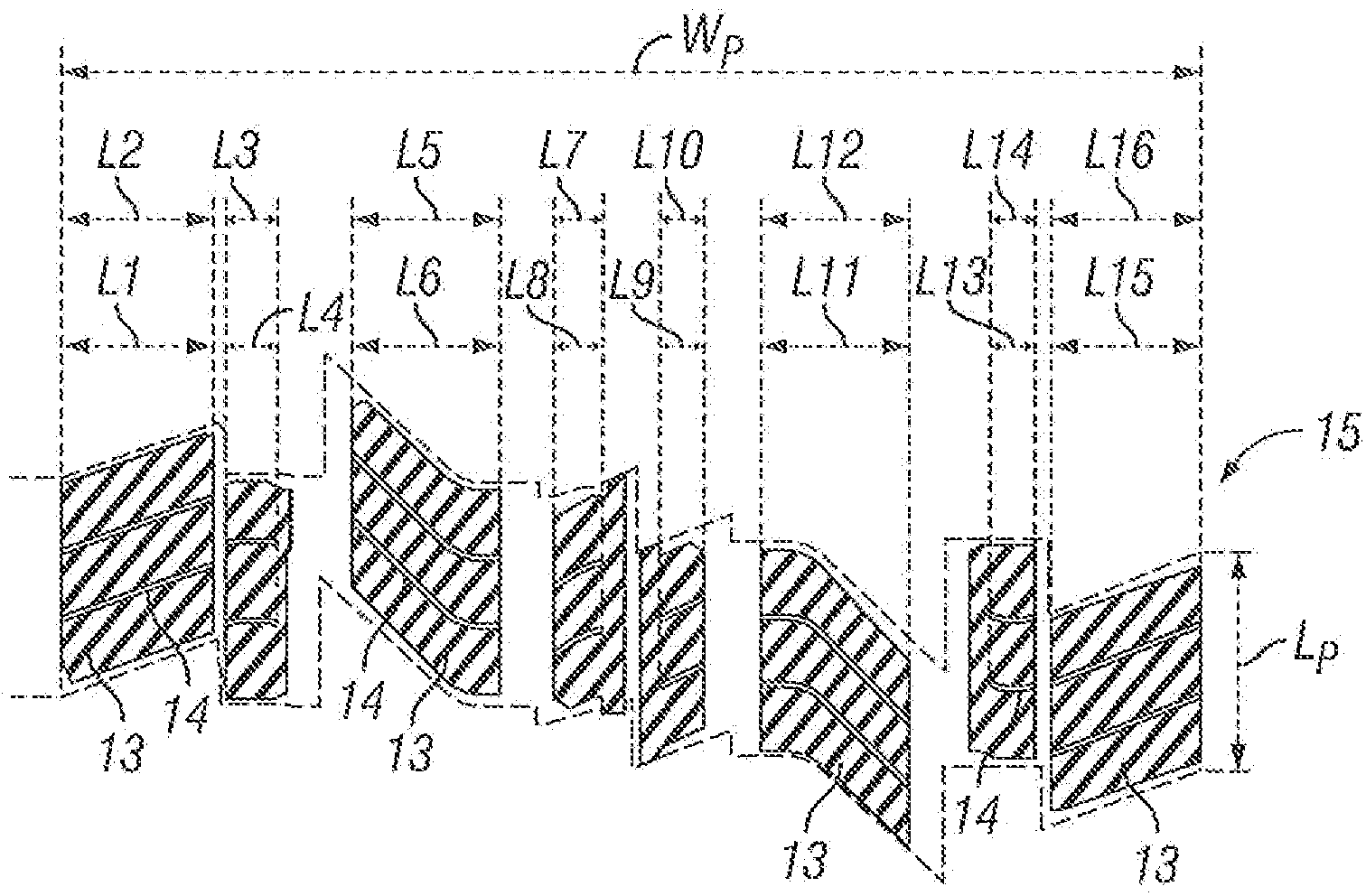

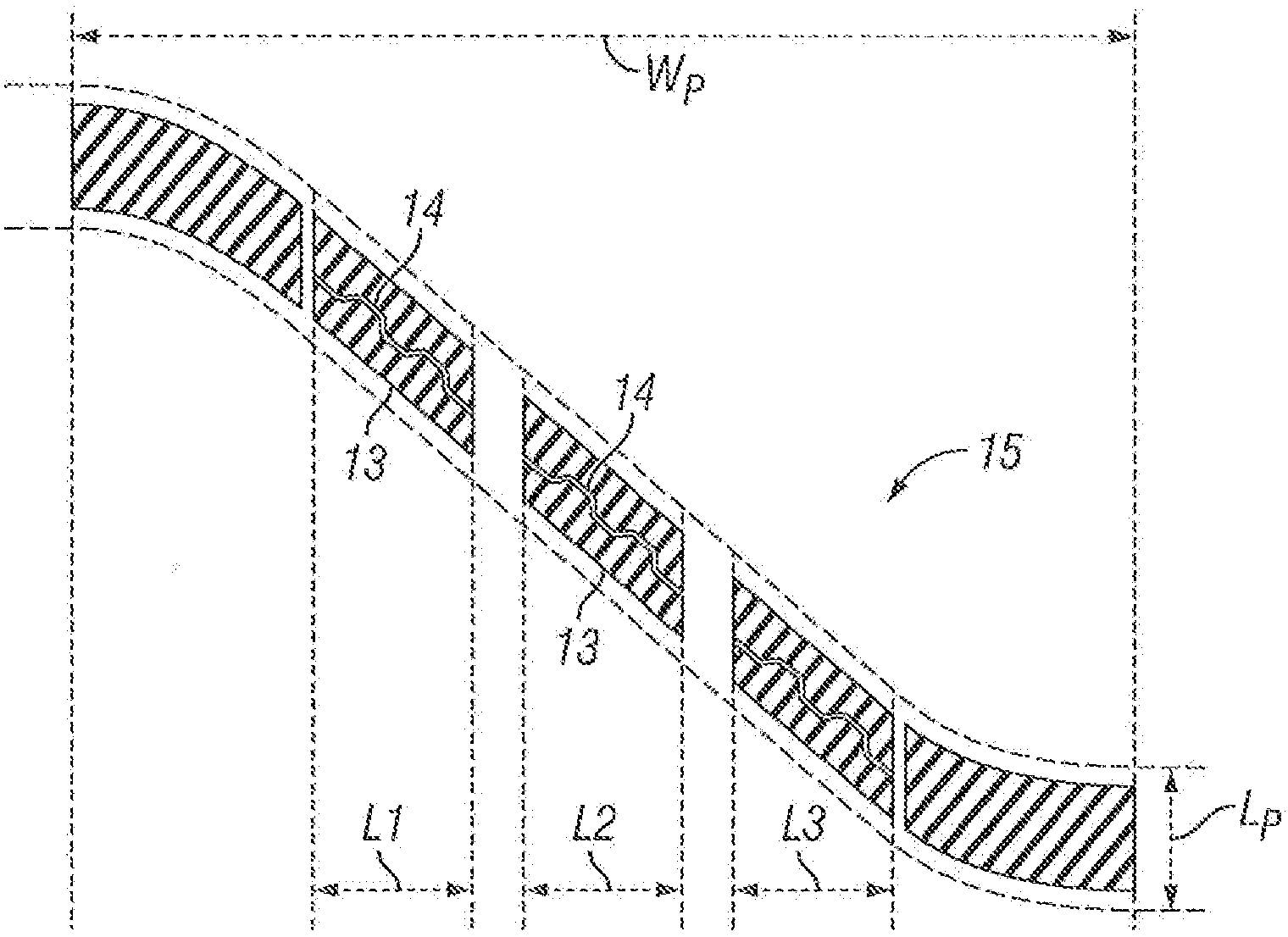

Tire tread with improved snow/dry traction

A tire tread and tread technology, applied in the direction of tire tread/tread pattern, special tires, tire parts, etc., can solve the problems of reduced dry braking performance, increased glass transition temperature of tread mixture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] Two successive stages of preparation (a first stage of thermomechanical processing at high temperature followed by a second stage of mechanical processing at a lower temperature) can generally be used, in a manner known to those skilled in the art at suitable A rubber composition as an example of the present invention was prepared in a mixer of .

[0085] The first stage of thermomechanical processing (sometimes referred to as the "non-production" stage) is intended to thoroughly mix by kneading the various ingredients of the composition, except the vulcanization system. This stage is carried out in suitable kneading equipment (such as internal mixers or extruders) until, under the action of mechanical processing and high shear applied to the mixture, a temperature of usually between 120°C and 190°C is reached, preferably Narrowly the maximum temperature is between 130°C and 170°C.

[0086] After the mixture has cooled, a second stage of mechanical processing is carrie...

example 1

[0104] Rubber compositions were prepared using the components shown in Table 1. The amounts of each component constituting the rubber composition shown in Table 1 are given in parts by weight per 100 parts by weight of rubber (phr). SBR is an oil extended rubber (with 10 phr MES) with a Tg of -27°C and BR has a Tg of -104°C.

[0105]The terpene resin was SYLVARES TR-5147, a polylimonene resin available from Arizona Chemical, Savannah, GA. The plasticizing oil is naphthenic and / or sunflower oil. Silica is ZEOSIL160, that is, BET is 160m 2 / g of highly dispersible silica available from Rhodia. The silane coupling agent was X50-S available from Evonik Degussa. The cure package contains sulfur, accelerators, zinc oxide and stearic acid.

[0106] Rubber formulations were prepared by mixing the components given in Table 1 (except sulfur and accelerators) in a Banbury mixer operating between 25 and 65 RPM until a temperature between 130°C and 170°C was reached. Accelerators and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com