Thinned energy storing device and manufacture process thereof

A technology of energy storage device and manufacturing process, which is applied in the direction of sustainable manufacturing/processing, electrode manufacturing, secondary battery manufacturing, etc. It can solve the problem that the shape and structure cannot be changed, the manufacturing process is complicated, and it cannot adapt to the connection and use of new flexible printed electronic products, etc. problems, to achieve the effects that are conducive to preparation and large-scale production, high electrochemical conversion rate, and conducive to integration and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

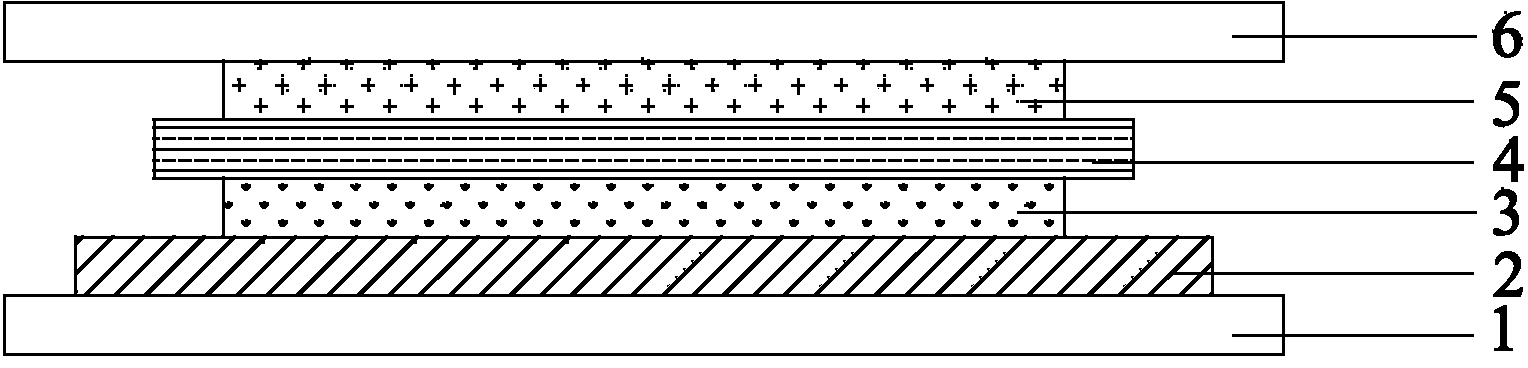

[0088] Print the conductive carbon paste on the packaging layer and dry it to make the collector layer; mix manganese dioxide, adhesive and KCl electrolyte to make the positive electrode layer material; use PP plastic film as the isolation layer material; paste the negative electrode zinc foil material on the PI pressure sensitive Adhesive film, and then align it with the rest of the fit.

Embodiment 2

[0090] Print the conductive carbon paste on the packaging layer and dry it to make the collector layer; mix nickel hydroxide, adhesive and KOH electrolyte to make the positive electrode layer material; use PP plastic film for the isolation layer material; paste the negative electrode copper foil material on the PE pressure sensitive Adhesive film, and then align it with the rest of the fit.

Embodiment 3

[0092] Print the conductive carbon paste slurry on the encapsulation layer and dry it to make the collector layer; Manganese dioxide, adhesive and ZnCl 2 The electrolyte is mixed to make the positive electrode layer material; the isolation layer material uses special paper; the negative electrode zinc foil material is pasted on the PET pressure-sensitive adhesive film, and then it is aligned with the rest.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com