Active vortex generator based on electromagnetic excitation

A vortex generator and electromagnetic vibration exciter technology, applied in the direction of fluid flow, vortex generation, drag reduction, etc., can solve the problems of limited flow control effect and weak local flow disturbance, and achieve good flow control effect and high adjustment freedom. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

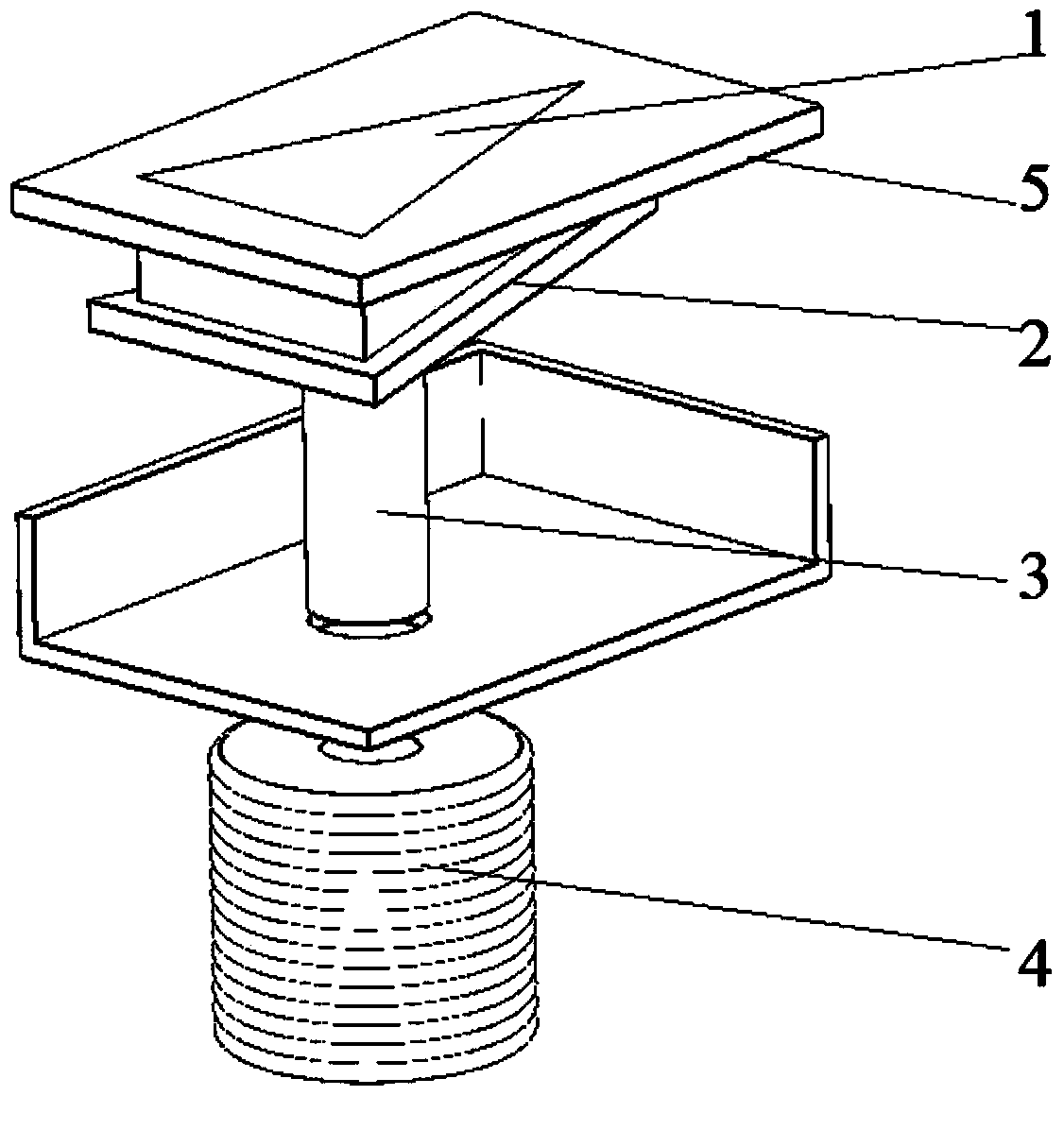

[0019] Such as figure 1 As shown, the present embodiment includes: a vibrating plate 1, a frame structure 2, a permanent magnet 3 and an electromagnetic exciter 4, wherein: the aircraft skin 5 is provided with a groove structure adapted to the cross-sectional shape of the vibrating plate 1, and the vibrating plate 1 is embedded in the groove structure, and its lower surface is provided with a frame structure 2 with a cross-sectional shape larger than the groove structure to prevent the vibrating piece 1 from falling off, and the bottom is fixedly connected with the permanent magnet 3. The horizontal plane of the aircraft skin 5 remains consistent, the electromagnetic exciter 4 is arranged below the permanent magnet 3, and a gap is provided between the two so that the vibrating piece 1 vibrates vertically;

[0020] Such as figure 2 As shown, the position of the vibrating plate 1 is located on the surface of the wing of the aircraft to control the stall of the wing and achieve...

Embodiment 2

[0028] The structure of this embodiment is the same as that of Embodiment 1, and the position of the vibrating piece 1 is as follows image 3 As shown, the position of the vibrating plate 1 is located in the leading edge cavity of the aircraft, which is for cavity noise control and achieves the effect of reducing noise. The arrow in the diagram indicates the direction of incoming flow.

[0029] The pilot manually or the avionics system automatically adjusts the voltage signal applied to the vibrating plate 1, which can control the position of the vibrating plate 1 to produce four states: maintain a flat state, protrude and maintain a stable state, a fixed frequency stretching vibration state, and a random frequency stretching vibration The first state is suitable for noise-free control; the latter three states are suitable for noise control, which can interfere with the turbulent flow of the shear layer inside the cavity, generate flow vortices, and suppress the shear layer and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com