A kind of flame-retardant nanoporous SIO2 multistage composite thermal insulation board and preparation method thereof

A nanoporous, thermal insulation board technology, applied in the field of building thermal insulation materials, can solve the problems of complex specific process and modification, limited large-scale application, thick composite material thickness, etc., and achieves excellent thermal insulation effect, excellent barrier effect, and good flexibility. and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

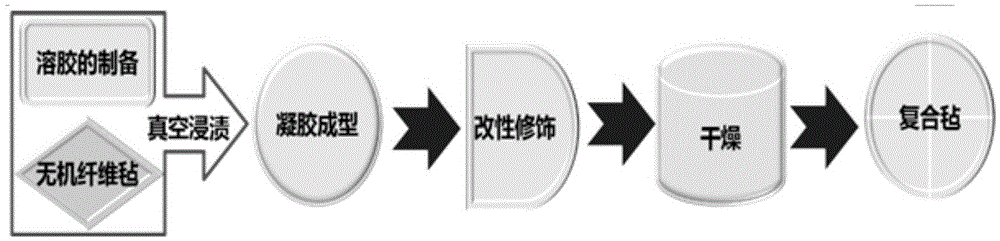

[0034] 1. Weigh 1.852g of ammonium fluoride (NH4F) and add it to 100mL of deionized water. Then weigh 20.5 g of ammonia solution and add it to the above solution to prepare ammonia water / ammonium fluoride acid-base buffer solution.

[0035] 2. Take 70g of deionized water and 86.8g of absolute ethanol, mix them uniformly, then add 3.64g of ammonia water / ammonium fluoride solution into it, and mix them uniformly by ultrasonic to obtain a catalyst solution. Take 47g of tetraethyl orthosilicate (TEOS), add it into 86.8g of absolute ethanol, and mix it uniformly by ultrasonic to obtain a precursor solution. Add the catalyst solution into the precursor solution, mix it uniformly by ultrasonic, and quickly pour it into a square mold equipped with 30cm*30cm*1mm inorganic fiber needle felt. Stand still for 5-30min to obtain a composite gel.

[0036] 3. Add an appropriate amount of absolute ethanol solution to the composite gel device and age for at least 24 hours, and change the etha...

Embodiment 2

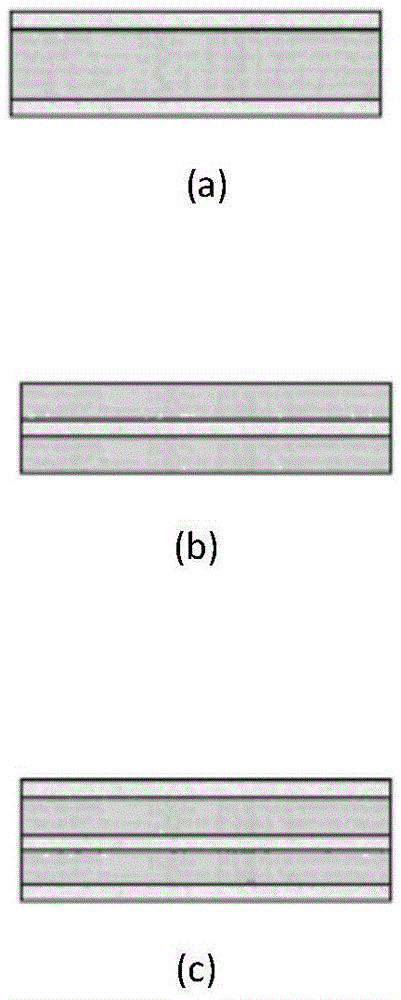

[0039] The first 1-3 steps are similar to Example 1. In the fourth step, a 30cm*30cm*1mm ultra-thin composite felt is fixed in the middle of the phenolic foam board mold, and the distance between the upper and lower surfaces is adjusted (about 15mm). Then, the phenolic foaming raw material is stirred and evenly coated on the upper and lower surfaces of the composite felt, and finally left to stand at room temperature for a period of time for foaming to form an integrally formed single-layer inorganic composite felt and double-layer phenolic foam composite sandwich panel.

Embodiment 3

[0041] The overall process is similar to Example 1, except that in the 4th step, the phenolic foamed sheet is replaced with a polyurethane foamed sheet. A single-layer polyurethane foam composite board covered by an integrally formed double-layer inorganic composite felt can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com