Method for banking with silt filled geotextile bags

A technology of geotextile bags and fabric bags, applied in soil protection, embankment, construction, etc., can solve the problems of low foundation bearing capacity, slow drainage and consolidation of silt, etc., and achieve high bearing capacity, good soil retention, and porosity small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

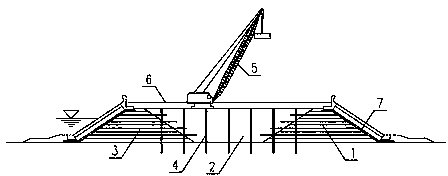

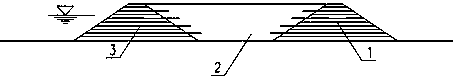

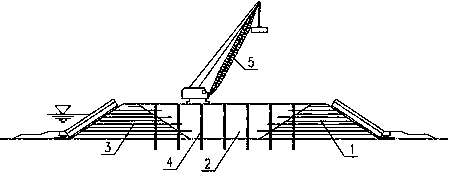

[0011] The present invention adopts the embankment (see figure 1 ), the content of particles with a particle size greater than 0.075mm in the silt does not exceed 50% of the total mass, and the plasticity index of the silt is not greater than 10; geotextile bags (see Figure 4 ) Composite geotextile 8 is used on the side, woven fabric 9 is used on the upper and lower sides, and the composite geotextile is 150~250g / m 2 woven fabric with 100~250g / m 2 It is made of composite non-woven geotextile, and the specification of the woven fabric is 150~300g / m 2 The two sides of the constructed embankment are prisms 1 made of geotextile bags filled with silt, the middle of the dam is a blow-filled silt embankment core 2, and horizontal plastic drainage boards 3 are buried between the geotextile bags filled with silt. Connect the core of the dredged silt embankment and the outside of the prism to form a horizontal drainage channel, and the horizontal spacing of plastic drainage boards is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com