Heat-preserving electrolytic tank

A technology of electrolytic cells and heat preservation covers, which is applied in the field of heat preservation electrolytic cells, can solve the problems of affecting the workshop environment, high labor intensity, and large heat loss, and achieve the effects of improving environmental benefits, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

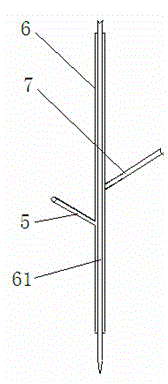

[0021] The thermal insulation electrolytic cell provided by the present invention comprises a cell body 1 and its upper part, an anode carbon block 10 fixed on the cell body 1, a gas collecting hood 8 fixed on the upper part of the cell, and a feeding pipe fixed in the middle of the gas collecting hood 8 6. The shelling hammer 61 passing through the feeding pipe 6, the upper end of the shelling hammer 61 is connected to the power cylinder, the side roof and side wall of the tank body 1 are movable insulation tank covers 2, and the anode carbon block 10 is fixed on the horizontal bus bar at the upper part of the tank 11, the top of the tank body 1 is provided with a thermal insulation cover 3, and the thermal insulation cover 3 is connected with the gas collection cover 8 through the connector 4, as figure 1 , 4 The movable heat preservation tank cover 2 comprises a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com