A kind of extraction agent for nickel electrolytic anolyte to remove copper, its preparation method and application

An extractant and nickel electrolysis technology, which is applied in the field of non-ferrous metal hydrometallurgy, can solve the problems of emulsification and easy degradation, and achieve the effects of high yield, high selectivity of copper and nickel separation, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

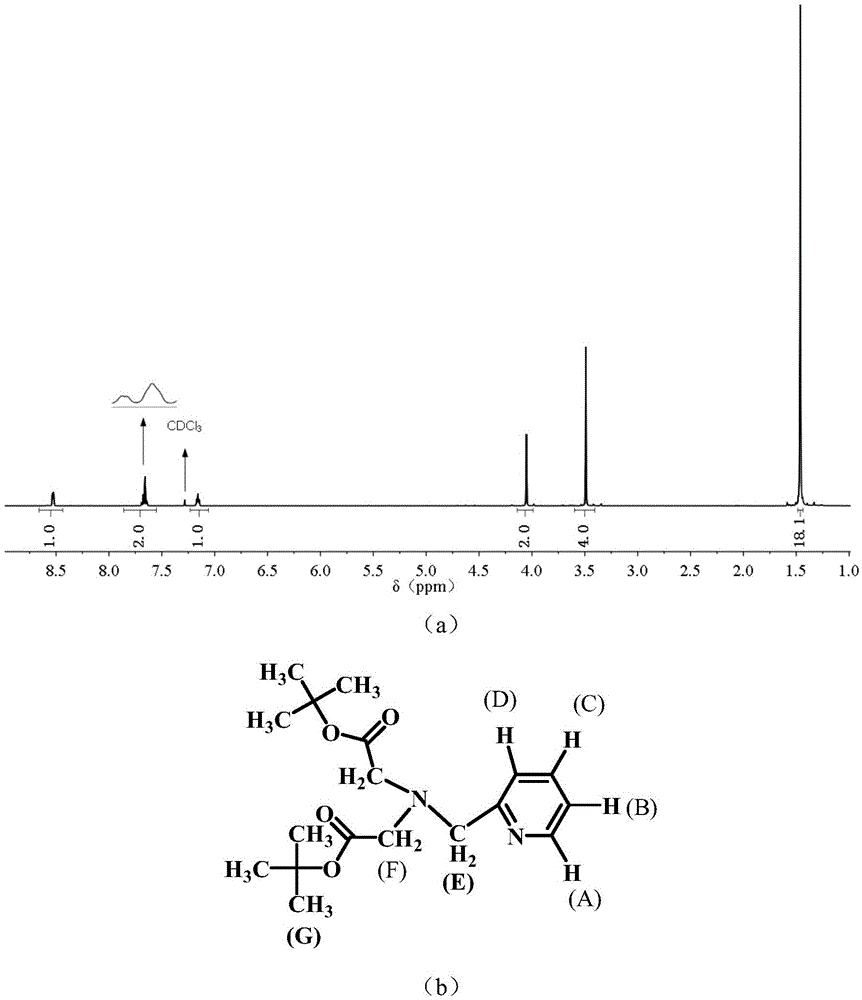

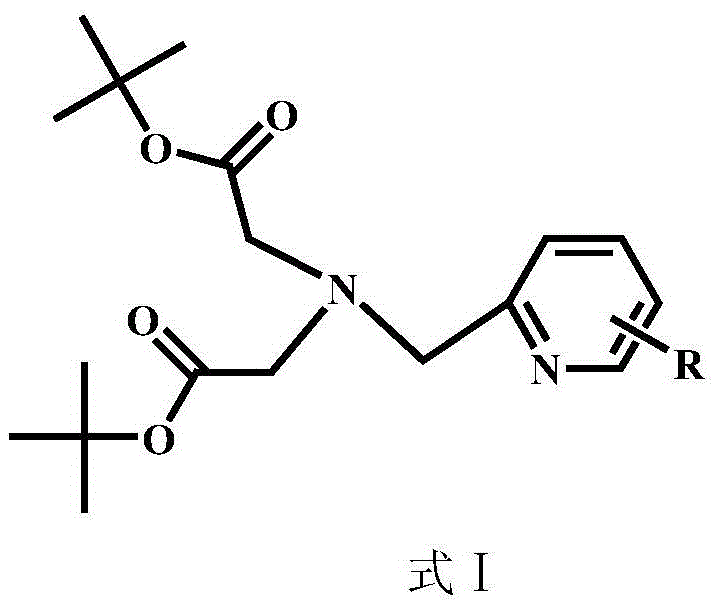

[0037] In N 2 Add 2-aminomethylpyridine, triethylamine and absolute ethanol to the three-necked flask under the protection of the atmosphere. Stir magnetically at room temperature. Use a constant pressure dropping funnel to add a certain amount of tert-butyl bromoacetate (the molar ratio of 2-aminomethylpyridine to tert-butyl bromoacetate is 1:(2~2.25)), and then slowly react The system is heated to 60-80°C and reacted for 4-8 hours. After the system is cooled to room temperature, add water, extract with ethyl acetate, combine the organic phases, dry the organic phases with anhydrous magnesium sulfate, filter, and evaporate the filtrate to dryness and pass through silica gel column chromatography (eluent: V (ethyl acetate): V(n-hexane)=2:1) Purified extractant [N,N-bis(tert-butoxycarbonylmethylene)-2 picolylamine], the yield is 60%-65%.

[0038] Table 1 Preparation of extractant [N,N-bis(tert-butoxycarbonylmethylene)-2 picolylamine]

[0039]

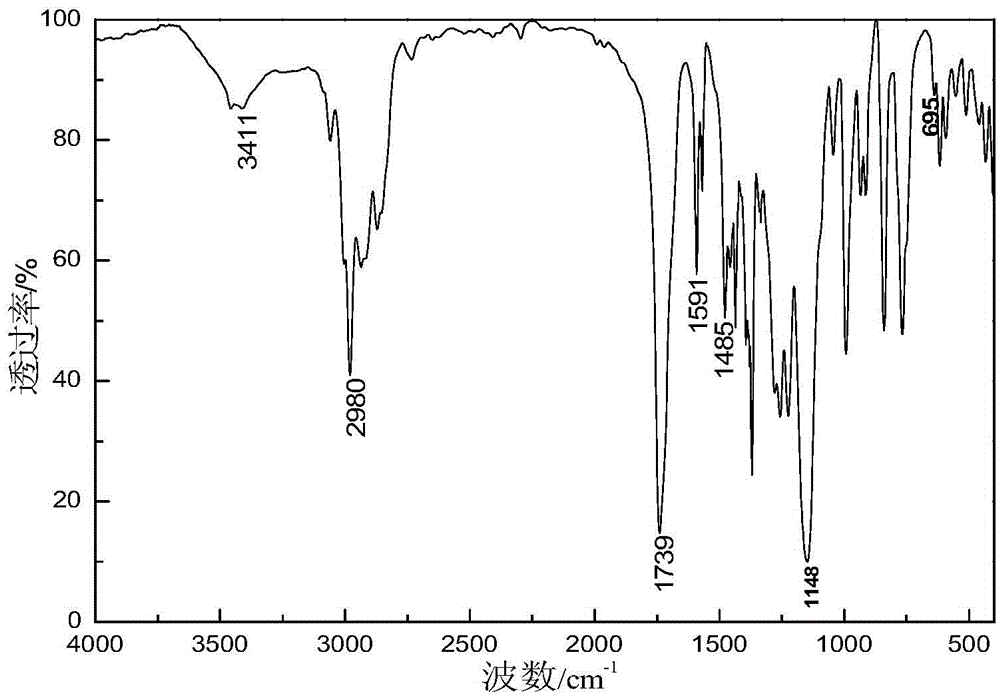

[0040] The product N,N-bis(tert-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com